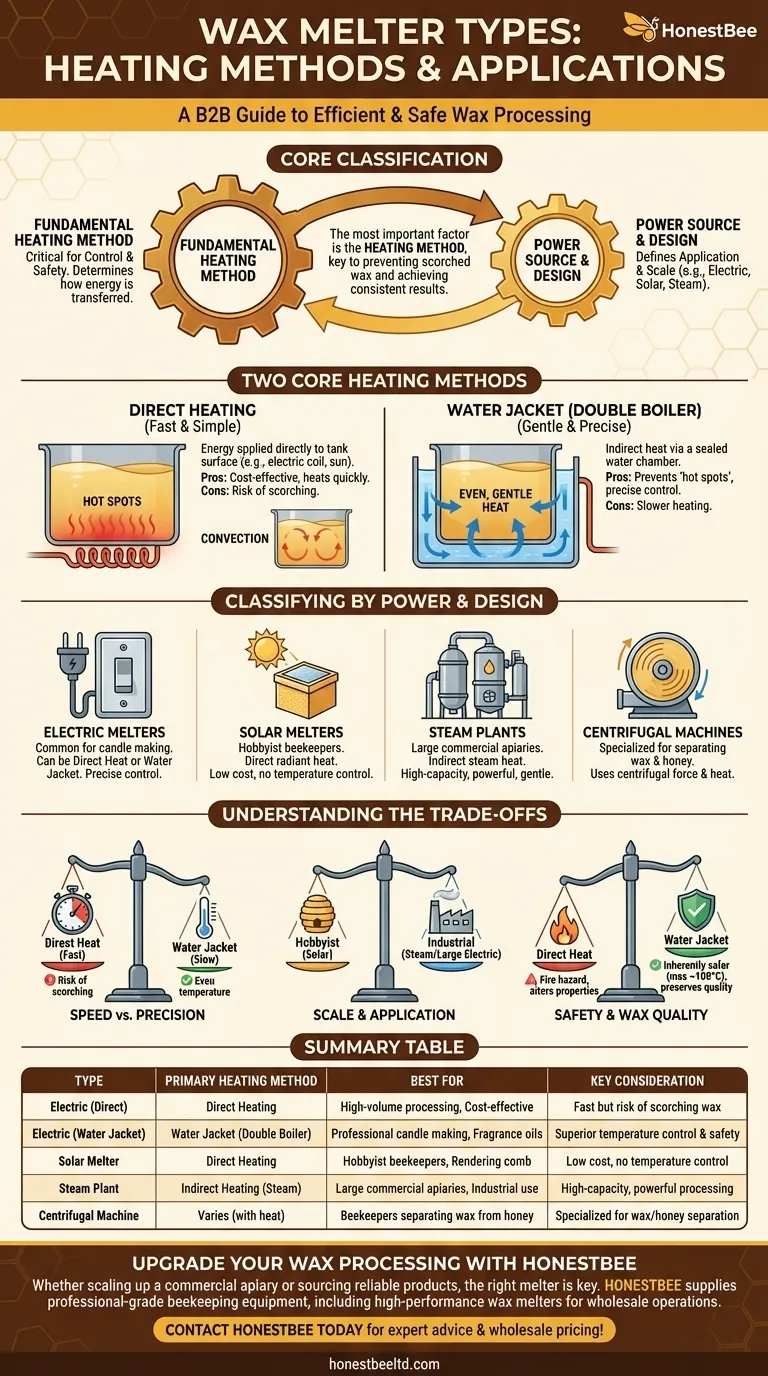

At its core, a wax melter can be classified in two primary ways: by its fundamental heating method or by its power source and design. The heating method—either direct heat or a water jacket—is the most critical distinction, as it dictates temperature control and safety. The power source, such as electric, solar, or steam, defines its application, from small-scale candle making to large-scale industrial processing.

The most important factor when choosing a wax melter is not its power source, but its heating method. Understanding the difference between direct heating and water jacket systems is the key to preventing scorched wax, ensuring safety, and achieving consistent results.

The Two Core Heating Methods

The engineering behind how a melter transfers energy to the wax is the most significant factor influencing its performance. Every melter, regardless of its power source, uses one of these fundamental principles.

Direct Heating Melters

Direct heating is the simplest method. The heating element, whether it's an electric coil or the radiant energy of the sun, applies energy directly to the surface of the tank holding the wax.

This design is common in many entry-level or high-capacity units because it is cost-effective and heats up very quickly.

Water Jacket (Double Boiler) Melters

A water jacket melter, also known as a double boiler, uses a more gentle, indirect heating method. The wax tank is surrounded by a separate, sealed chamber of water.

An element heats the water, and the hot water then evenly and gently heats the wax tank. This prevents "hot spots" where the wax could burn.

