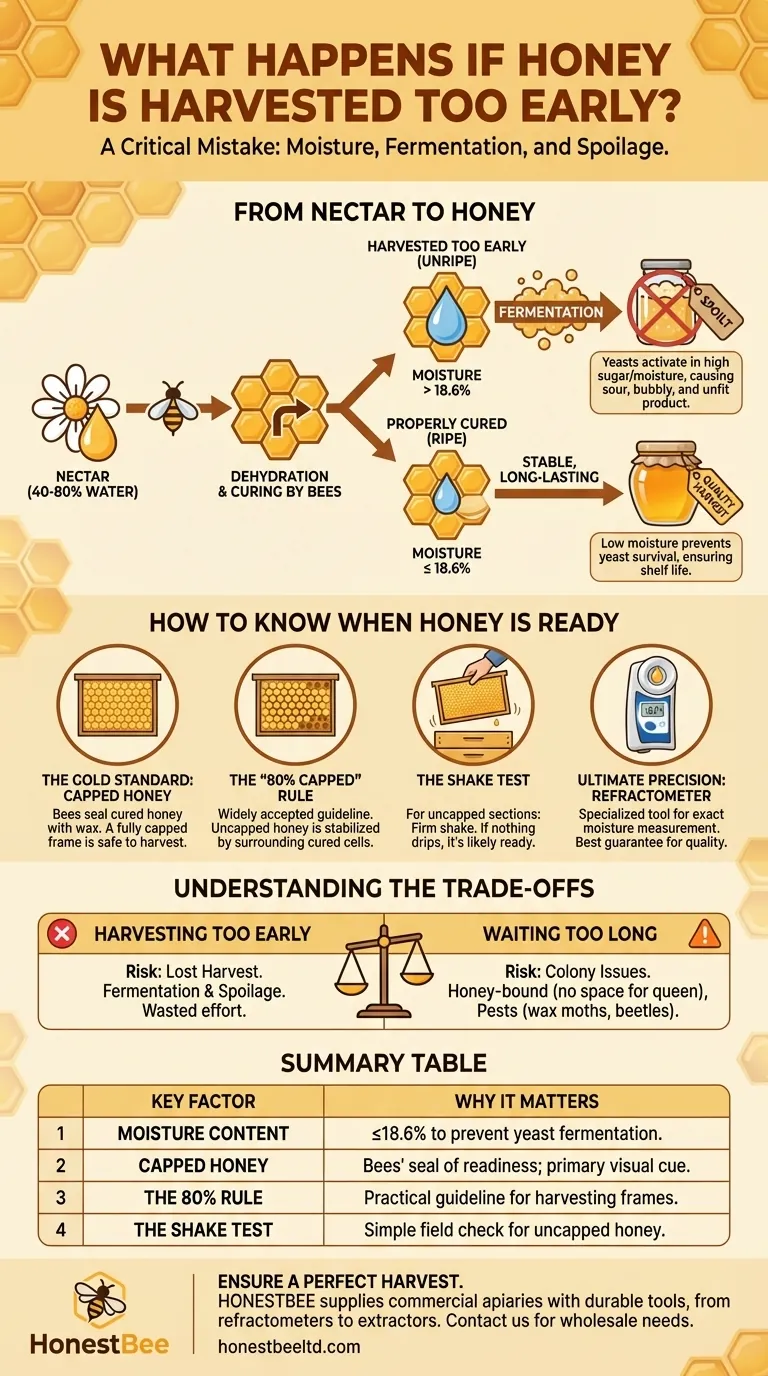

Harvesting honey too early is a critical mistake that compromises the entire harvest. If the honey's moisture content is too high, naturally occurring yeasts will activate and begin to ferment the sugars, resulting in a bubbly, sour, and spoiled product that is unfit for consumption.

The core issue is not time, but moisture. Honey isn't simply collected by bees; it's manufactured through a dehydration process. Harvesting before this process is complete means you are bottling unripe, unstable honey that will inevitably spoil.

Why Unripe Honey Fails

To avoid this outcome, you must understand the transformation from nectar to honey. This isn't an instantaneous process; it requires active work from the colony.

From Nectar to Honey: The Curing Process

Nectar collected from flowers has a very high water content, often between 40% and 80%. Bees begin the "curing" process by adding enzymes that break down complex sugars.

Back in the hive, they deposit the nectar into honeycomb cells and begin actively dehydrating it. They circulate air with their wings, fanning the nectar to evaporate excess water until the moisture content drops significantly.

