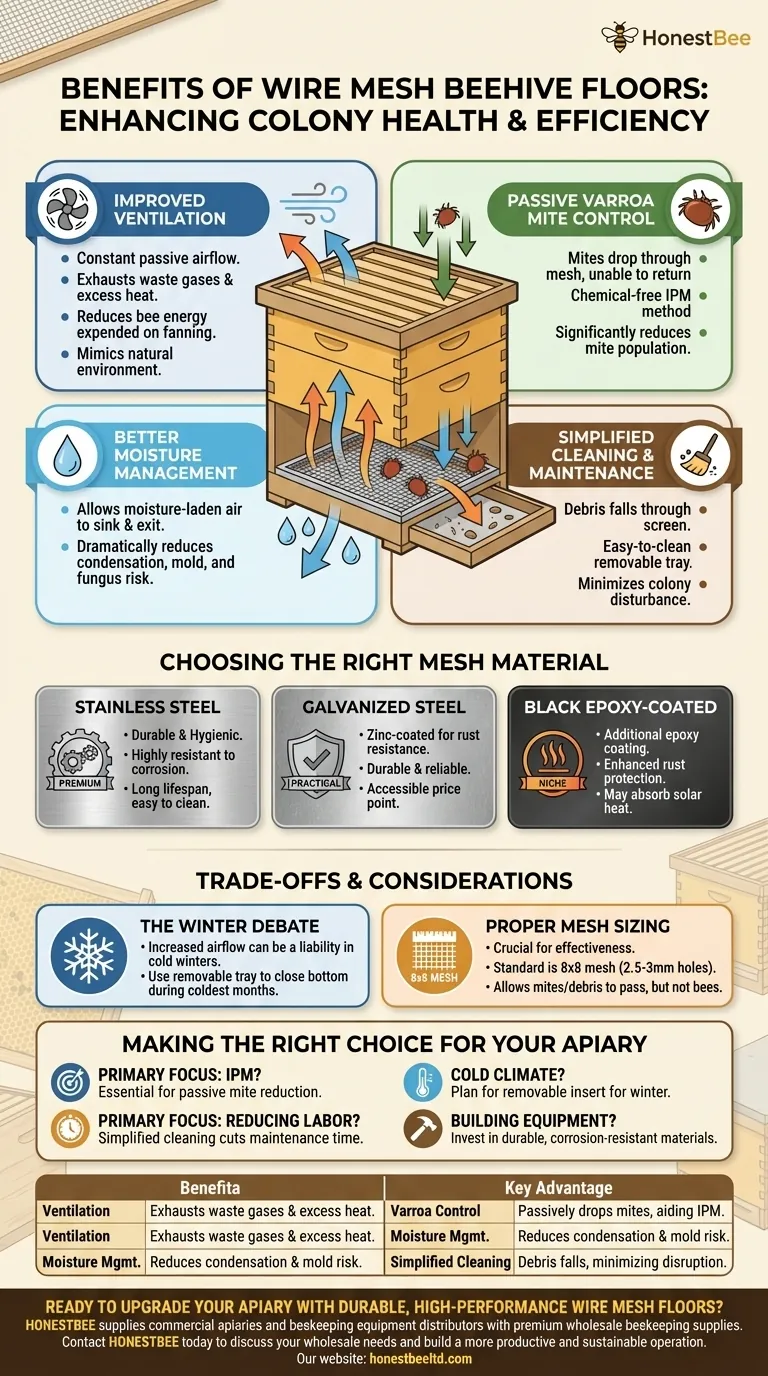

The primary benefits of a wire mesh beehive floor are improved hive ventilation, passive control of Varroa mites, simplified cleaning, and better moisture management. By replacing a traditional solid floor with a screened bottom board, you create a healthier internal environment that helps regulate temperature and humidity while allowing pests and debris to fall out of the hive.

A wire mesh floor transforms the hive from a simple box into a more dynamic, self-regulating ecosystem. This single component is one of the most effective upgrades a beekeeper can make to improve colony health and reduce their own maintenance workload.

The Core Functions of a Wire Mesh Floor

A screened bottom board is not just a floor; it's an active environmental management tool. Its benefits stem from fundamentally changing the airflow and waste disposal within the hive.

Enhancing Hive Ventilation

A wire mesh floor provides constant, passive ventilation. This upward draft helps exhaust waste gases like carbon dioxide and removes excess heat during hot summer months, reducing the energy bees must expend on fanning.

This continuous airflow mimics a more natural hive environment, reducing stress on the colony.

Managing Moisture and Condensation

Moisture is a significant threat to a honeybee colony, especially in winter. Warm, moist air from the bees' respiration rises, hits the cold inner cover, and condenses into water droplets that can drip down and chill or kill the bees.

A mesh floor allows this heavy, moisture-laden air to sink and exit the hive, dramatically reducing the risk of condensation and the growth of mold or fungus.

