The leftover wax from your honey extraction, known as cappings, is far from a waste product. This mixture of pure beeswax and residual honey is a valuable resource that can be cleaned and rendered for a variety of uses, both within the apiary and for creating high-value household products.

Your core challenge is not what to do with the wax, but how to first separate it from the residual honey. Once cleaned, this beeswax becomes a versatile material you can use to coat hive equipment, create new foundations, or craft into premium products like candles and cosmetics.

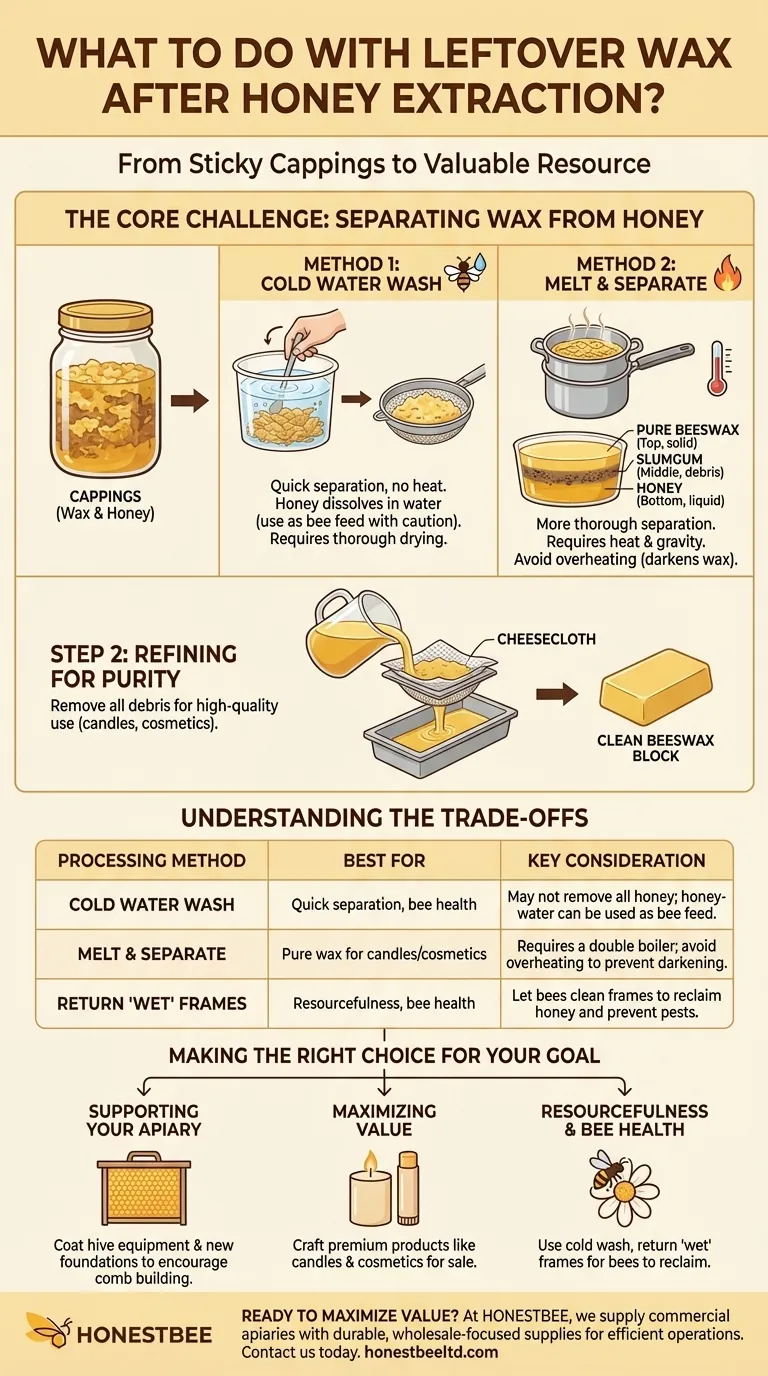

The First Step: Separating Wax from Honey

Before you can use the beeswax, you must reclaim it from the sticky, honey-laden cappings collected during extraction. There are two primary methods for this initial separation.

