At its core, a honey extractor's size is defined by the number of frames it can hold, ranging from small 2-frame models to commercial units holding over 60. Its power source is either a manual hand-crank or an electric motor. Smaller capacity extractors are typically manual, while larger ones are almost always electric to handle the increased weight and scale.

The choice between extractor sizes and power sources is not just a technical detail—it's a strategic decision that directly impacts the efficiency, cost, and labor required for your entire honey harvesting process. Understanding the trade-offs is key to matching the equipment to the scale of your beekeeping.

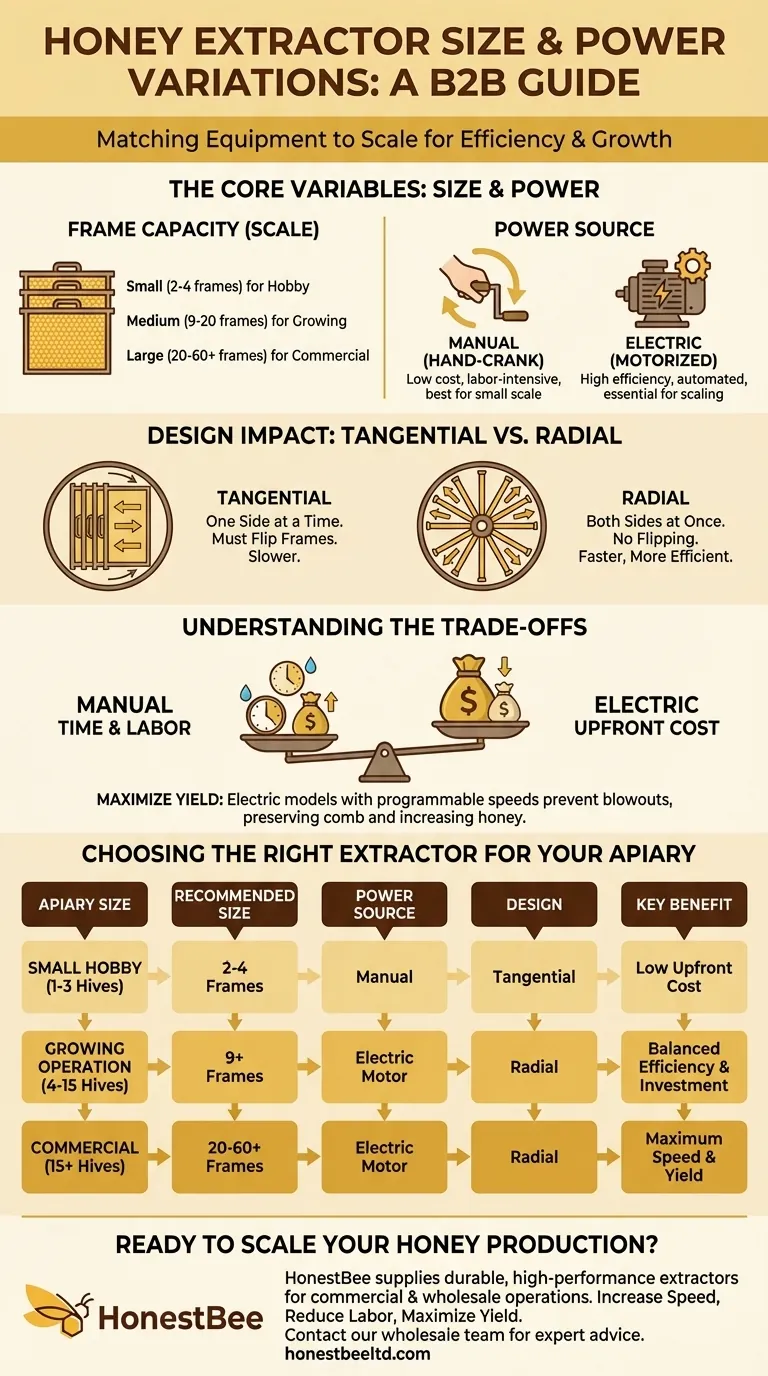

The Core Variables: Size and Power

The two most fundamental characteristics of any honey extractor are its capacity and its power source. These factors work together to define its suitability for a given beekeeping operation.

Frame Capacity (Scale)

An extractor's size is measured by the number of frames it can spin at once. This ranges from small, 2-to-4-frame units ideal for hobbyists with a few hives.

Larger operations use extractors that can hold anywhere from 9 to 60 or more frames. The capacity you need is a direct function of the number of hives you manage.

Manual (Hand-Crank) Power

Manual extractors use a hand-crank connected to a gearing system to spin the internal basket. This system allows you to achieve high rotational speeds with reasonable physical effort.

