Maintaining a honey packaging machine centers on one core challenge: managing the product's unique stickiness. Effective maintenance requires a disciplined routine of frequent and thorough cleaning, made possible by machines designed with easily removable parts. This approach is essential to prevent residue buildup, which can lead to mechanical failures and product contamination.

The central takeaway is that honey packaging machine maintenance is less about periodic repair and more about a daily preventative cleaning discipline. The machine's design dictates the ease of this maintenance; therefore, selecting equipment with tool-less disassembly is the most critical factor for ensuring operational efficiency and product integrity.

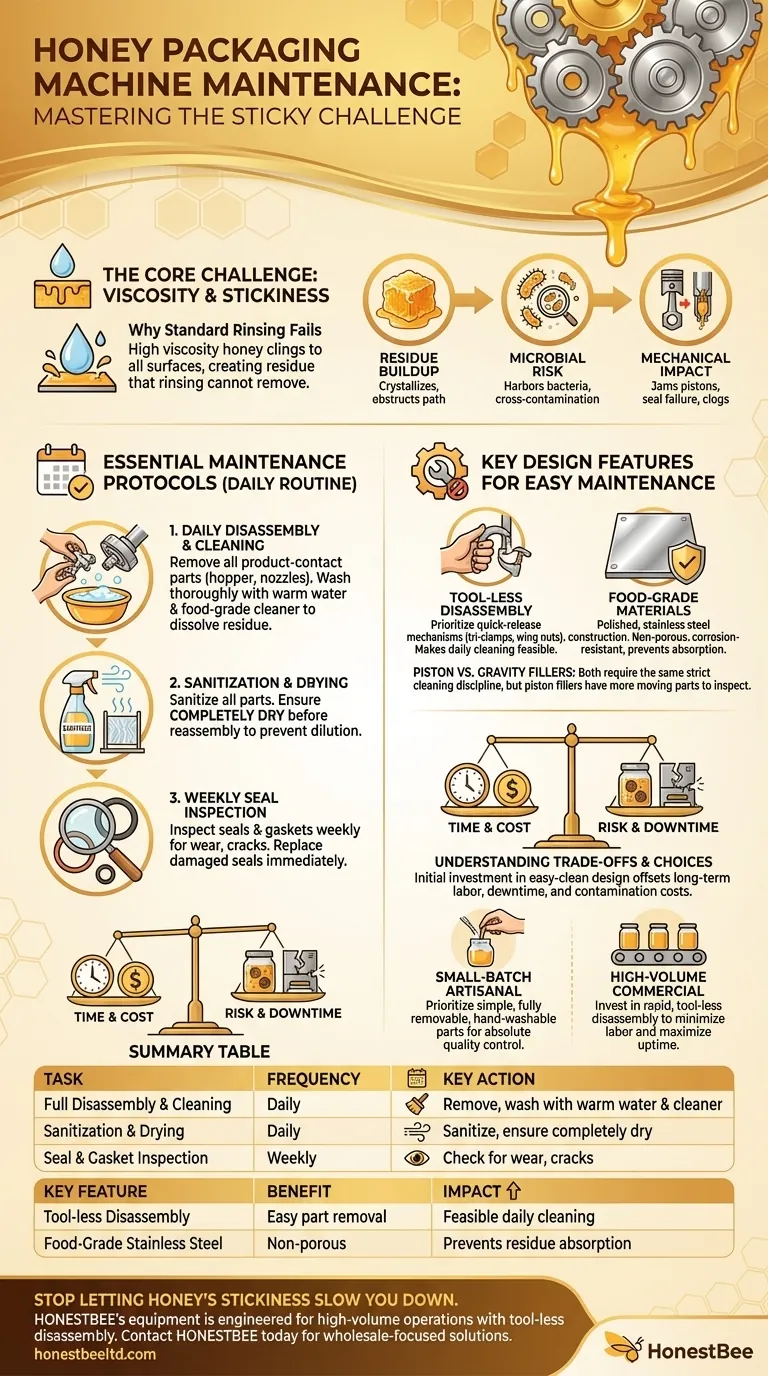

The Core Challenge: Honey's Viscosity and Stickiness

Honey's physical properties are the primary driver of all maintenance requirements. Unlike less viscous liquids, it adheres strongly to every surface it touches, creating specific operational risks if not managed properly.

Why Standard Rinsing Fails

A simple flush or rinse is insufficient for honey packaging equipment. The product's high viscosity means it clings to internal surfaces, pipes, nozzles, and pistons, leaving behind a significant film of residue.

The Risk of Residue Buildup

Leftover honey can crystallize, harden, and obstruct the product path. More importantly, this residue can harbor bacteria, leading to cross-contamination between batches and compromising the quality and safety of your product.

Impact on Mechanical Components

Sticky buildup directly impacts machine performance. It can cause pistons to jam, seals to fail, and filling nozzles to clog, resulting in inaccurate dispensing volumes, increased strain on motors, and eventual mechanical breakdown.