Method 1: The Cold Water Wash

This is a straightforward technique that avoids heating the wax. Simply place your wax cappings in a container and cover them with cold water.

Gently agitate the mixture to dissolve the honey into the water. The wax itself will not dissolve. Once the honey is washed off, strain the water and spread the wax out to dry completely.

Method 2: The Melt and Separate Technique

For a more thorough separation, you can use heat and gravity. Gently melt the cappings in a double boiler to avoid scorching the wax or honey.

Once fully melted, pour the liquid into a container and allow it to cool slowly. The mixture will naturally separate into three distinct layers: pure beeswax will float and harden on top, the heavier honey will sink to the bottom, and a layer of impurities (often called slumgum) will form in the middle.

Refining Your Beeswax for Purity

After the initial separation, your wax likely still contains small debris. A final filtering step is necessary to produce a clean, usable block of beeswax.

Why Filtering is Crucial

The "slumgum" layer from the melt method and other hive debris must be removed to achieve pure wax. This step is especially critical if you plan to use the wax for cosmetics or high-quality candles.

The Straining Process

The most common method is to re-melt the separated wax and carefully strain it through a fine filter, such as several layers of cheesecloth. This will catch any remaining physical impurities.

Creating Usable Blocks

After filtering, pour the hot, liquid wax into molds. Silicone baking molds, small loaf pans, or even simple plastic containers work well. Once cooled, these solid bricks of beeswax are easy to store and use for future projects.

Understanding the Trade-offs

Your approach to processing depends on your equipment, time, and end goals.

Cold Wash vs. Melting

The cold water wash is simple and requires no special equipment, but it may not remove all the honey. The resulting honey-water can be used as a bee feed, but use caution to prevent spreading potential diseases between hives.

The melt-and-separate method is more effective at producing pure wax and separating honey, but it requires a double boiler and more careful attention. Overheating can darken the wax and damage the honey.

Don't Forget "Wet" Frames

The frames you just extracted honey from are called "wet" frames and still contain a film of honey. Placing these frames back in a strong hive for a short period allows the bees to clean them completely, preserving valuable resources and preventing pests.

Proper Storage Before Processing

If you can't process your cappings immediately, you can store them. Place the cappings in an airtight container and keep them in a cool, dark place to protect them from pests and preserve their quality until you are ready.

Making the Right Choice for Your Goal

The best use for your beeswax depends entirely on your primary objective as a beekeeper.

- If your primary focus is supporting your apiary: Use the rendered wax to coat new plastic foundation or frames, which encourages bees to draw out comb more quickly.

- If your primary focus is maximizing value: Filter your wax thoroughly and craft it into high-demand products like pure beeswax candles, lip balms, or soaps for sale or personal use.

- If your primary focus is resourcefulness and bee health: Use the cold wash method and give the "wet" frames back to a strong hive so the bees can reclaim every last drop of honey.

By properly processing your wax cappings, you transform a sticky byproduct into one of the most versatile and valuable assets from your hive.

Summary Table:

| Processing Method | Best For | Key Consideration |

|---|---|---|

| Cold Water Wash | Quick separation, bee health | May not remove all honey; honey-water can be used as bee feed. |

| Melt & Separate | Pure wax for candles/cosmetics | Requires a double boiler; avoid overheating to prevent darkening. |

| Return 'Wet' Frames | Resourcefulness, bee health | Let bees clean frames to reclaim honey and prevent pests. |

Ready to maximize the value from every harvest?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, wholesale-focused supplies needed for efficient operations—from extraction to wax rendering. Let us help you equip your operation for maximum productivity and profitability.

Contact our expert team today to discuss your wholesale needs.

Visual Guide

Related Products

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction

- What is the importance of soaping the rollers during milling? Prevent Wax Adhesion & Equipment Downtime

- What is the primary function of a beeswax flatting and embossing machine? Optimize Your Foundation Production

- What are the sequential stages of operation for a beeswax flatting and embossing machine? Master High-Quality Wax Sheets

- What tools are used to add intricate details to beeswax sheets? Find the Right Embossing Method for Your Scale