The Critical Role of Moisture Content

The "magic number" for stable, long-lasting honey is a moisture content at or below 18.6%. Below this threshold, the high sugar concentration creates an environment where yeast and other microbes cannot survive or reproduce.

When honey is harvested above this level, especially above 20%, it becomes a perfect breeding ground for osmophilic yeasts that thrive in high-sugar environments.

The Consequence: Fermentation

Fermentation is the direct result of harvesting uncured honey. You may notice a sour or alcohol-like smell, a frothy or bubbly appearance, and an "off" taste.

Once honey begins to ferment, the process cannot be reversed. The entire batch is considered spoiled and must be discarded.

How to Know When Honey Is Ready

Your bees will give you clear signals that the honey is cured and ready for harvest. Learning to read these signs is the most important skill for a successful harvest.

The Gold Standard: Capped Honey

When the bees have reduced the moisture content to the correct level, they seal the honeycomb cell with a fresh wax cap. This capped honey is their finished, preserved food store.

A frame filled with capped honey is the clearest indicator that the contents are fully cured and safe to harvest.

The "80% Capped" Rule of Thumb

Beekeepers rarely wait for 100% of a frame to be capped. A widely accepted guideline is to harvest a frame when at least 80% of the cells are capped.

The small amount of uncapped honey on such a frame will typically have a low enough moisture content to be stabilized by the surrounding cured honey.

A Simple Field Method: The Shake Test

For uncapped sections, you can perform a shake test. Hold the frame horizontally over the open hive and give it a firm shake.

If nectar or thin honey drips out, its moisture content is too high, and it needs more time. If nothing drips, the honey is likely cured and ready.

For Ultimate Precision: The Refractometer

A honey refractometer is a specialized tool that provides a precise measurement of moisture content. By placing a single drop of honey on the lens, you can get an exact reading.

While not essential for hobbyists, it is the best way to guarantee your honey meets the standard for long-term storage or sale.

Understanding the Trade-offs

While harvesting too early is the primary risk, waiting too long can also present challenges. A successful beekeeper balances these factors.

The Risk of Harvesting Too Early

This is the most severe risk. It leads directly to a lost harvest due to fermentation and spoilage, wasting both the bees' efforts and your own.

The Risk of Waiting Too Long

If you leave fully capped honey in the hive for an extended period, the colony may become honey-bound. This means so much space is used for honey storage that the queen has no room to lay eggs, which can slow or stop the growth of the colony.

Furthermore, a large store of honey can attract pests like wax moths or small hive beetles if the colony isn't strong enough to defend it all.

Making the Right Choice for Your Harvest

Your decision should be based on a combination of visual cues and your specific goals as a beekeeper.

- If your primary focus is maximum quality and shelf life: Wait until frames are at least 80-90% capped, and verify the moisture content of any uncapped honey with a refractometer.

- If your primary focus is a small, personal-use harvest: The shake test combined with the "80% capped" rule is a reliable and sufficient method.

- If your primary focus is colony health and expansion: Harvest fully capped frames as they become ready to provide the queen with more space to lay, even if it means conducting multiple smaller harvests.

Patience and careful observation are your greatest assets. Trusting the bees' signal—the wax cap—is the foundation of every successful harvest.

Summary Table:

| Key Factor | Why It Matters |

|---|---|

| Moisture Content | Must be ≤18.6% to prevent yeast fermentation and spoilage. |

| Capped Honey | Bees seal cells with wax when honey is cured; the primary visual cue for readiness. |

| The 80% Rule | A frame is ready to harvest when at least 80% of the honeycomb cells are capped. |

| The Shake Test | If no liquid drips from an uncapped frame when shaken, the honey is likely ready. |

Ensure a perfect harvest every time with the right equipment.

HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, high-quality tools needed for success. From refractometers for precise moisture testing to robust honey extractors, our wholesale-focused operations provide the reliable gear that protects your harvest and supports your colony's health.

Contact us today to discuss your apiary's needs and discover how our equipment can contribute to your success.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

People Also Ask

- Why is a high-precision refractometer considered essential for honey quality? Master Moisture Control for Stability

- What should be considered regarding the measurement range of a honey refractometer? Ensure Peak Honey Quality

- What is the function of a honey refractometer in beekeeping? Ensure Harvest Quality and Prevent Fermentation

- What role does a high-precision refractometer play in honey moisture analysis? Ensure Honey Quality & Stability

- What is the primary function of a desktop refractometer? Ensure Honey Quality and Prevent Fermentation