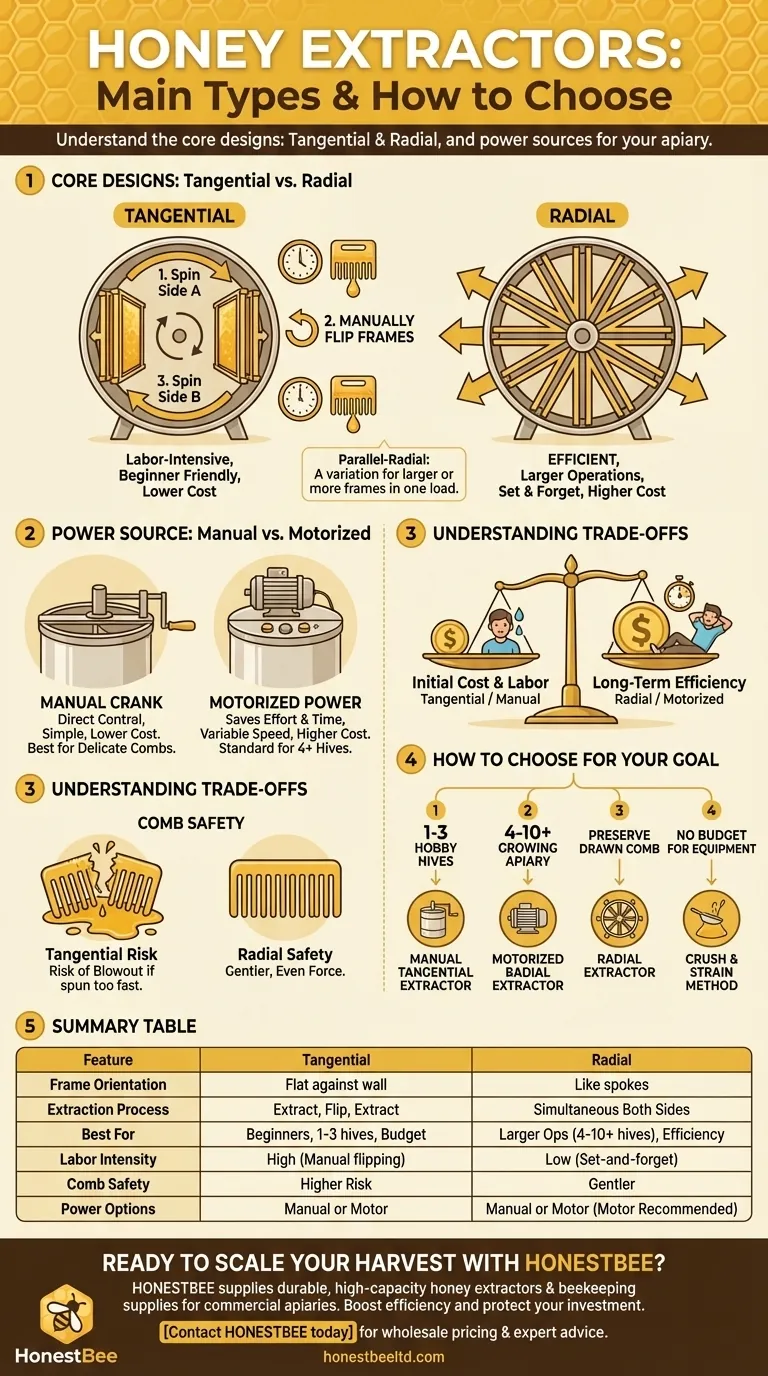

The two fundamental designs for honey extractors are tangential and radial. These core types describe how the frames are positioned inside the extractor, which directly impacts the efficiency of the process, and both can be powered either by a manual hand crank or an electric motor.

Your choice of a honey extractor ultimately boils down to a trade-off between initial cost and operational efficiency. Tangential models are affordable but labor-intensive, ideal for beginners, while radial models are faster and less hands-on, justifying their higher cost for larger operations.

The Core Designs: Tangential vs. Radial

The primary distinction between extractors is the orientation of the frames. This single factor determines the speed and labor involved in your harvest.

How Tangential Extractors Work

A tangential extractor positions the frames so they are flat against the wall of the drum, like pictures hanging on a circular wall.