These models are the most affordable and are popular among beginner beekeepers. However, they are labor-intensive and require significant time and effort, especially with more than a few hives.

Electric (Motorized) Power

Electric extractors use a motor to provide consistent, powerful, and quiet rotation. This automates the most physically demanding part of honey extraction.

While more expensive, motorized units are far more efficient, spinning up quickly and extracting honey faster. They are the standard for any beekeeper looking to scale beyond a small hobby.

Beyond Power: The Impact of Extractor Design

The way an extractor holds the frames—its design—is just as important as its power source. This primarily comes down to two types: tangential and radial.

Tangential Extractors

In a tangential extractor, the frames are placed with one side of the honeycomb facing the outer wall of the drum. Centrifugal force extracts honey from that outer-facing side only.

This means you must stop the process, flip each frame by hand, and then spin again to extract from the second side. This design is common in smaller, manual extractors due to its simplicity.

Radial Extractors

In a radial extractor, frames are positioned vertically like the spokes of a wheel, with the top bar of the frame facing outwards.

As the basket spins, centrifugal force pulls honey from both sides of the comb simultaneously. This design is significantly more efficient and is the standard for larger, motorized extractors.

Understanding the Trade-offs

Choosing an extractor involves balancing cost, time, and labor. There is no single "best" option, only the one that is right for your goals.

Cost vs. Efficiency

A manual extractor has a low upfront cost but a high cost in time and labor. It is a practical entry point but quickly becomes a bottleneck as your apiary grows.

An electric extractor is a significant investment but pays for itself in saved labor and increased speed. It streamlines harvesting, allowing you to process more honey in less time.

Labor vs. Automation

The physical effort required to crank a manual extractor for hours can be substantial. This is a hands-on approach that some enjoy, but it can be physically limiting.

Automation via an electric motor removes this strain, freeing you to perform other tasks like uncapping the next batch of frames. This makes the entire workflow faster and more consistent.

Maximizing Yield and Quality

Electric extractors with programmable speeds can start slowly and ramp up, which helps prevent "blowouts" where the weight of the honey breaks the delicate wax comb. This preserves your comb for the bees to use again.

The consistent and powerful spin also ensures a more complete extraction, maximizing your honey yield from each frame.

How to Choose the Right Extractor for Your Apiary

Your choice should be guided by the current size and future goals of your apiary.

- If your primary focus is a small hobby (1-3 hives): A small, 2-to-4-frame manual tangential extractor is the most cost-effective and practical choice.

- If your primary focus is a growing operation (4-15 hives): An electric radial extractor offers the best balance of efficiency and investment to save significant time and labor.

- If your primary focus is commercial production (15+ hives): A large, high-capacity motorized radial extractor is an essential tool for managing workflow and maximizing production.

Selecting the right extractor transforms harvesting from a laborious chore into an efficient and rewarding part of your beekeeping journey.

Summary Table:

| Feature | Small Hobby (1-3 Hives) | Growing Operation (4-15 Hives) | Commercial (15+ Hives) |

|---|---|---|---|

| Recommended Size | 2-4 frames | 9+ frames | 20-60+ frames |

| Power Source | Manual (Hand-Crank) | Electric Motor | Electric Motor |

| Design | Tangential | Radial | Radial |

| Key Benefit | Low upfront cost | Balanced efficiency & investment | Maximum speed & yield |

Ready to Scale Your Honey Production?

As a commercial beekeeper or equipment distributor, choosing the right extractor is critical to your profitability. HONESTBEE supplies durable, high-performance honey extractors and beekeeping equipment designed specifically for the demands of commercial apiaries and wholesale operations.

We help you:

- Increase Harvesting Speed with reliable electric radial extractors.

- Reduce Labor Costs by automating the most physically demanding tasks.

- Maximize Honey Yield with equipment that preserves comb integrity.

Let’s discuss the best extractor for your scale and goals. Contact our wholesale team today for expert advice and pricing.

Visual Guide

Related Products

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- HONESTBEE 6 Frame Three Use Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

People Also Ask

- What roles do high-precision timers and weighing balances play in the performance evaluation of a Honey Extractor?

- What is the primary function of a DC motor in a self-reversing honey extractor? Master Precision Honey Extraction

- What are the advantages of portable honey extraction for stingless bees? Elevate Purity & Hive Health

- What are the nutritional advantages of using mechanized honey extraction equipment? Boost Purity & Enzyme Preservation

- What should be considered when using a honey extractor to avoid damage? Ensure a Smooth, Efficient Harvest

- What roles do centrifuges and multi-stage filtration equipment play in honey extraction? Expert Analysis

- How does the scale of a beekeeping operation influence the choice of a honey extractor? Scaling for Success

- What is the value of using an electric honey extractor? Scale Your Apiary with Effortless Extraction