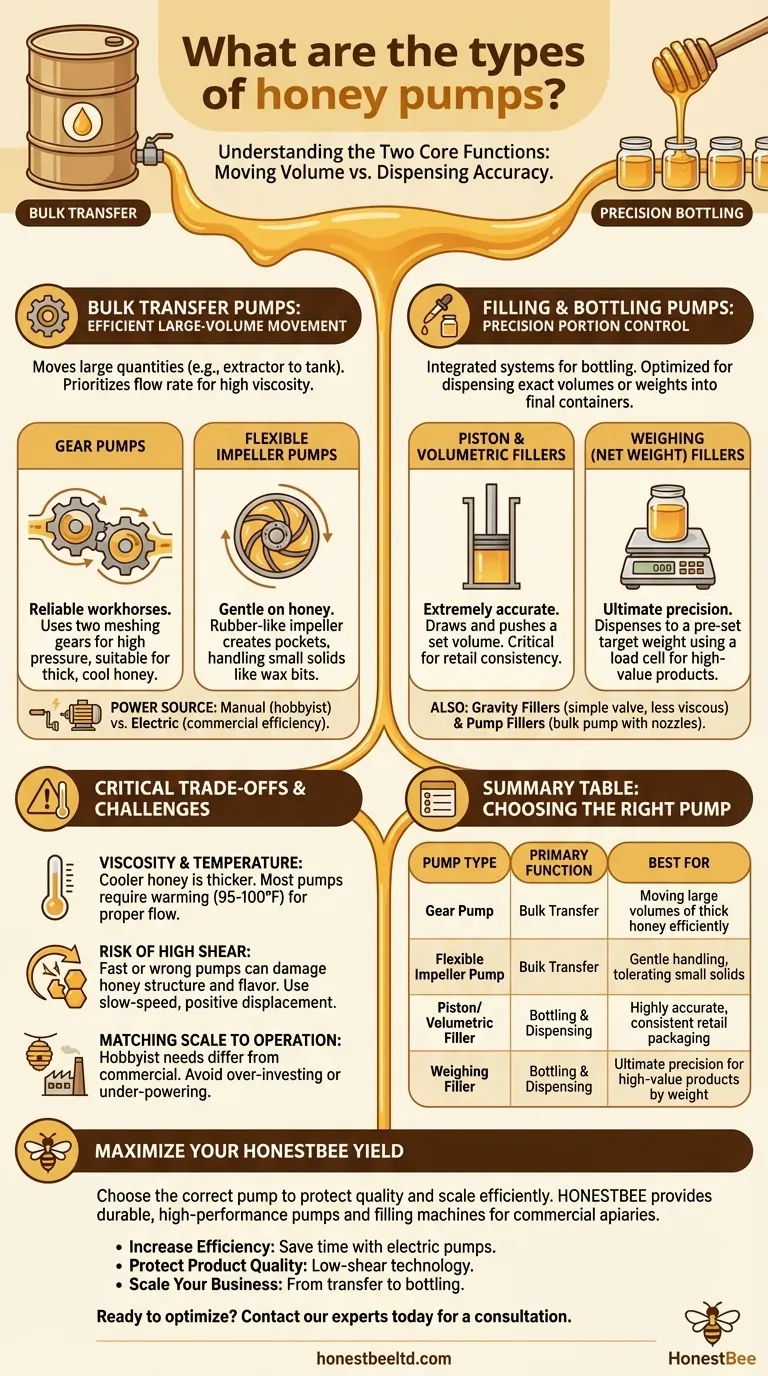

At its core, a honey pump is a device designed to move highly viscous honey from one point to another. The term is commonly used to describe two distinct categories of equipment: bulk transfer pumps for moving large volumes of honey, and the precision mechanisms inside honey filling machines used for bottling.

The most critical distinction is not manual versus electric, but the pump’s intended function. Your choice depends entirely on whether your goal is to transfer honey in bulk or to dispense it into final containers.

The Two Meanings of "Honey Pump"

The term "honey pump" creates frequent confusion because it is used for two very different tasks in honey processing. Understanding this distinction is the first step to selecting the right equipment.

Bulk Transfer Pumps: Moving Honey Efficiently

This is the most literal definition of a honey pump. Its sole purpose is to move large quantities of honey, such as from an extractor to a settling tank or from a large drum into a bottling machine's hopper. These pumps prioritize flow rate and are built to handle high viscosity.

Filling & Bottling Pumps: Dispensing with Precision

These "pumps" are actually integrated systems or machines designed for bottling. The pumping mechanism inside them is optimized for accuracy, dispensing a precise volume or weight of honey into jars. While they do pump honey, their primary goal is portion control, not bulk transfer.

Core Types of Bulk Transfer Pumps

For moving honey between tanks and vessels, positive displacement pumps are the industry standard. They move fluid in discrete, trapped volumes, making them ideal for thick liquids without causing damage.

Gear Pumps

Gear pumps are the workhorses of honey transfer. They use two meshing gears to pull honey into the pump and push it out the other side. They are reliable, can run at slow speeds to protect the honey, and generate the pressure needed to move thick, cool honey.

