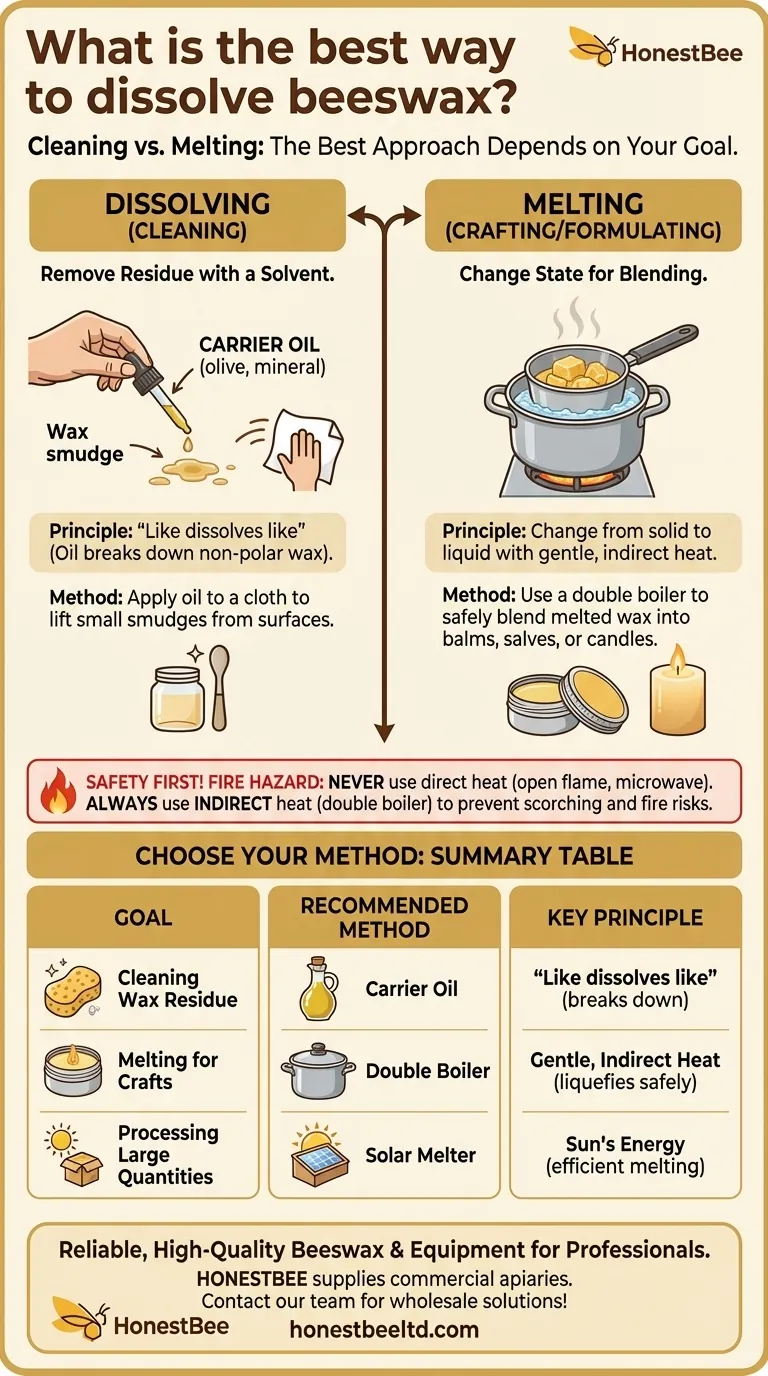

The best way to dissolve beeswax depends entirely on your goal. For cleaning small amounts of wax residue from a surface, a carrier oil like olive or mineral oil is the most effective solvent. For incorporating beeswax into products like balms or candles, you don't dissolve it but rather melt it gently into other oils using indirect heat.

The core principle to remember is this: Use an oil as a solvent for cleaning, but use gentle, indirect heat (like a double boiler) to melt beeswax for crafting and formulations. Direct heat is a significant fire hazard.

Dissolving vs. Melting: Choosing the Right Technique

The term "dissolve" can be misleading when it comes to beeswax. Understanding the difference between dissolving wax for cleanup and melting it for production is the key to getting the result you want safely and effectively.

The "Dissolving" Method for Cleaning

This technique uses a solvent to break down and remove unwanted beeswax from surfaces.