A Critical Tool for Varroa Mite Control

The Varroa destructor mite is a primary pest for honeybees. As mites move around the hive or fall off their bee hosts, a solid floor allows them to simply climb back onto another bee.

A wire mesh floor breaks this cycle. When mites fall, they drop completely through the mesh and out of the hive, unable to return. This provides a constant, chemical-free method of reducing the mite population, a key principle of Integrated Pest Management (IPM).

Streamlining Hive Maintenance

Cleaning a solid bottom board requires disassembling the hive and scraping away accumulated debris and dead bees. This is labor-intensive and highly disruptive to the colony.

With a mesh floor, debris falls through the screen. Most screened bottom boards also include a removable tray or "sticky board" that slides in underneath. The beekeeper can simply slide this tray out, clean it, and slide it back in with minimal disturbance to the bees.

Choosing the Right Mesh Material

The longevity and effectiveness of your screened bottom board depend heavily on the material you choose.

Stainless Steel: The Premium Standard

Stainless steel is the top choice for durability and hygiene. It is highly resistant to corrosion and rust, will not degrade over time, and is exceptionally easy to clean. While the initial cost is higher, its long lifespan makes it a cost-effective investment.

Galvanized Steel: The Practical Workhorse

Galvanized steel wire mesh is coated with zinc to provide excellent rust resistance. It is a durable and reliable option that offers many of the benefits of stainless steel at a more accessible price point, making it a popular and practical choice for most beekeepers.

Black Epoxy-Coated: A Niche Application

This type of mesh has an additional epoxy coating for enhanced rust protection. The black color may also absorb more solar heat, which can be a minor benefit in cooler climates. However, its primary advantage is its corrosion resistance.

Understanding the Trade-offs and Considerations

While highly beneficial, a wire mesh floor introduces new management considerations that every beekeeper must understand.

The Winter Debate: To Close or Not to Close?

The increased airflow that is beneficial in summer can become a liability in cold winters, potentially creating a draft that makes it harder for the colony to maintain its cluster temperature.

For this reason, most beekeepers in climates with harsh winters use the removable slide-in tray to close off the bottom of the hive during the coldest months. This blocks the draft while still allowing the beekeeper to perform periodic "mite drop" counts on the board.

Proper Mesh Sizing is Crucial

The mesh openings must be sized correctly. The industry standard is an 8x8 mesh, which creates holes around 2.5mm to 3mm wide.

This size is large enough for Varroa mites and debris to fall through but small enough to prevent bees from passing through or getting stuck. Using the wrong size can render the floor ineffective or even dangerous for your bees.

Making the Right Choice for Your Apiary

Use your primary beekeeping goals to determine how to best leverage a wire mesh floor.

- If your primary focus is Integrated Pest Management (IPM): A mesh floor is essential for passively reducing Varroa populations and for performing accurate mite drop counts on a slide-in board.

- If your primary focus is reducing beekeeper labor: The simplified cleaning and hive monitoring enabled by a screened bottom board will significantly cut down on your maintenance time and hive disruption.

- If you are in a climate with cold winters: Plan to use a screened bottom board with a removable insert that allows you to close off the ventilation during the coldest periods.

- If you are building your own equipment: Invest in durable, corrosion-resistant materials like stainless or galvanized steel to ensure your equipment lasts for many seasons.

Ultimately, integrating a wire mesh floor is a foundational step toward a more proactive and sustainable beekeeping practice.

Summary Table:

| Benefit | Key Advantage |

|---|---|

| Ventilation | Exhausts waste gases and excess heat, reducing bee stress. |

| Varroa Mite Control | Passively drops mites from the hive, aiding IPM. |

| Moisture Management | Reduces condensation and mold risk by allowing moist air to escape. |

| Simplified Cleaning | Debris falls through the mesh, minimizing hive disruption during maintenance. |

Ready to upgrade your apiary with durable, high-performance wire mesh floors?

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with premium wholesale beekeeping supplies. Our wire mesh floors are crafted from durable materials like stainless steel and galvanized steel to ensure long-lasting performance and support your colony health goals.

Contact HONESTBEE today to discuss your wholesale needs and discover how our equipment can help you build a more productive and sustainable operation.

Visual Guide

Related Products

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

- Solid Bottom Board Australian Pine Wood Langstroth Bottom Board for Wholesale

- HONESTBEE Wooden Bee Escape Board with Triangle Mesh Design for Beekeeping

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

People Also Ask

- What are the disadvantages of using a screened bottom board on a beehive? Risks and Management Tips

- What are the assembly options for the Cypress Screened Bottom Board? Ready-to-Use for Immediate Hive Health

- What is the function of screened bottom boards in IPM for beekeeping? Boost Hive Health and Pest Control

- What is a screened bottom board for a beehive? Boost Hive Health with Better Ventilation and Mite Control

- What are the benefits of using screened bottom boards? Improve Hive Health & Control Varroa Mites