At its core, a honey filling machine is specialized equipment designed to accurately and efficiently package honey into various containers. It automates the filling process, providing a consistent volume in every jar while overcoming the natural challenges of working with a highly viscous product like honey.

The true value of a honey filling machine isn't just packaging; it's about transforming a slow, inconsistent manual task into a professional, efficient, and cost-effective operation that enhances product quality and brand reputation.

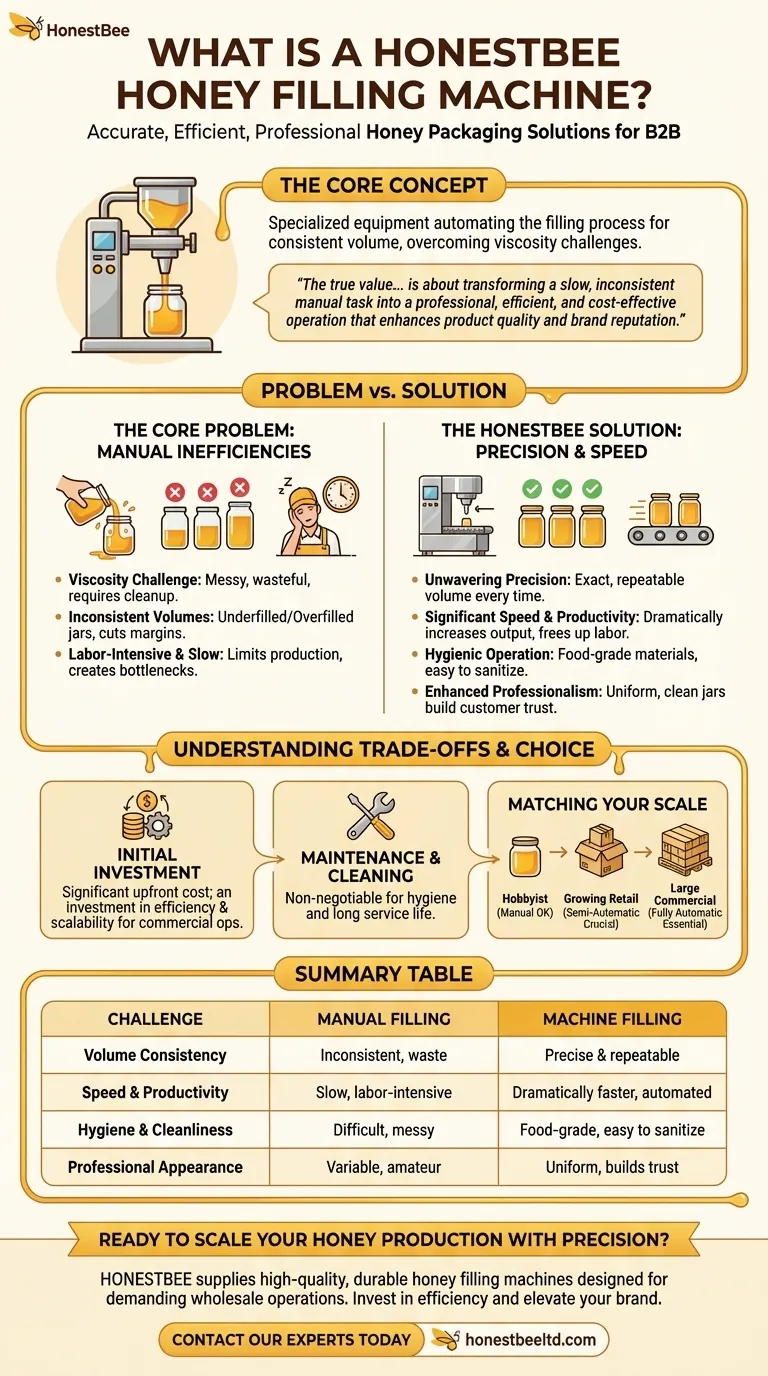

The Core Problem: Why Manual Honey Filling is Inefficient

Before understanding the solution, it's crucial to recognize the inherent challenges of packaging honey by hand. These issues are what drive the need for specialized equipment.

The Viscosity Challenge

Honey's thick, sticky nature makes manual pouring difficult. It leads to drips, messes, and significant product waste, requiring extensive cleanup and reducing overall profitability.

