At its core, a honey extractor is a mechanical device that uses centrifugal force to remove honey from honeycomb frames. Unlike destructive crush-and-strain methods, an extractor spins the frames at high speed, flinging the honey out against the drum walls without damaging the delicate wax comb. This allows beekeepers to return the empty combs to the hive, preserving a critical resource for the bees.

The true value of a honey extractor isn't just about harvesting honey efficiently. It's about respecting the immense energy bees expend to build their comb, allowing for a sustainable cycle that boosts both hive health and honey production.

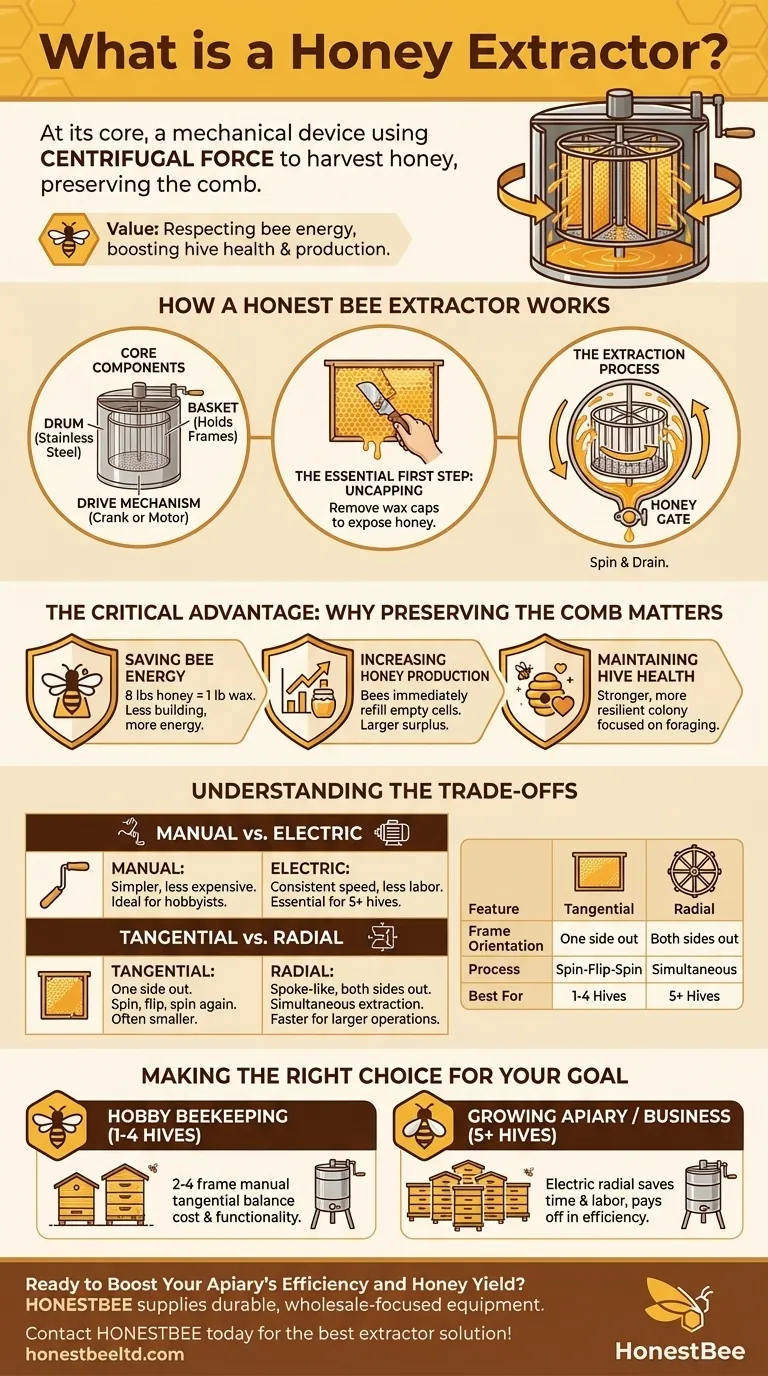

How a Honey Extractor Works

A honey extractor operates on a simple, powerful principle: centrifugal force. By spinning the honeycomb frames rapidly, it overcomes the honey's viscosity and pulls it from the individual wax cells.

