Choosing the right electric honey extractor is a critical decision that directly impacts the efficiency and enjoyment of your harvest. The primary factors to weigh are the extractor's capacity (how many frames it holds), its material (typically stainless steel), the quality of the motor and its speed controls, and its overall design for stability and ease of cleaning.

An electric extractor is an investment in your most valuable resource: time. The decision hinges on accurately matching the machine's capacity and features to the current—and future—scale of your beekeeping operation.

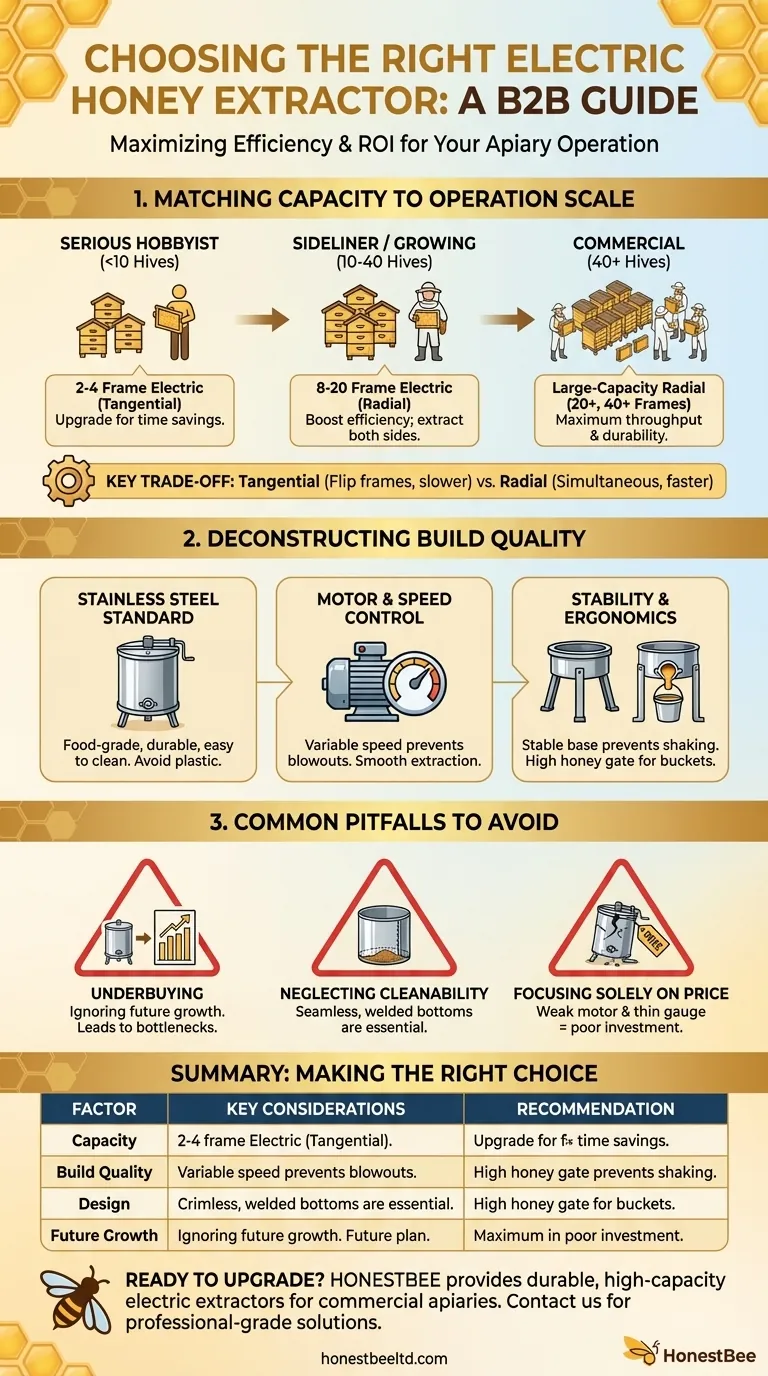

Matching Capacity to Your Operation

The number of hives you manage is the single most important factor. Buying an extractor that is too small creates a bottleneck, while overspending on a commercial-grade machine for a small apiary is an inefficient use of capital.

For the Serious Hobbyist (Up to 10 Hives)

For this scale, a 2- to 4-frame electric extractor is often sufficient. While a manual extractor is cheaper, the upgrade to electric saves significant physical effort and time, turning a laborious task into a manageable process.

These smaller models are typically tangential, meaning they require you to manually flip the frames to extract honey from the second side.

For the Sideliner or Growing Apiary (10-40 Hives)

Once you manage more than ten hives, efficiency becomes paramount. Look for an 8- to 20-frame electric extractor.

At this scale, you should strongly consider a radial design. Radial extractors position frames like spokes on a wheel, extracting honey from both sides simultaneously and eliminating the need to flip frames. This dramatically speeds up your workflow.

