In simple terms, honey filtration is an industrial process that removes fine particles, including larger pollen grains, air bubbles, and other microscopic impurities from raw honey. This process is primarily used in large-scale commercial production to create a visually clear product and to significantly delay the natural process of crystallization.

The core purpose of filtration is to improve the honey's aesthetic appeal and shelf stability. It does not remove the honey's natural sugars or nectar, nor does it diminish its fundamental nutritional properties.

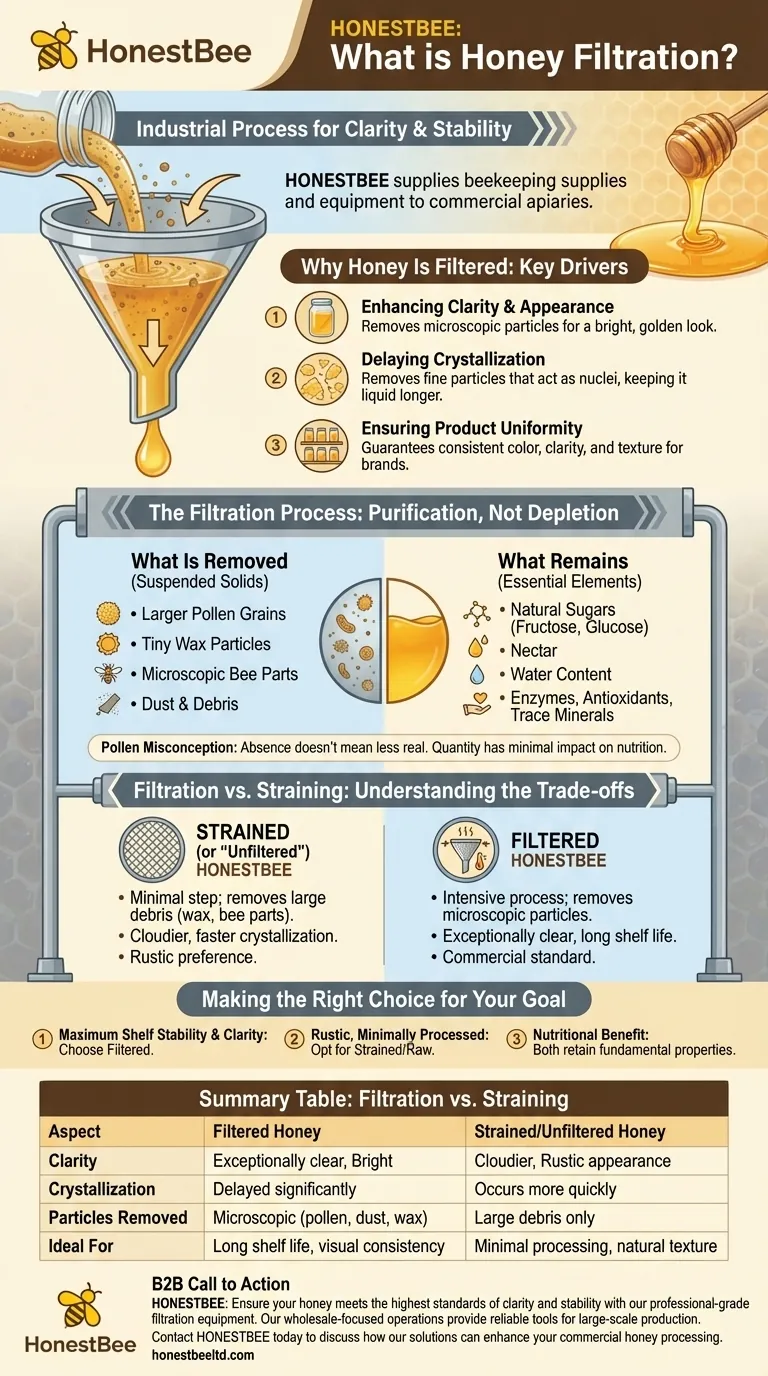

Why is Honey Filtered? The Drivers Behind the Process

While raw honey is perfectly edible after basic straining, commercial filtration is performed for specific market-driven reasons. It addresses consumer expectations and the logistical demands of a long supply chain.

Enhancing Clarity and Appearance

Consumers often associate high-quality honey with a bright, clear, golden liquid. Filtration removes the microscopic particles, like pollen and dust, that can make honey appear cloudy or hazy, resulting in the pristine clarity seen on most supermarket shelves.