Flexible Impeller Pumps

These pumps use a rubber-like, flexible impeller with vanes that bend to create pockets of fluid. As the impeller rotates, it traps honey and forces it through the outlet. They are gentle on the honey and can handle some small solids, like bits of wax.

Power Source: Manual vs. Electric

Both gear and impeller pumps can be powered manually or by an electric motor. A manual pump is operated by a hand crank and is suitable for hobbyists moving small quantities. An electric pump offers significant time and labor savings, making it essential for any commercial or serious sideline operation.

Core Types of Honey Filling Machines

When the goal is bottling, you are looking for a filling machine, which contains its own specialized pumping system.

Piston & Volumetric Fillers

These are the most common for honey. A piston pulls back to draw a set volume of honey into a cylinder, then pushes forward to dispense that exact volume into a container. They are extremely accurate and consistent, which is critical for retail packaging.

Weighing Fillers

Also known as "net weight fillers," these machines dispense honey until the container reaches a pre-set target weight. They use a scale (load cell) to ensure precision, which is ideal for high-value products where accuracy is paramount.

Gravity & Pump Fillers

Gravity fillers use a simple valve system, letting honey flow from an overhead tank into bottles. They work best for less viscous (i.e., warmer) honey. Pump fillers are similar but use a bulk transfer pump (like a gear pump) to feed a series of filling nozzles, offering more control than gravity alone.

Understanding the Critical Trade-offs

Choosing the wrong pump can waste time, money, and even damage the quality of your honey.

The Challenge of Viscosity & Temperature

Honey's thickness, or viscosity, is its single most defining characteristic for pumping. Cooler honey is exponentially thicker and harder to pump. Most pumps require the honey to be warmed to at least 95-100°F (35-38°C) to flow properly.

The Risk of High Shear

Shear refers to the stress placed on a fluid as it moves. Pumps that move too fast or use the wrong mechanism, like common centrifugal pumps, can "shear" the honey. This can damage its delicate structure, introduce air, and potentially alter its flavor and texture. Slow-speed, positive displacement pumps are used to prevent this.

Matching Scale to Your Operation

A hobbyist with three hives has vastly different needs than a commercial apiary. Over-investing in a powerful electric pump for a small operation is inefficient, while trying to use a manual pump for hundreds of gallons is unsustainable.

Making the Right Choice for Your Operation

Select your equipment based on your specific stage in the honey production journey.

- If your primary focus is moving small batches as a hobbyist: A simple manual pump or even the gravity-fed "gate" on your tank is often sufficient.

- If your primary focus is transferring honey from your extractor to holding tanks: An electric, slow-speed gear pump or flexible impeller pump is your ideal solution.

- If your primary focus is bottling honey accurately for sale: You need to invest in a dedicated filling machine, most likely a piston filler or a weigh filler.

Ultimately, identifying your specific task—transfer or bottling—will guide you directly to the correct type of pump.

Summary Table:

| Pump Type | Primary Function | Best For |

|---|---|---|

| Gear Pump | Bulk Transfer | Moving large volumes of thick honey efficiently |

| Flexible Impeller Pump | Bulk Transfer | Gentle handling of honey, can tolerate small solids |

| Piston/Volumetric Filler | Bottling & Dispensing | Highly accurate, consistent filling for retail packaging |

| Weighing Filler | Bottling & Dispensing | Ultimate precision for high-value products by weight |

Maximize Your Honey Yield with the Right Equipment

Choosing the correct pump is critical for protecting your honey's quality and scaling your operation efficiently. As a leading wholesale supplier to commercial apiaries and distributors, HONESTBEE provides durable, high-performance honey pumps and filling machines designed for demanding use.

We help you:

- Increase Efficiency: Save time and labor with electric pumps built for high-volume transfer.

- Protect Product Quality: Utilize low-shear pump technology to preserve honey's delicate flavor and texture.

- Scale Your Business: Find the perfect equipment match, from bulk transfer to precision bottling.

Ready to optimize your honey processing? Contact our experts today for a personalized consultation on the best pumps for your apiary's needs.

Visual Guide

Related Products

- Honey Convey Pump Screw Honey Pump for Viscous Liquid

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

People Also Ask

- What is the function of the automatic honey suction hose? Boost Stingless Bee Honey Purity and Colony Health

- How does portable honey suction equipment function? Non-Invasive Extraction for Heterotrigona itama

- What is the best use case for pump filling machines? Efficiently Bottle Medium-Viscosity Liquids

- What is the primary role of the Honey Suction Pump? Boost Efficiency in Stingless Bee Honey Harvesting

- How does a stainless steel screw honey pump work? Efficient, Food-Grade Transfer Solutions for Your Apiary

- How do an industrial honey pump and internal screens collaborate to improve dehydration? Maximize Drying Efficiency

- What are the primary hardware components that constitute a portable electric honey suction machine? Optimize Your Harvest

- Which pump is used in a liquid filling machine? The Key to Accurate & Gentle Filling