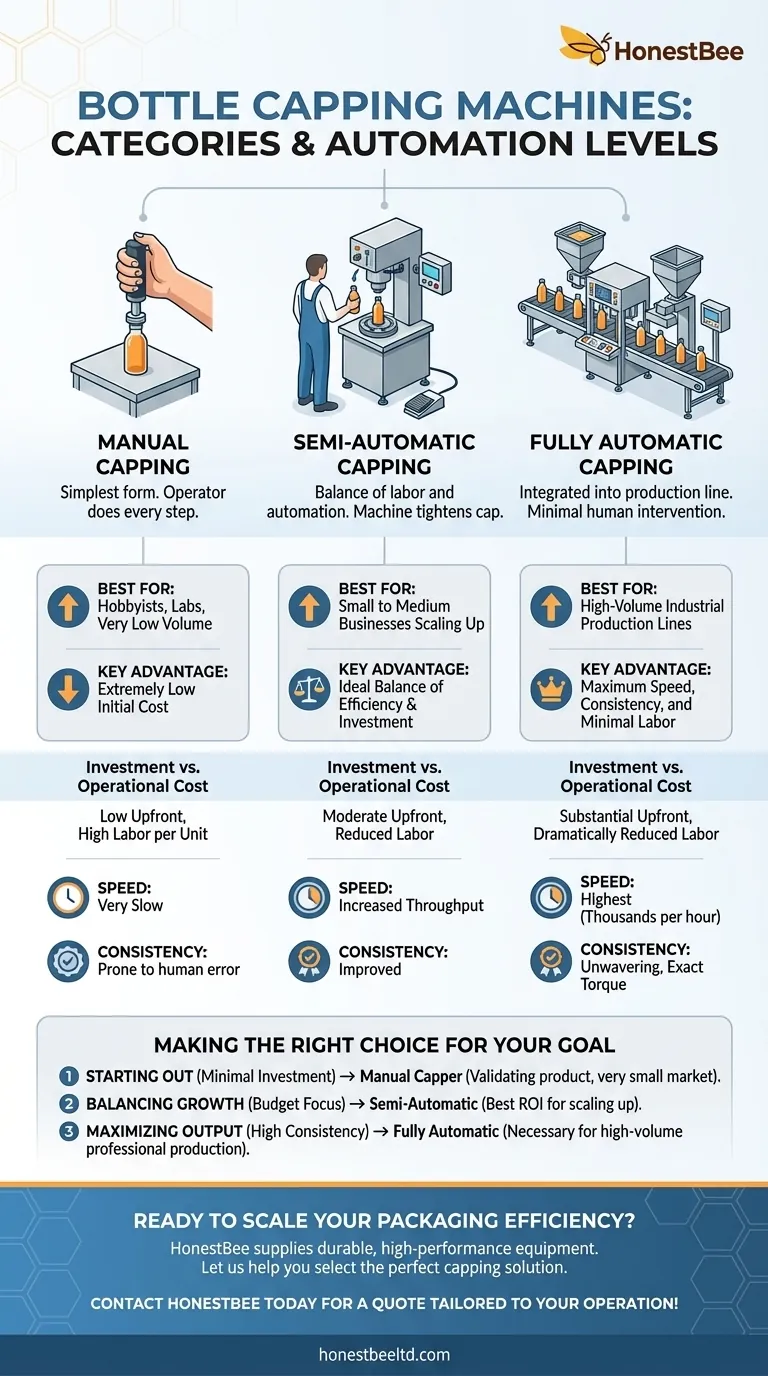

The primary categories of bottle capping machines are defined by their level of automation: manual, semi-automatic, and fully automatic. Each category is engineered to serve a distinct production scale, from small-batch artisan operations to high-volume industrial packaging lines.

Choosing the right capping machine is a strategic decision that balances your required production volume, ongoing labor costs, and upfront capital investment. The correct choice aligns with your operational needs and supports your business's growth trajectory.

A Closer Look at Each Automation Level

Understanding the operational differences between each category is the first step in identifying the right solution for your production line.