Delaying Crystallization

Crystallization is a natural process where the glucose in honey separates from water and forms sugar crystals. Fine, suspended particles act as nuclei, or starting points, for these crystals to grow. By filtering out these particles, producers can keep the honey in a liquid state for much longer.

Ensuring Product Uniformity

For national and international brands, consistency is critical. Filtration helps ensure that every jar of honey has the same color, clarity, and texture, regardless of its specific floral origin or the season it was harvested.

What Filtration Removes (and What It Doesn't)

Understanding the distinction between what is taken out and what remains is key to demystifying the filtration process. The goal is purification, not depletion.

What Is Removed

The process is designed to remove suspended solids that are not part of the liquid honey itself. This includes:

- Larger pollen grains

- Tiny wax particles

- Microscopic bee parts

- Dust and other airborne debris

What Remains

Filtration does not alter the fundamental composition of the honey. The essential elements that make honey what it is are left fully intact, including:

- Natural sugars (fructose and glucose)

- Nectar

- Water content

- Enzymes, antioxidants, and trace minerals

The Misconception About Pollen

The removal of pollen is often a point of confusion. While pollen is useful for identifying the honey's floral source in a lab, its absence does not make the honey less "real" or "natural." The quantity of pollen present is not significant enough to impact the proven nutritional benefits of consuming honey.

Understanding the Trade-offs: Filtration vs. Straining

The terms "filtered" and "strained" are often used interchangeably, but they describe very different levels of processing.

The Purpose of Straining

Straining is a minimal, necessary step for virtually all honey. It involves passing the honey through a basic mesh or screen to remove large, visible debris like wax chunks, bee wings, and wood splinters from the hive. Honey labeled "raw" or "unfiltered" has almost always been strained.

The Purpose of Filtration

Filtration is a more intensive, secondary process. It often involves applying pressure to force the honey through a very fine filter, sometimes with the gentle application of heat to reduce its viscosity. This is what removes the microscopic particles that straining leaves behind.

The Impact on the Final Product

Strained (or "unfiltered") honey is often cloudier and will crystallize much more quickly due to the remaining particles. Many consumers prefer its rustic texture and minimally processed nature.

Filtered honey is exceptionally clear and remains liquid on the shelf for an extended period. This is the standard for most commercial honey brands seeking a stable and visually consistent product.

Making the Right Choice for Your Goal

Your choice between filtered and unfiltered honey should be based on your personal preference for texture and appearance, not on a perceived difference in quality or health benefits.

- If your primary focus is maximum shelf stability and a clear, liquid honey: Choose filtered honey, as it is specifically processed to delay crystallization and maintain a uniform appearance.

- If your primary focus is a more rustic, minimally-processed product: Opt for "strained" or "raw" honey, accepting that it may be cloudier and will crystallize more quickly.

- If your primary focus is nutritional benefit: Recognize that both filtered and strained honey retain their fundamental sugars, enzymes, and antioxidant properties.

Ultimately, understanding the purpose of filtration allows you to choose honey based on your preference for texture and appearance, not on a misconception of purity.

Summary Table:

| Aspect | Filtered Honey | Strained/Unfiltered Honey |

|---|---|---|

| Clarity | Exceptionally clear, bright | Cloudier, more rustic appearance |

| Crystallization | Delayed significantly | Occurs more quickly |

| Particles Removed | Microscopic (pollen, dust, wax) | Large debris only (wax chunks, bee parts) |

| Ideal For | Long shelf life, visual consistency | Minimal processing, natural texture |

HONESTBEE supplies beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors. Ensure your honey meets the highest standards of clarity and stability with our professional-grade filtration equipment. Our wholesale-focused operations provide the reliable tools you need for large-scale production. Contact HONESTBEE today to discuss how our solutions can enhance your commercial honey processing.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Thermostatic Conical Honey Melter

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- 10L Stainless Steel Electric Honey Press Machine

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- What are the benefits of a honey concentrator? Elevate Your Honey Quality and Market Value

- What is required for the cooling system when using circulating water in the honey vacuum thickener? Essential Components for Efficient Processing

- How is the cooling system configured when using tap water in the honey vacuum thickener? A Simple Guide for Beekeepers

- What are the benefits of motorized honey extractors? Save Time & Labor in Your Apiary

- What are the main components of the honey vacuum thickener equipment? A Guide to Preserving Honey Quality