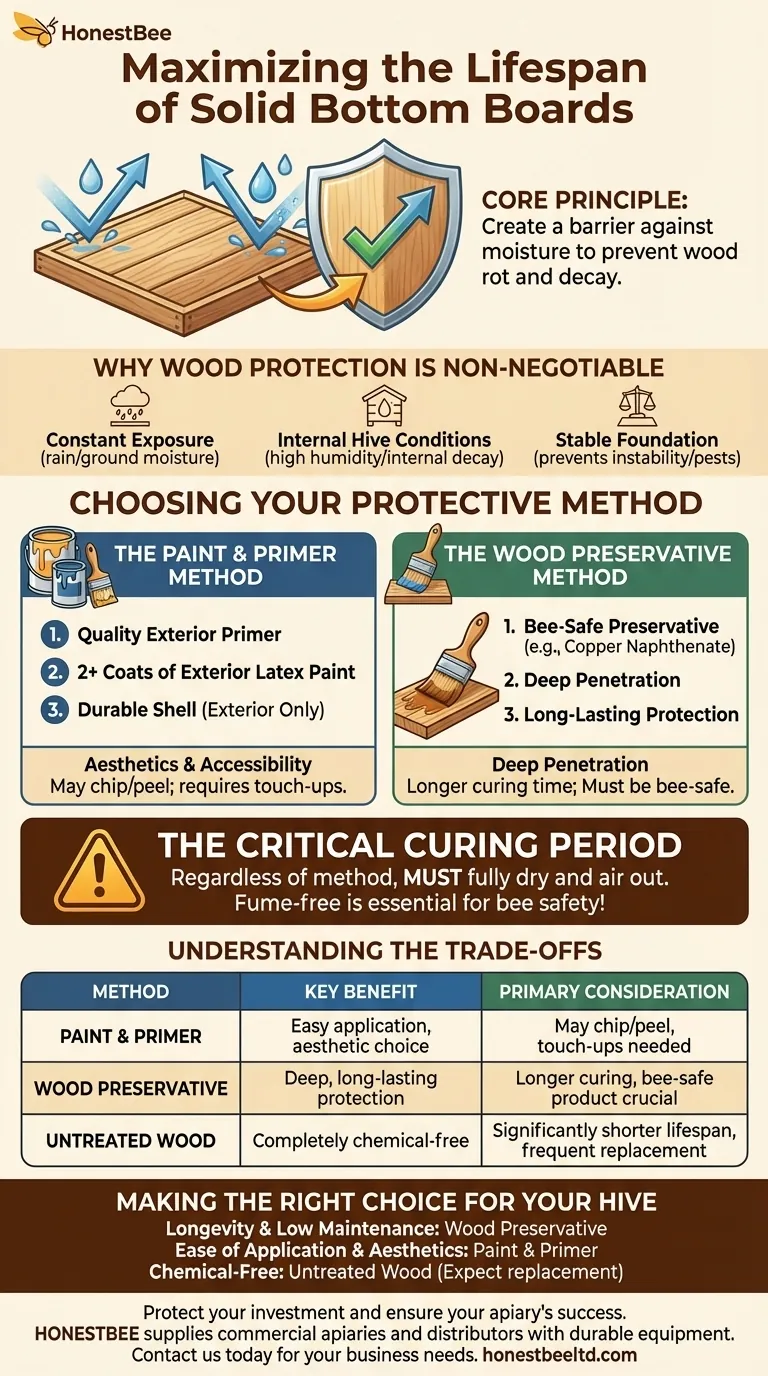

To maximize the lifespan of your solid bottom boards, you must protect the wood from the elements. The most effective methods are to either coat the exterior with a high-quality primer and paint or to treat the raw wood with a bee-safe wood preservative. Crucially, the board must be allowed to fully dry and air out until it is completely fume-free before being introduced to a colony.

The core principle is creating a barrier against moisture, which is the primary cause of wood rot and decay. While both painting and using preservatives are effective, your choice depends on a balance between ease of application, long-term durability, and your personal beekeeping philosophy.

Why Wood Protection is Non-Negotiable

A solid bottom board serves as the foundation of your hive, and its integrity is paramount. Leaving it untreated exposes it to forces that will drastically shorten its service life.

Constant Exposure to the Elements

The bottom board is in closest proximity to the ground, making it highly susceptible to moisture from rain, snowmelt, and damp air. This constant exposure is the leading cause of rot.

