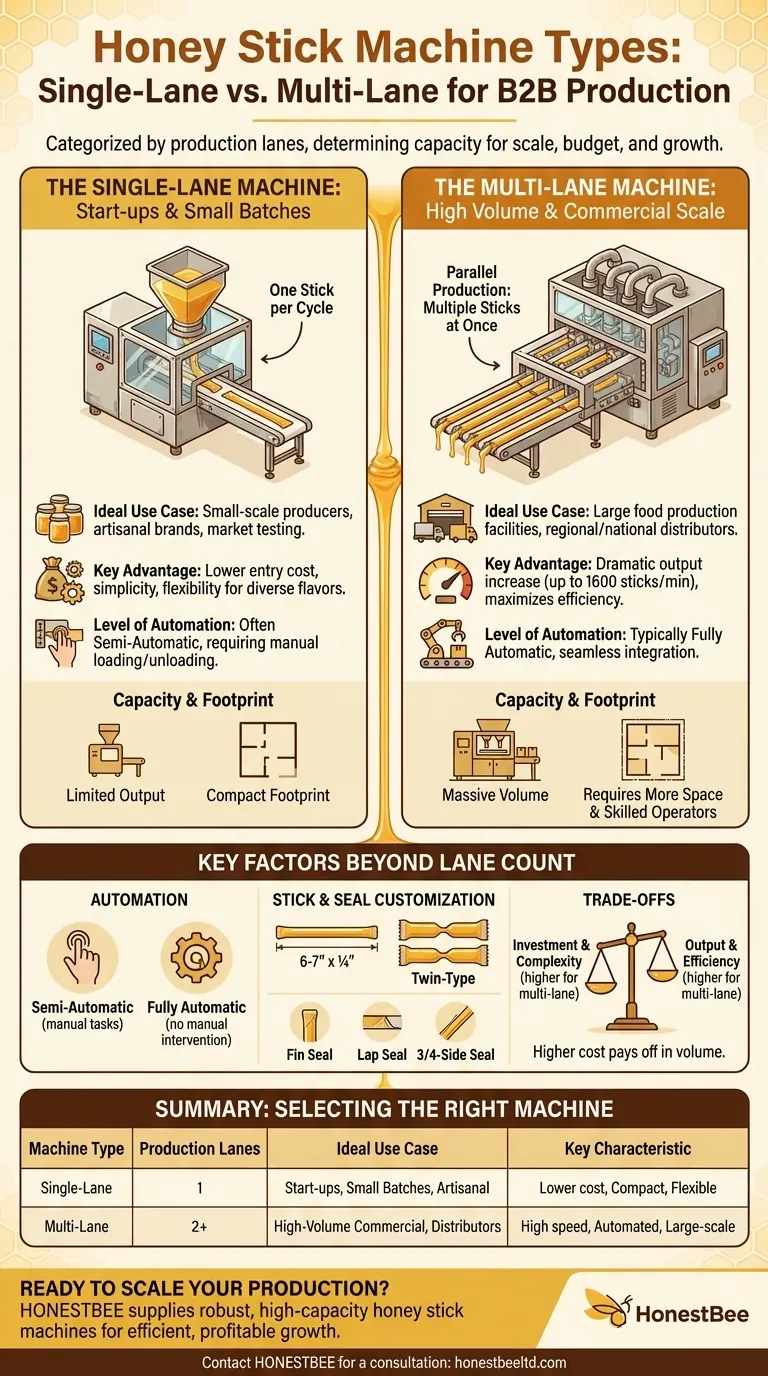

At its core, honey stick machines are categorized into two primary types based on their production lanes: single-lane and multi-lane. Single-lane machines are designed for smaller operations, producing one stick per cycle, while multi-lane machines are built for high-volume commercial production, creating multiple sticks simultaneously.

The number of lanes in a honey stick machine is the most direct indicator of its production capacity. Your choice between a single-lane and a multi-lane model is fundamentally a decision about your business's scale, budget, and growth ambitions.

The Single-Lane Machine: For Start-ups and Small Batches

How It Works

A single-lane machine operates on a simple principle: it forms, fills, and seals one honey stick at a time with each cycle of the machine.