The principle at work is "like dissolves like." Beeswax is a non-polar substance made of fats and esters, so it dissolves in other non-polar substances, like oil.

To clean wax residue, simply apply a small amount of any common oil (olive, mineral, or coconut oil all work well) to a paper towel or cloth and rub the wax spot. The oil will act as a solvent, lifting the wax from the surface.

This method is ideal for removing small smudges from jars, countertops, or tools.

The "Melting" Method for Formulations

This technique uses heat to liquefy solid beeswax so it can be blended with other ingredients to create a new product.

The goal here is not to break the wax down but to change its physical state from solid to liquid. Once melted, it can be combined uniformly with oils to make salves, balms, furniture polishes, or candles.

This is the correct approach when beeswax is a primary ingredient in your project.

How to Safely Melt Beeswax

Because beeswax is flammable, applying heat correctly is a critical safety measure. Never heat beeswax over an open flame or in a microwave.

The Importance of Indirect Heat

Direct heat can easily scorch the wax, ruining its properties and color. More importantly, it can raise the temperature past its flash point (around 400°F or 204°C), creating a serious fire risk.

Indirect heat provides a gentle, controlled, and even temperature that safely melts the wax without danger.

The Double Boiler Method

This is the most accessible and reliable method for most projects. If you don't own a double boiler, you can easily create one.

Place a small pot inside a larger pot that contains a few inches of simmering water. The beeswax and any oils you are combining go into the smaller, inner pot. The steam from the water provides gentle heat to melt the contents safely.

The Solar Melter Method

For beekeepers or those processing large quantities of raw comb, a solar melter is a highly efficient option.

This device is essentially a glass-topped insulated box that uses the sun's natural energy to melt the wax. The melted wax drips through a filter and is collected in a tray, separating it from impurities.

Understanding the Trade-offs and Risks

Choosing the right method requires understanding the limitations and potential dangers of working with beeswax.

The Limits of Oil for Cleaning

While oil is an excellent solvent for beeswax, it is best suited for small-scale cleanup. Using it on a large area can become messy, and the oily residue left behind will likely need to be cleaned with soap and water.

The Flammability Risk of Melting

This cannot be overstated. A pot of wax left unattended on a direct heat source is a significant fire hazard. Always use a double boiler and never walk away from melting wax.

Making the Right Choice for Your Goal

Your specific task determines the correct approach.

- If your primary focus is cleaning beeswax residue: Use a small amount of any carrier oil on a cloth to dissolve and wipe away the wax from the surface.

- If your primary focus is making a balm, salve, or polish: Gently melt the beeswax with your chosen oils using a double boiler for maximum safety and control.

- If your primary focus is processing large amounts of raw wax: Consider a purpose-built solar melter for an efficient and energy-free method.

Ultimately, working with beeswax is simple and safe when you match your technique to your goal.

Summary Table:

| Goal | Recommended Method | Key Principle |

|---|---|---|

| Cleaning Wax Residue | Use a carrier oil (e.g., olive, mineral oil) | 'Like dissolves like' – oil breaks down wax |

| Melting for Crafts (Balms, Candles) | Use a double boiler for indirect heat | Gentle heat safely changes wax from solid to liquid |

| Processing Large Quantities | Use a solar melter | Sun's energy melts wax efficiently and safely |

Need reliable, high-quality beeswax or professional beekeeping equipment? HONESTBEE supplies commercial apiaries and distributors with the durable supplies they need to operate safely and efficiently. Whether you're processing wax or scaling your operation, our wholesale-focused solutions are designed for professionals. Contact our team today to discuss your needs and get a quote!

Visual Guide

Related Products

- Fully Automatic Beeswax Embossing Machine Foundation Mill

- Beeswax Machine Press Embosser Wax Foundation Mold Printer Bee Hive Equipment Making Sheet

- Silicone Rubber Honey Drum Heating Belt

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- HONESTBEE Classic Twist Up Lip Balm Tubes

People Also Ask

- Why is the precise hexagonal geometry of the rollers critical? Master Beeswax Foundation Quality for Higher Yields

- What are the primary applications of fully automatic wax foundation machines? Maximize Your Apiary Production Efficiency

- What is the primary function of a manual honeycomb embossing machine? Create Custom Beeswax Foundations with Ease

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction

- What role do embossed beeswax foundation sheets play in experiments? Essential Oil Stimulation & Wax Production Analysis