Internal Hive Conditions

Bees maintain a high-humidity environment inside the hive. This internal moisture can also contribute to wood decay from the inside out if the wood is not properly sealed.

A Stable Foundation for Your Colony

A rotting or compromised bottom board can create instability, unwanted entrances for pests, and poor insulation. Protecting the wood ensures a secure and stable home for your bees.

Choosing Your Protective Method

Both painting and using preservatives are excellent options, but they have different application processes and considerations.

The Paint & Primer Method

This is the most common approach for beekeepers. Using a quality exterior-grade latex primer and at least two top coats of exterior latex paint creates a durable, protective shell.

Many beekeepers choose to paint only the exterior surfaces of the bottom board, leaving the interior wood raw for the bees.

The Wood Preservative Method

Treating the wood with a preservative allows the protective compounds to soak into the wood fibers, offering deep protection rather than just a surface coating.

It is absolutely critical to select a preservative that is rated as safe for bees once fully cured, such as a copper naphthenate solution.

The Critical Curing Period

Regardless of the method you choose, this step cannot be skipped. Fresh paint or preservatives release volatile organic compounds (VOCs) that are harmful to bees.

Allow the bottom board to air out in a well-ventilated area for several days, or even weeks, until you can no longer detect any chemical odor.

Understanding the Trade-offs

Each method of wood protection comes with its own set of considerations. There is no single "best" answer, only what is best for your specific situation.

Paint: Aesthetics and Accessibility

Paint is widely available and allows you to customize the color of your hive equipment. However, it can chip or peel over time, especially around the high-traffic entrance, and may require periodic touch-ups.

Preservatives: Deep Penetration

Preservatives offer excellent, long-lasting protection that won't chip or peel. The primary drawbacks are the need for a longer curing time to dissipate strong odors and the importance of carefully selecting a bee-safe product.

Untreated Wood: The Natural Approach

Some beekeepers prefer to use no treatments at all. While this avoids all chemicals, it means you must accept a significantly shorter lifespan and plan to replace the bottom boards every few years.

Making the Right Choice for Your Hive

Select your method based on your goals for maintenance, longevity, and beekeeping philosophy.

- If your primary focus is longevity and low maintenance: Treating the wood with a properly cured, bee-safe preservative offers deep, lasting protection.

- If your primary focus is ease of application and aesthetics: A quality exterior primer followed by several coats of latex paint is a reliable and popular choice.

- If your primary focus is a completely chemical-free hive: Use untreated wood, but be prepared to monitor it for decay and replace it more frequently.

Protecting your woodenware is a foundational investment in the health of your colony and the sustainability of your beekeeping practice.

Summary Table:

| Method | Key Benefit | Primary Consideration |

|---|---|---|

| Paint & Primer | Easy application, aesthetic choice | May chip/peel over time, requires touch-ups |

| Wood Preservative | Deep, long-lasting protection | Requires longer curing time, must be bee-safe |

| Untreated Wood | Completely chemical-free | Significantly shorter lifespan, frequent replacement |

Protect your investment and ensure your apiary's success. At HONESTBEE, we supply commercial apiaries and distributors with the durable beekeeping equipment needed for long-term hive health. Our wholesale-focused operations provide the reliable supplies your business depends on. Contact us today to discuss your equipment needs and build a stronger foundation for your colonies.

Visual Guide

Related Products

- Metal Bee Hive Stand Bee Box Stand for Beekeeping

- Metal Hive Feet Bee Hive Stand for Ant Protection

- Professional Ant-Proof Beehive Stand with Integrated Moat for Beekeeping

- Plastic Bee Hive Stand for Beekeeping

- Langstroth Screen Bottom Board for Beekeeping Wholesale

People Also Ask

- Why is 8-frame vs 10-frame beekeeping equipment a critical decision? Optimize Your Apiary Infrastructure Today

- What are the advantages of using movable-frame hives? Maximize Yield with Langstroth Design

- What is the hive box or brood chamber in a beehive? Essential Guide to the Colony's Biological Engine

- How does a double-layer hive structure facilitate honeybee colony propagation? Grow Your Apiary with Strategic Splitting

- What is the significance of using standardized Dadant hives in honey bee health research? Drive Scientific Precision

- Why are standard Langstroth hives considered an ideal platform for beekeeping research? Ensure Precise Scientific Data

- What is the purpose of a garden hive lid in beekeeping? Essential Protection for Your Colony's Health

- What are the advantages of the Langstroth hive system? Boost Honey Yields with Modern Commercial Beekeeping