Ideal Use Case

This type of machine is the standard choice for small-scale producers, artisanal honey businesses, or companies testing new products. Its simplicity and lower entry cost make it ideal for proving a market before scaling up.

The Multi-Lane Machine: Scaling for High Volume

The Principle of Parallel Production

Multi-lane machines are engineered for efficiency, featuring two or more lanes that work in parallel. Each lane performs the forming, filling, and sealing process simultaneously.

Significant Output Increase

This parallel operation dramatically increases throughput. While a single-lane machine is limited to one stick per cycle, some multi-lane models can produce up to 1600 sticks per minute, catering to large-scale commercial demand.

Designed for Industrial Use

These machines are the backbone of large food production facilities. Their design is focused on maximizing output, minimizing downtime, and integrating seamlessly into a larger automated production line.

Key Factors Beyond Lane Count

Choosing the right machine involves more than just counting lanes. Several other factors define a machine's capability and suitability for your specific operation.

Level of Automation

Semi-automatic machines require an operator to manually load the packaging film and remove the finished sticks. This is common in smaller, single-lane setups.

Fully automatic machines handle the entire process without manual intervention, from loading the film to discharging the final product. This level of automation is essential for the high speeds of multi-lane systems.

Stick and Seal Customization

A standard honey stick is typically 6-7 inches long and ¼ inch wide. However, machines can be configured for different outputs.

A twin-type machine, for example, is a specialized variant that produces two sticks connected together simultaneously.

Machines also offer various seal types, such as fin seals, lap seals, and 3- or 4-side seals, allowing for different packaging aesthetics and requirements.

Understanding the Trade-offs

Cost vs. Capacity

The primary trade-off is investment versus output. A single-lane machine has a much lower initial cost but is capped in its production capacity. A multi-lane machine is a significant capital investment that pays off through massive volume and lower per-unit production costs.

Footprint and Complexity

More lanes mean a larger, more complex machine. Single-lane models are compact and relatively simple to operate and maintain. Multi-lane systems require more floor space, skilled operators, and a more intensive maintenance schedule.

Flexibility for Batches

Single-lane machines often provide greater flexibility for running small, diverse batches of different honey flavors or product variations. Multi-lane machines are optimized for long, continuous runs of a single product to maximize their efficiency.

Selecting the Right Machine for Your Operation

- If your primary focus is launching an artisanal brand or a small business: A single-lane, semi-automatic machine provides the lowest barrier to entry and sufficient capacity.

- If your primary focus is supplying regional or national distributors: A multi-lane, fully automatic machine is necessary to meet the volume, speed, and cost-efficiency demands.

- If your primary focus is adding a novelty product to an existing line: A single-lane machine offers the flexibility to experiment with small runs without a major investment.

Ultimately, choosing the right honey stick machine is about aligning the equipment's capabilities with your specific production goals.

Summary Table:

| Machine Type | Production Lanes | Ideal Use Case | Key Characteristic |

|---|---|---|---|

| Single-Lane | 1 | Start-ups, small batches, artisanal brands | Lower cost, compact, flexible for small runs |

| Multi-Lane | 2+ | High-volume commercial production, large distributors | High speed (up to 1600 sticks/min), automated, for large-scale runs |

Ready to Scale Your Honey Stick Production?

Whether you're a start-up apiary or a large-scale distributor, choosing the right equipment is critical to your success. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the robust, high-capacity honey stick machines needed for efficient, profitable production.

Let our experts help you select the perfect single-lane or multi-lane machine to meet your specific volume and budget requirements.

Contact HONESTBEE today for a consultation and discover how our wholesale-focused solutions can power your growth!

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- How do semi-automatic filling machines operate? Boost Your Production with Hybrid Precision and Versatility

- What is the value of honey filling and packaging machinery? Accelerate Commercial Scalability and Global Market Access

- How do industrial honey filling machines contribute to the efficiency of honey export trade? Boost Global Trade ROI

- How does a semi-automatic filling machine operate? Boost Your Production Consistency

- Why has the small bag honey packaging machine been favored by manufacturers? Unlock Efficiency & Quality

- What core advantages do automated honey filling machines provide? Scaling Your Production with Precision

- What is the working principle of a honey stick machine? Master High-Precision VFFS Packaging Technology

- What is honey filling equipment used for? Optimize Your Bottling with Precision Automation