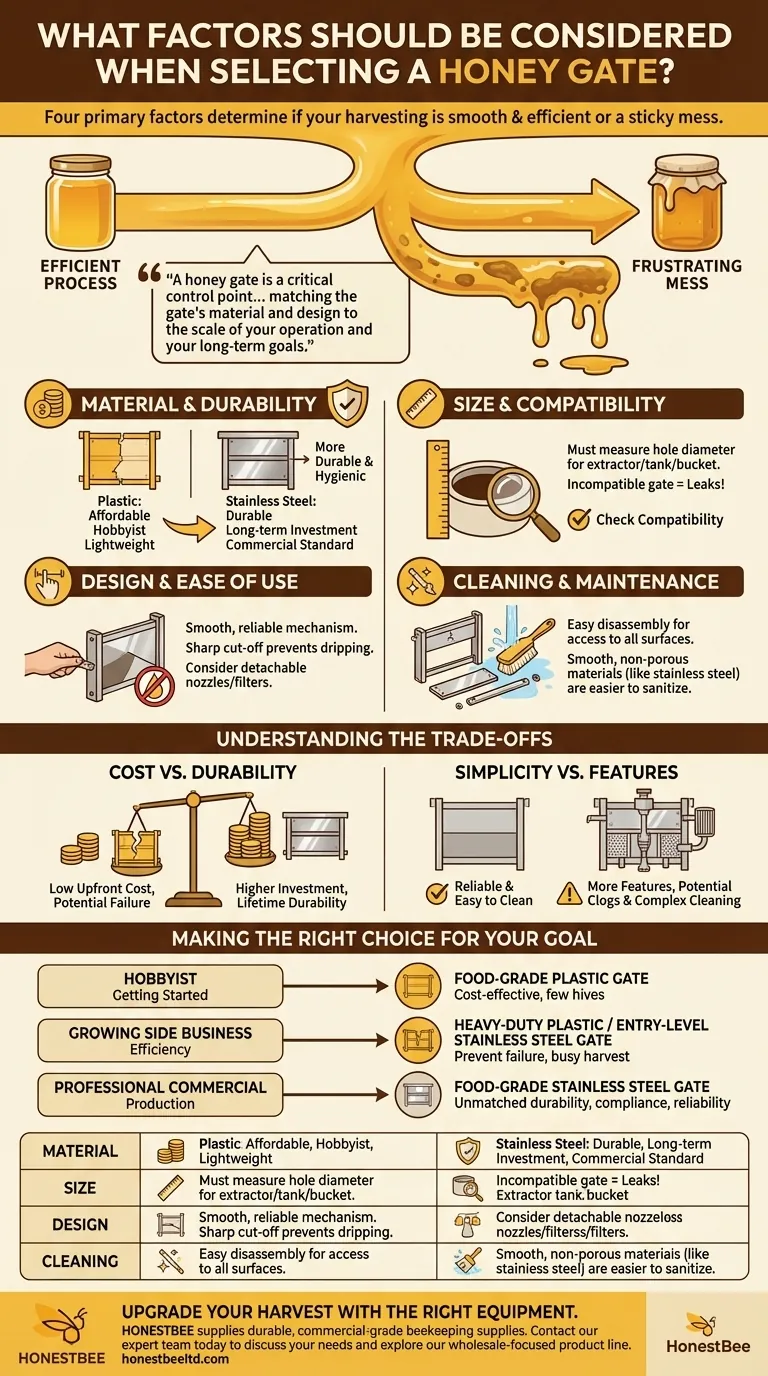

When selecting a honey gate, you must consider four primary factors: the material and its durability, the size and compatibility with your existing equipment, the gate's design for ease of use, and how simple it is to clean and maintain. These elements determine whether your honey harvesting is a smooth, efficient process or a sticky, frustrating mess.

A honey gate is more than just a tap; it's a critical control point in your extraction workflow. The central decision is not just about features, but about matching the gate's material and design to the scale of your operation and your long-term beekeeping goals.

The Core Factors in Honey Gate Selection

Choosing the right gate requires a clear understanding of how each component impacts your work. A poor choice can lead to leaks, clogs, and difficult cleanup, wasting both valuable honey and time.

Material: Plastic vs. Stainless Steel

The material is the most significant decision you will make. It dictates durability, longevity, and ease of sanitation.

Food-grade plastic is the most common and affordable option, making it an excellent starting point for new beekeepers. It is lightweight and functional for smaller-scale operations.