Convection Melters

Convection is a variation of direct heating often used in larger industrial units. Instead of a heating element touching the tank, heated air is circulated around the wax container.

This provides more even heating than a simple direct-contact element but is less precise than a water jacket.

Classifying Melters by Power Source & Design

While the heating method is the core principle, the power source and overall design determine where and how the melter can be used. These categories often overlap with the heating methods described above.

Electric Melters

This is the most common category for candle making and general crafting. Electric melters can be either direct heat or water jacket designs.

Their main advantage is precise temperature control, especially in water jacket models, which is crucial for working with different types of waxes and adding fragrances.

Solar Melters

A solar melter is almost exclusively used by beekeepers to render wax from old honeycomb. It's a simple insulated box with a dark interior and a glass lid, using the sun's radiant energy for direct heating.

This is a low-cost, low-energy solution perfect for processing raw comb outdoors but offers no temperature control.

Steam Plants

Steam plants are high-capacity systems for large commercial apiaries or industrial applications. Steam is piped into a jacket or coil to heat a large vat of wax.

This is a form of indirect heating, providing powerful but relatively gentle heat for processing hundreds of pounds of wax at once.

Centrifugal Machines

This is a highly specialized device, primarily for beekeepers, that separates wax from honey and impurities. It uses centrifugal force to spin the contents while heat, often from steam or electricity, melts the wax.

Understanding the Trade-offs

Choosing the right melter requires balancing speed, control, and safety based on your specific application.

Temperature Control vs. Speed

The central trade-off is precision versus speed. Direct heat melters are fast but create hot spots that can easily scorch or discolor wax, ruining its quality and scent throw.

Water jacket melters are slower to heat up, but they provide exceptionally even and precise temperature control, which is non-negotiable for professional candle making.

Scale and Application

Your intended use dictates the appropriate design. A solar melter is perfect for a hobbyist beekeeper but completely impractical for a candle business.

Conversely, a small electric water jacket melter is ideal for crafting but would be inefficient for processing the large volume of raw cappings from a commercial beekeeping operation.

Safety and Wax Quality

Overheating wax is a significant fire hazard. Direct heat melters, especially without a thermostat, pose a greater risk.

Water jacket melters are inherently safer because the water bath prevents the wax temperature from rising much beyond the boiling point of water (212°F / 100°C), well below the flashpoint of most waxes. This gentle heat also preserves the wax's natural color and properties.

Making the Right Choice for Your Goal

Select a melter based on the precision, volume, and safety your project demands.

- If your primary focus is professional candle making or cosmetics: A thermostatically controlled electric water jacket melter is the only professional choice for its precise temperature control and safety.

- If your primary focus is rendering raw honeycomb as a hobbyist beekeeper: A solar melter is the most cost-effective and simple solution for cleaning wax.

- If your primary focus is high-volume industrial or commercial wax processing: A large direct-heat convection unit or a steam plant provides the necessary throughput and power.

Ultimately, matching the heating technology to your specific goal is the key to working with wax safely and effectively.

Summary Table:

| Type | Primary Heating Method | Best For | Key Consideration |

|---|---|---|---|

| Electric (Direct Heat) | Direct Heating | High-volume processing, Cost-effectiveness | Fast but risk of scorching wax |

| Electric (Water Jacket) | Water Jacket (Double Boiler) | Professional candle making, Fragrance oils | Superior temperature control & safety |

| Solar Melter | Direct Heating | Hobbyist beekeepers, Rendering comb | Low cost, no temperature control |

| Steam Plant | Indirect Heating (Steam) | Large commercial apiaries, Industrial use | High-capacity, powerful processing |

| Centrifugal Machine | Varies (with heat) | Beekeepers separating wax from honey | Specialized for wax/honey separation |

Upgrade Your Wax Processing with HONESTBEE

Whether you're a commercial apiary scaling up operations or a beekeeping equipment distributor sourcing reliable products, the right wax melter is key to your efficiency and product quality. HONESTBEE supplies a full range of professional-grade beekeeping supplies and equipment, including high-performance wax melters designed for demanding, wholesale-focused operations.

Let us help you select the perfect equipment to improve your yield and safety. Contact HONESTBEE today for expert advice and wholesale pricing!

Visual Guide

Related Products

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- How does specialized beeswax processing equipment contribute to the efficiency and value of beekeeping operations?

- What is the primary function of solar or steam wax melters in the initial processing of raw beeswax? Maximize Wax Purity

- What is the primary function and advantage of a solar wax melter? Produce Premium, High-Purity Beeswax Naturally

- What are the advantages of integrated electric heating tubes compared to traditional steam heating? Boost Your Efficiency

- How do industrial steam wax melters and mechanical wax pressers work together to improve wax recovery? Maximize Yield