Inconsistent Volumes

Manually filling jars almost guarantees variation. This results in underfilled jars that disappoint customers and overfilled jars that cut directly into your margins.

Labor-Intensive and Slow

The manual process is inherently slow and requires significant hands-on time. This limits production capacity and increases labor costs, creating a bottleneck for any growing business.

How a Honey Filling Machine Solves These Problems

A dedicated filling machine directly addresses the inefficiencies of manual work by introducing precision, speed, and hygiene into the packaging workflow.

Unwavering Precision and Consistency

The primary function of a honey filler is to deliver an exact, repeatable volume of product every single time. This eliminates costly overfilling and ensures a consistent, professional presentation that builds customer trust.

Significant Speed and Productivity

By automating the most time-consuming part of packaging, these machines dramatically increase output. What might take hours to do by hand can often be accomplished in minutes, freeing up valuable time and labor.

Hygienic, Food-Grade Operation

Professional machines are built with food-grade materials, such as stainless steel, that are easy to clean and sanitize. This is critical for maintaining product purity and adhering to food safety standards.

Enhanced Professionalism

A line of perfectly and cleanly filled jars on a shelf communicates quality and reliability. The machine gives your product a professional touch that is essential for competing in a retail environment.

Understanding the Trade-offs

While the benefits are clear, adopting this technology requires a practical assessment of its implications for your specific operation.

Initial Capital Investment

A honey filling machine is a significant upfront expense. For small-scale hobbyists, the cost may be prohibitive, but for a commercial operation, it's an investment in efficiency and scalability.

Maintenance and Cleaning

Like any piece of food processing equipment, these machines require diligent cleaning and regular maintenance. This is a non-negotiable step to ensure hygienic operation and a long service life.

Matching the Machine to Your Scale

Machines range from small, semi-automatic tabletop models to large, fully automated industrial lines. Choosing the wrong size can lead to a new bottleneck or an inefficient use of capital.

Making the Right Choice for Your Operation

Selecting the right equipment depends entirely on your production goals and business scale.

- If your primary focus is small-batch or hobbyist sales: The precision of a machine may not be necessary, and careful manual methods can suffice without the capital investment.

- If your primary focus is growing and entering retail markets: A semi-automatic filling machine is crucial for achieving the product consistency and professional appearance that retailers and customers expect.

- If your primary focus is large-scale commercial production: A fully automatic filling line is essential for maximizing productivity, minimizing labor costs, and ensuring high-volume consistency.

Ultimately, investing in the right filling technology is about gaining control over your product's quality, consistency, and profitability.

Summary Table:

| Challenge | Manual Filling | Machine Filling |

|---|---|---|

| Volume Consistency | Inconsistent, leads to waste | Precise and repeatable every time |

| Speed & Productivity | Slow, labor-intensive | Dramatically faster, automates the process |

| Hygiene & Cleanliness | Difficult to control, messy | Food-grade materials, easy to sanitize |

| Professional Appearance | Variable, can look amateur | Uniform, builds customer trust |

Ready to Scale Your Honey Production with Precision?

As your business grows, consistent, professional packaging becomes essential. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with high-quality, durable honey filling machines designed for demanding wholesale operations.

Invest in equipment that maximizes your efficiency, protects your margins, and elevates your brand. Contact our experts today to find the perfect filling solution for your scale and budget.

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Commercial Rotary Honey Filling Machine for Production

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- What are the benefits of high-precision automatic filling machinery? Scale Your Honey Business Profitably

- What are the core benefits of using industrial-grade honey-filling equipment? Scale Your Apiary to Global Success

- What role does automated honey-filling machinery play? Scale Production and Precision for Commercial Apiaries

- How does high-precision filling equipment ensure quality and efficiency? Optimize Your Honey Packaging Performance

- What role does an industrial honey filling machine play in scaling commercial beekeeping? Boost Speed and Precision

- What are the technical advantages of using automatic honey-filling machines? Boost Efficiency and Product Purity

- What is the importance of professional honey processing and filling equipment? Scale Your Brand and Quality

- What additional support is available for selecting a honey packaging machine? Get Expert Guidance for Your Apiary