Stainless steel represents a long-term investment. It is exceptionally durable, will not warp or crack under pressure, and is far easier to clean and sanitize, making it the standard for serious hobbyists and commercial producers.

Size and Compatibility

A gate is useless if it doesn't fit your extractor, bottling tank, or bucket.

Before purchasing, you must measure the diameter of the hole in your container. While many gates are made for standard bucket sizes, variations are common, especially with older or custom equipment. An incompatible gate will result in frustrating leaks.

Design and Ease of Use

The mechanical design directly affects your control over the honey flow.

Look for a gate with a smooth, reliable opening and closing mechanism. A "guillotine" style gate should slide cleanly without sticking. Features like a sharp cut-off edge prevent dripping when you close the valve.

Some designs also include detachable nozzles or built-in filters, which can streamline the bottling process but may add complexity to cleaning.

Cleaning and Maintenance

Honey is sticky and can easily harbor bacteria if equipment is not properly cleaned.

A well-designed gate should be easy to disassemble. Gates with removable parts or a simple construction allow you to access all surfaces, ensuring no honey residue is left behind. Smooth, non-porous materials like stainless steel are inherently easier to sanitize.

Understanding the Trade-offs

The primary trade-off is between upfront cost and long-term value. It's crucial to be realistic about your needs to avoid overspending or buying a tool that quickly becomes a point of failure.

Cost vs. Durability

A plastic gate may only cost a few dollars, but its thumbscrews can strip and the body can crack over time. A stainless steel gate might cost significantly more, but it is a one-time purchase that can last a lifetime.

Simplicity vs. Features

Advanced features like integrated filters sound appealing but can become another component to clean or a potential point for clogs. For most applications, a simple, well-made gate is more reliable than a complex one.

Making the Right Choice for Your Goal

Your selection should be guided by the scale of your beekeeping and your commitment to the craft.

- If your primary focus is getting started as a hobbyist: A simple, food-grade plastic gate is the most cost-effective and practical choice for handling a few hives.

- If your primary focus is efficiency for a growing side business: Upgrading to a high-quality, heavy-duty plastic or an entry-level stainless steel gate will prevent equipment failure during a busy harvest.

- If your primary focus is professional, commercial-level production: Food-grade stainless steel is the only viable option for its unmatched durability, food-safety compliance, and operational reliability.

Choosing the right honey gate is a small decision that ensures a smooth and rewarding harvest.

Summary Table:

| Factor | Key Considerations |

|---|---|

| Material | Plastic (affordable, hobbyist) vs. Stainless Steel (durable, commercial) |

| Size & Compatibility | Must match the diameter of your extractor, tank, or bucket to prevent leaks. |

| Design & Ease of Use | Look for a smooth, non-stick mechanism and a sharp cut-off to prevent dripping. |

| Cleaning & Maintenance | Easy to disassemble and sanitize; stainless steel is easier to clean than plastic. |

Upgrade Your Harvest with the Right Equipment

A reliable honey gate is crucial for a smooth, efficient, and profitable harvest. At HONESTBEE, we supply durable, commercial-grade beekeeping supplies and equipment to serious hobbyists, commercial apiaries, and distributors.

We understand that the right tool makes all the difference. Let us help you select the perfect honey gate and other essential equipment to streamline your operation.

Contact our expert team today to discuss your needs and explore our wholesale-focused product line.

Visual Guide

Related Products

- Stainless Steel Honey Gate Valve Tap Tool for Honey Extractor

- Honey Gate Valve with Ergonomic Ball Handle Plastic Bee Honey Tap for Beekeeping Bottling and Honey Extractor Equipment

- Honeycomb Style Drip Free Honey Dispenser

- Premium Diamond-Faceted Glass Honey Dispenser

- Classic Honey Bear Jars with Flip Top Dispensing Cap for Liquid Sweeteners

People Also Ask

- What is a honey gate and how is it used in beekeeping equipment? Essential Tools for Precise Honey Bottling

- Can a honey gate be reused? Maximize the Lifespan of Your Beekeeping Extraction Equipment

- Under what conditions should the honey gate be closed? Prevent Messy Spills and Ensure Extraction Efficiency

- Can a honey gate be reused, and how should it be stored? Ensure Longevity for Your Honey Harvests

- What is the proper procedure for cleaning and maintaining a honey gate? Prolong Your Equipment's Life