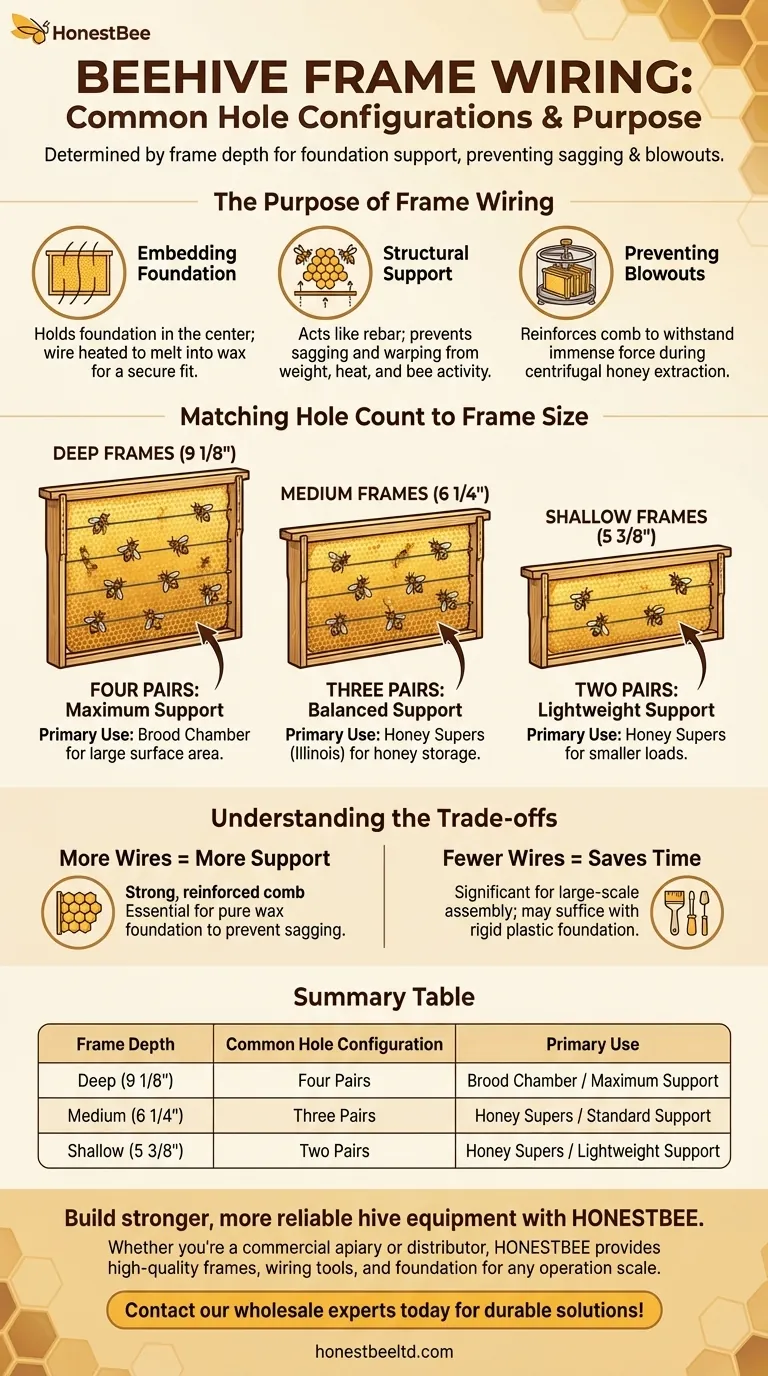

The most common hole configurations for wiring beehive frames are four pairs, three pairs, or two pairs of holes punched into the end bars. The specific number of holes is not arbitrary; it is determined by the depth of the frame to ensure the foundation has adequate support.

The core principle is simple: the deeper the frame, the more horizontal wires it needs to properly support the wax or plastic foundation. This prevents sagging in warm weather and blowouts during honey extraction.

The Purpose of Frame Wiring

Wiring is the process of running thin wire horizontally across a bee frame. This creates a supportive structure that serves a critical purpose.