For the Commercial Beekeeper (40+ Hives)

Commercial operations require maximum throughput. The choice is a large-capacity radial extractor holding 20, 40, or even more frames.

Durability is key here. Focus on models with powerful motors, heavy-gauge stainless steel, and robust, professionally welded components that can withstand constant, heavy use.

Deconstructing the Extractor's Build Quality

Beyond simple capacity, the construction and features of the extractor determine its longevity and ease of use.

The Stainless Steel Standard

Food-grade stainless steel is the non-negotiable standard for any part of an extractor that touches honey. It is durable, will not rust, and is easy to clean and sanitize.

Avoid plastic extractors if possible. While cheaper, they can scratch, harbor bacteria, and may not withstand the stress of heavy use over time.

Motor and Speed Control

The primary advantage of an electric model is the motor. A quality extractor will offer variable speed control.

This is crucial for preventing "blowouts," where the force of extraction destroys new or delicate wax comb. Starting slowly and gradually increasing speed allows you to extract honey without damaging the frames.

Stability and Ergonomics

An extractor full of spinning honey frames generates immense force. The machine must have a stable base with well-designed legs to prevent violent shaking or "walking" across the floor during operation.

Consider the height of the honey gate (the drain). It must be high enough to allow you to easily fit a 5-gallon bucket with a strainer underneath, a small detail that makes a huge difference on extraction day.

Understanding the Key Trade-off: Tangential vs. Radial

Your choice between these two designs has the biggest impact on your time commitment.

Tangential Extractors

In a tangential extractor, the frame lies flat against the wall of the drum. Centrifugal force pulls honey from the outward-facing side only.

You must stop the machine, flip each frame by hand, and run the cycle again to extract from the other side. This is acceptable for a few hives but becomes a major time sink at a larger scale.

Radial Extractors

In a radial extractor, frames are loaded vertically like spokes in a wheel. The top bar faces the outer wall.

Centrifugal force pulls honey from both sides of the frame at once due to the slight upward angle of the cells. This design is vastly more efficient and is the standard for any serious or commercial beekeeper.

Common Pitfalls to Avoid

Making an informed choice means knowing what mistakes to sidestep.

Underbuying for Your Future Growth

A common error is buying an extractor that fits your needs today without considering your plans for next year. If you plan to expand your apiary, investing in a slightly larger or more efficient model now will save you from having to buy a second extractor later.

Neglecting Cleanability in the Design

Look closely at the interior. A tank with a seamless, welded bottom is far superior to one with a crimped or sealed seam. Those seams create a crevice where honey, wax, and propolis can accumulate, making cleaning difficult and posing a sanitation risk.

Focusing Solely on Price

A cheap extractor with a weak motor, thin-gauge steel, and a wobbly base is not a bargain. It will lead to frustration, potential equipment failure, and a lower-quality extraction process. View this purchase as a long-term investment in your operation's efficiency.

Making the Right Choice for Your Apiary

Your decision should be guided by a clear-eyed assessment of your goals.

- If your primary focus is time savings for a serious hobby: A 2- to 4-frame electric tangential extractor with variable speed is an excellent entry point.

- If your primary focus is scaling your operation efficiently: A mid-sized (8- to 20-frame) radial extractor is the best long-term investment for a growing apiary.

- If your primary focus is maximum throughput for a commercial business: A large-capacity (20+ frame) radial extractor with a heavy-duty build is the only professional choice.

By aligning your choice with your operational scale and future ambitions, you ensure your extractor becomes a powerful asset, not a limiting bottleneck.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Capacity | Match to hive count: 2-4 frames (hobbyist), 8-20 frames (sideliner), 20+ frames (commercial). |

| Build Quality | Food-grade stainless steel, powerful motor with variable speed control, stable base. |

| Design | Tangential (flip frames) vs. Radial (extract both sides simultaneously). |

| Future Growth | Consider expansion plans to avoid underbuying. |

Ready to upgrade your honey extraction process?

As a leading supplier to commercial apiaries and distributors, HONESTBEE provides durable, high-capacity electric honey extractors built for efficiency and long-term performance. Our wholesale-focused operations ensure you get professional-grade equipment that maximizes your harvest throughput.

Contact our team today to discuss the best extractor solution for your operation's scale and goals.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- Commercial Electric 12 Frame Honey Extractor Spinner Motorized Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 40 Frame Commercial Electric Honey Extractor for Beekeeping

People Also Ask

- What equipment is used for honey harvest? Essential Tools for Every Beekeeper

- How is honey extracted commercially? Maximize Your Apiary's Efficiency and Honey Yield

- What tool is used to extract honey? The Essential Guide to Honey Extractors & Harvesting

- What is the purpose of a honey extractor in beekeeping? Boost Hive Productivity & Honey Yields

- How do you extract honey from frames? Choose the Right Method for Your Apiary's Scale