The Core Components

An extractor consists of three main parts. The drum is a large, typically stainless steel cylinder that contains the operation. Inside, a basket or reel securely holds the honey frames. A drive mechanism, either a manual hand-crank or an electric motor, spins this central basket.

The Essential First Step: Uncapping

Before extraction, the beekeeper must "uncap" the honey. Bees seal each cell of cured honey with a fresh layer of beeswax. This cap must be carefully sliced off with a special knife or tool to expose the honey within the cells.

The Extraction Process

Once uncapped frames are placed in the basket, the crank or motor is engaged. As the basket spins, honey is flung outward from the cells and splatters against the inner wall of the drum. Gravity then pulls the liquid honey down to the sloped floor of the extractor, where it pools and can be drained through a tap, often called a honey gate.

The Critical Advantage: Why Preserving the Comb Matters

The single most important benefit of using an extractor is the preservation of the wax comb. This is not a minor convenience; it is fundamental to productive and sustainable beekeeping.

Saving Bee Energy

Bees must consume approximately eight pounds of honey to produce a single pound of beeswax. Building comb is one of the most energy-intensive tasks a colony undertakes. By returning empty combs, you save the bees a monumental amount of work.

Increasing Honey Production

Because the bees don't have to rebuild their entire pantry from scratch, they can immediately begin refilling the empty cells with new nectar. This redirected energy directly translates into a larger honey surplus for both the colony and the beekeeper.

Maintaining Hive Health

A colony that can focus on foraging and raising brood instead of constantly rebuilding wax is a stronger, more resilient colony. Preserving drawn comb reduces stress on the bees and contributes to the overall health of the hive.

Understanding the Trade-offs

While the principle is the same, extractors come in different designs and sizes, each with specific trade-offs.

Manual vs. Electric

Manual extractors are powered by a hand crank. They are simpler, less expensive, and ideal for hobbyists with only a few hives. Electric extractors use a motor, offering consistent speed and significantly reducing physical labor, making them a necessity for anyone with more than five or six hives.

Tangential vs. Radial

In a tangential extractor, the frames are placed with one side of the comb facing outward. You must spin, flip the frames, and spin again to extract honey from both sides. They are often smaller and more affordable.

In a radial extractor, frames are positioned like spokes on a wheel. Centrifugal force extracts honey from both sides of the comb simultaneously, making the process much faster and more efficient for larger operations.

Making the Right Choice for Your Goal

Selecting an extractor depends entirely on the scale of your beekeeping and your long-term goals.

- If your primary focus is hobby beekeeping (1-4 hives): A small, 2- or 4-frame manual tangential extractor offers the best balance of cost and functionality.

- If your primary focus is a growing apiary or sideline business (5+ hives): Investing in an electric radial extractor will save you immense time and labor, quickly paying for itself in efficiency.

Using a honey extractor elevates beekeeping from simple harvesting to a partnership that respects the tireless work of your bees.

Summary Table:

| Feature | Tangential Extractor | Radial Extractor |

|---|---|---|

| Frame Orientation | One side faces out | Both sides face out (spoke-like) |

| Process | Spin, flip frames, spin again | Extract both sides simultaneously |

| Best For | Hobbyists, smaller operations (1-4 hives) | Larger apiaries, sideline businesses (5+ hives) |

Ready to Boost Your Apiary's Efficiency and Honey Yield?

A high-quality honey extractor is an investment that pays for itself by saving your bees energy and maximizing your harvest. Whether you're a commercial apiary or a beekeeping equipment distributor, HONESTBEE supplies the durable, wholesale-focused equipment you need to succeed.

Contact HONESTBEE today to discuss the best extractor solution for your operation!

Visual Guide

Related Products

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- How long does it take to extract honey with an electric extractor? Cut extraction time to minutes.

- What is the energy consumption like for automatic honey extractors? Maximize Your Harvest Efficiency

- What are the advantages of automated honey extractors in terms of time efficiency? Boost Your Harvest Speed

- Why is preserving honeycomb integrity important, and how do automated extractors help? Boost Hive Health & Honey Yields

- What are the advantages of electric honey extractors? Boost Efficiency for Your Commercial Apiary