Essential Maintenance Protocols

A successful maintenance strategy is built on a consistent, non-negotiable daily routine. The goal is to return the machine to a pristine state after every production run.

Daily Disassembly and Cleaning

This is the most critical maintenance task. At the end of each day, all parts that come into contact with honey—such as the hopper, valves, seals, and filling nozzles—must be disassembled.

These components should be washed thoroughly with warm water and appropriate food-grade cleaning agents to dissolve all honey residue.

Sanitization and Drying

After washing, all parts must be sanitized using a food-grade sanitizer to eliminate any microbial risk. It is equally important to ensure every component is completely dry before reassembly to prevent dilution of the next batch of honey.

Regular Inspection of Seals and Gaskets

Seals and O-rings are common failure points. They should be inspected weekly for any signs of wear, cracking, or degradation. Damaged seals can lead to leaks and are difficult to clean effectively, creating a contamination risk.

Key Design Features That Simplify Maintenance

The ease and effectiveness of your maintenance routine are determined by the machine's design. When evaluating equipment, these features are paramount.

Tool-less Disassembly

Prioritize machines that allow for tool-less or minimal-tool disassembly. Components connected with tri-clamps, wing nuts, or quick-release mechanisms can be removed by hand in minutes, making daily cleaning feasible rather than a major project.

Food-Grade, Accessible Materials

The product path should be constructed from polished, food-grade stainless steel. This material is non-porous, corrosion-resistant, and easy to clean, preventing honey from seeping into the machine's surfaces.

Piston vs. Gravity Fillers

Both piston fillers (for accuracy) and gravity fillers (for simplicity) require the same cleaning discipline. However, piston fillers have more moving parts and seals (the piston head itself) that demand careful inspection and cleaning to maintain fill accuracy.

Understanding the Trade-offs

Choosing and maintaining a honey packaging machine involves balancing initial investment against long-term operational costs.

Time vs. Contamination Risk

Thorough disassembly and cleaning takes time away from production. However, cutting corners on this process directly increases the risk of product contamination and costly machine downtime, making the time investment a critical form of insurance.

Initial Cost vs. Labor Costs

Machines designed for easy cleaning often have a higher initial purchase price. This upfront cost is frequently offset by significant long-term savings in labor, reduced downtime, and prevention of lost product. A machine that is difficult to clean will incur hidden costs every single day.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your production scale and business objectives.

- If your primary focus is small-batch, artisanal production: Prioritize a simple tabletop piston or gravity filler with completely removable and hand-washable parts to ensure absolute quality control.

- If your primary focus is high-volume commercial production: Invest in a machine engineered for rapid, tool-less disassembly to minimize the labor time required for daily cleaning and maximize operational uptime.

Ultimately, effective maintenance for honey packaging equipment begins with selecting a machine designed from the ground up for effortless and thorough cleaning.

Summary Table:

| Maintenance Task | Frequency | Key Action |

|---|---|---|

| Full Disassembly & Cleaning | Daily | Remove all product-contact parts; wash with warm water and food-grade cleaner. |

| Sanitization & Drying | Daily | Sanitize parts; ensure they are completely dry before reassembly. |

| Seal & Gasket Inspection | Weekly | Check for wear, cracks, or degradation to prevent leaks. |

| Key Design Feature | Benefit | Impact on Maintenance |

| Tool-less Disassembly | Easy part removal | Makes daily cleaning feasible and quick. |

| Food-Grade Stainless Steel | Non-porous, corrosion-resistant | Prevents residue absorption; easy to clean. |

Stop letting honey's stickiness slow you down. For commercial apiaries and distributors, consistent machine uptime is critical. HONESTBEE's honey packaging equipment is engineered for high-volume operations, featuring tool-less disassembly for rapid daily cleaning. This minimizes labor time, prevents costly contamination, and protects your product quality. Let us help you select the right machine for your scale. Contact HONESTBEE today for a consultation on our wholesale-focused packaging solutions.

Visual Guide

Related Products

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Manual Honey Filling Machine Bottling Machine for Honey

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

People Also Ask

- Why is professional honey filling machinery critical for honey production? Scale Your Apiary's Profit & Efficiency

- What are the main processes of a sachet filling and packing machine? Streamline Your Packaging Line

- How do honey filtration and automated filling equipment contribute to commercial value? Boost Your Brand & ROI

- Why are professional-grade honey filling machines necessary? Boost Accuracy and Hygiene in Commercial Production

- Why is precision honey filling equipment critical for competitiveness? Secure Market Authority with Advanced Packaging

- How does a piston filling machine operate? Master Volumetric Precision for High-Viscosity Products

- How do automated honey filling machines contribute to the commercial competitiveness of honey products? Master Your Market

- How does the filling mechanism differ between gravity and piston filling machines? Choose the Right Filler for Your Product