Embedding Foundation

The primary goal of wiring is to hold a sheet of foundation in the center of the frame. For wax foundation, a small electric current is often used to heat the wire, allowing it to melt slightly into the wax, securing it firmly.

Providing Structural Support

The wires act like rebar in concrete. They prevent the delicate wax foundation from sagging, warping, or bulging under its own weight, the weight of the bees, and the heat of the hive.

Preventing Blowouts

During honey extraction in a centrifugal extractor, the force exerted on the honeycomb is immense. Proper wiring provides the necessary reinforcement to prevent the comb from breaking apart.

Matching Hole Count to Frame Size

The number of holes is directly correlated with the standard sizes of hive equipment used in beekeeping.

Four Pairs of Holes: Deep Frames

Frames intended for deep hive bodies (9 1/8 inches) almost always have four pairs of holes. This provides the maximum support needed for the large surface area of these frames, which are typically used for the brood chamber.

Three Pairs of Holes: Medium Frames

Frames for medium supers (6 1/4 inches), also known as "Illinois supers," are the most common size for honey storage. They typically utilize three pairs of holes, offering a balance of strong support for heavy honeycombs without excessive wiring time.

Two Pairs of Holes: Shallow Frames

Frames for shallow honey supers (5 3/8 inches) require the least support due to their smaller size. Consequently, they are drilled with just two pairs of holes.

Understanding the Trade-offs

While the frame depth is the primary guide, understanding the implications of wiring helps in making informed decisions.

More Wires Equals More Support

Using the maximum number of wires for a given frame size provides the best possible structural integrity. This is especially critical if you are using pure wax foundation, which is more prone to sagging than wire-reinforced or plastic foundation.

Fewer Wires Saves Time

For beekeepers assembling hundreds of frames, the time saved by using fewer wires can be significant. Using plastic foundation, which has its own rigidity, may allow a beekeeper to get by with fewer wires than recommended, though this is not standard practice.

How to Apply This to Your Hive

Your choice is largely dictated by the equipment you use, but your beekeeping philosophy also plays a role.

- If your primary focus is the brood chamber: You will be using deep frames, so always choose the four-hole configuration to give the queen the best possible laying surface.

- If your primary focus is honey production with medium supers: Three-hole frames are the industry standard and provide excellent support for heavy honeycombs during extraction.

- If you use shallow supers or plastic foundation: Two-hole frames are sufficient for shallow boxes, and some beekeepers may opt for fewer wires on larger frames if using rigid plastic foundation.

Ultimately, matching the hole configuration to the frame depth is a fundamental step in building durable equipment that serves both you and your bees effectively.

Summary Table:

| Frame Depth | Common Hole Configuration | Primary Use |

|---|---|---|

| Deep (9 1/8") | Four Pairs | Brood Chamber / Maximum Support |

| Medium (6 1/4") | Three Pairs | Honey Supers / Standard Support |

| Shallow (5 3/8") | Two Pairs | Honey Supers / Lightweight Support |

Build stronger, more reliable hive equipment with the right supplies. Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE provides the high-quality frames, wiring tools, and foundation you need to match the perfect hole configuration to your operation's scale. Ensure your frames are built to last—contact our wholesale experts today for durable beekeeping solutions!

Visual Guide

Related Products

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

- Plastic Bee Frame Beekeeping Hive Frames for Wholesale

- HONESTBEE Professional Frame Wiring Board and Jig

- Manual Spur Wheel Wire Embedder for Foundation

People Also Ask

- How do wooden frames perform during honey extraction? Superior Rigidity for a Smoother Harvest

- What are the small wooden 'frames' used for in beekeeping? Essential Tools for Hive Organization and Honey Storage

- How are Langstroth beehive frames assembled? A Step-by-Step Guide for a Durable Hive

- When should I throw away my bee frame? A Guide to Hive Health & Frame Rotation

- What is the process for assembling and gluing a Langstroth beehive frame? Build Durable Hives for Your Apiary