Manual Capping Machines

Manual cappers are the simplest form of capping equipment, requiring an operator for every step of the process. The operator places the cap on the bottle and then uses a handheld or bench-mounted tool to tighten it.

These machines are best suited for hobbyists, lab settings for testing, or businesses with very low production volumes. Their primary advantage is their extremely low initial cost.

Semi-Automatic Capping Machines

Semi-automatic machines strike a balance between manual labor and full automation. Typically, an operator places the cap on the bottle and positions it in the machine. The machine then automatically performs the tightening action.

This category is the ideal choice for small to medium-sized businesses looking to increase their output and improve consistency over manual methods. It represents a significant step up in efficiency for a moderate investment.

Fully Automatic Capping Machines

Fully automatic cappers are designed for integration into a complete production line and require minimal human intervention. Bottles move along a conveyor, where a mechanism automatically sorts, places, and tightens the caps.

These systems are essential for large-scale manufacturing and industrial facilities where high speed and unwavering consistency are critical. They handle thousands of units per hour with precision.

Understanding the Trade-offs

Selecting a machine isn't just about its function; it's about the economic and operational implications for your business.

Investment vs. Operational Cost

There is a direct trade-off between the initial purchase price and the long-term labor cost. Manual machines have a negligible upfront cost but the highest labor cost per bottle. Fully automatic machines require a substantial capital investment but dramatically reduce per-unit labor costs.

Speed and Production Volume

Each category is built for a different output level. Manual capping is very slow, while semi-automatic systems can significantly increase an operator's throughput. Fully automatic systems operate at the highest speeds, making them the only option for mass production.

Consistency and Quality

Automation directly improves the quality and consistency of the seal. Manual capping is prone to human error, resulting in inconsistent torque. Automated systems apply the exact same torque to every cap, reducing leaks, product spoilage, and defects.

Making the Right Choice for Your Goal

Your ideal machine depends directly on your production scale, budget, and quality requirements.

- If your primary focus is starting out with minimal investment: A manual capper is the most accessible entry point for validating a product or serving a very small market.

- If your primary focus is balancing growth with a budget: A semi-automatic machine provides the best return on investment for an operation scaling up its production.

- If your primary focus is maximizing output and consistency: A fully automatic machine is the necessary solution for any high-volume, professional production line.

Selecting the right level of automation is fundamental to creating an efficient and scalable packaging process.

Summary Table:

| Automation Level | Best For | Key Advantage |

|---|---|---|

| Manual | Hobbyists, labs, very low volume | Extremely low initial cost |

| Semi-Automatic | Small to medium businesses scaling up | Ideal balance of efficiency and investment |

| Fully Automatic | High-volume industrial production lines | Maximum speed, consistency, and minimal labor |

Ready to Scale Your Packaging Efficiency?

Choosing the right capping machine is crucial for your production line's success. At HONESTBEE, we supply durable, high-performance beekeeping supplies and equipment to commercial apiaries and distributors through our wholesale-focused operations. We understand the demands of scaling a business and can help you select the perfect capping solution to boost your output, ensure consistent quality, and optimize your costs.

Contact HONESTBEE today to discuss your needs and get a quote tailored to your operation!

Visual Guide

Related Products

- Semi-Automatic Pneumatic Bottle Capping Machine by HONESTBEE

- Semi Automatic Electric Bottle Capping Machine

- Automatic In-Line Round Bottle Labeling Machine

- Professional Water Cooled Induction Sealing Machine for Bottles and Containers

- Semi Automatic Round Bottle Labeling Machine

People Also Ask

- What types of caps can capping machines handle? Find the Right Solution for Your Bottling Line

- Which machine is used for sealing of bottles? Choose the Right Capper for Your Production Line

- Can you bottle honey right after extraction? Weighing Speed vs. Quality for Your Apiary

- How does a bottle machine work? Master the Automated Bottling Process

- What are the main types of caps supported by bottle capping equipment? Threaded, Press-On, and Insertion

- What is the purpose of bottle capping equipment and what types are available? Professional Sealing Solutions

- What is the function of a capping machine in honey packaging? Secure Your Product Quality and Shelf Life

- What is the purpose of a bottle capping machine? Boost Efficiency and Ensure Product Integrity