Only the outer side of the honeycomb faces outward. This means you must spin the frames to extract one side, manually flip each frame, and then spin them again to extract the other side.

How Radial Extractors Work

A radial extractor positions the frames like the spokes of a wheel, with the top bar of the frame facing the outer wall.

As the extractor spins, centrifugal force pulls honey out of both sides of the comb simultaneously. This design is significantly more efficient and eliminates the need to flip frames.

A Note on Parallel-Radial Extractors

A less common variation is the parallel-radial extractor. It also positions frames like spokes but is designed specifically to accommodate larger frames or to maximize the number of smaller frames in a single load.

The Power Source: Manual vs. Motorized

Once you understand the core design, the next choice is how you will power the machine. This decision impacts cost, convenience, and where you can work.

The Simplicity of a Manual Crank

Manual extractors use a hand crank to spin the basket. They are popular with beginners due to their lower cost, simplicity, and independence from a power source.

This design gives you direct control over the extraction speed, which can be useful for delicate new comb.

The Efficiency of Motorized Power

Motorized extractors use an electric motor, saving significant physical effort and time. They are the standard for any beekeeper with more than a few hives.

Most models feature variable speed controls, allowing you to start slowly to protect the comb before ramping up for full extraction.

Understanding the Trade-offs

Choosing an extractor is about balancing your budget against your time and the scale of your beekeeping.

Initial Cost vs. Long-Term Efficiency

Tangential, manually-cranked extractors are the most affordable entry point into mechanical extraction.

Radial, motorized units represent a much larger initial investment but provide a dramatic return in saved time and labor, especially as your apiary grows.

Labor and Time Investment

The primary drawback of a tangential extractor is the labor involved. You must stop the process, open the machine, and physically flip every frame to extract both sides.

A radial extractor is a "set it and forget it" process in comparison. Once loaded, it runs until the job is complete.

Potential for Comb Damage

With a tangential extractor, the full weight of the honey on the unextracted inner side can cause the comb to "blow out" or break if you spin too fast, too soon.

Radial extractors apply a more even force to both sides of the comb, making them generally gentler on the beeswax foundation.

How to Choose the Right Extractor for Your Goal

Your choice depends entirely on the scale of your operation and your long-term beekeeping ambitions.

- If your primary focus is managing 1-3 hobby hives: A small, manual tangential extractor offers the best balance of cost and functionality.

- If you manage a growing apiary of 4-10+ hives: A motorized radial extractor is a worthwhile investment that will save you significant time and labor during harvest.

- If your primary focus is preserving your drawn comb: A radial extractor is generally gentler, especially on new or delicate comb.

- If you have no budget for equipment: The "crush and strain" method, which destroys the comb, is a viable alternative to mechanical extraction.

Understanding these core differences empowers you to select the right tool for your specific beekeeping journey.

Summary Table:

| Feature | Tangential Extractor | Radial Extractor |

|---|---|---|

| Frame Orientation | Flat against the drum wall | Like spokes of a wheel |

| Extraction Process | Extract one side, flip frames, extract other side | Extract both sides simultaneously |

| Best For | Beginners, 1-3 hives, lower budget | Larger operations (4-10+ hives), efficiency |

| Labor Intensity | High (requires manual flipping) | Low (set-and-forget) |

| Comb Safety | Higher risk of blowout if spun too fast | Gentler, more even force |

| Power Options | Manual crank or motor | Manual crank or motor (motor recommended) |

Ready to Scale Your Harvest with the Right Equipment?

As a commercial beekeeper or distributor, your time and comb integrity are critical. HONESTBEE supplies durable, high-capacity honey extractors and other essential beekeeping supplies designed for the demands of commercial apiaries. Let us help you choose the perfect radial or tangential model to boost your operation's efficiency and protect your investment.

Contact HONESTBEE today for wholesale pricing and expert advice tailored to your apiary's needs.

Visual Guide

Related Products

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What are the key steps to follow when using a honey extractor? Expert Tips for a Perfect Harvest

- What are the features of a motorized honey extractor? Boost Efficiency and Precision in Your Honey Harvest

- How do automated honey extractors reduce physical strain for beekeepers? Boost Efficiency & Prevent Burnout

- How long does an electric honey extractor take? Drastically Cut Your Harvest Time & Effort

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.