For processing impure beeswax from old honeycomb or cappings, the most effective method is a solar wax melter. This approach is superior because it simultaneously melts and purifies the wax in a single, passive step, using the sun's free energy to separate clean wax from honey and solid debris.

The core challenge of processing raw beeswax isn't just melting it, but separating it from impurities like honey, propolis, and debris. While direct heating offers speed, a solar melter provides simplicity and superior purification, making it the ideal choice for producing high-quality, clean wax with minimal effort.

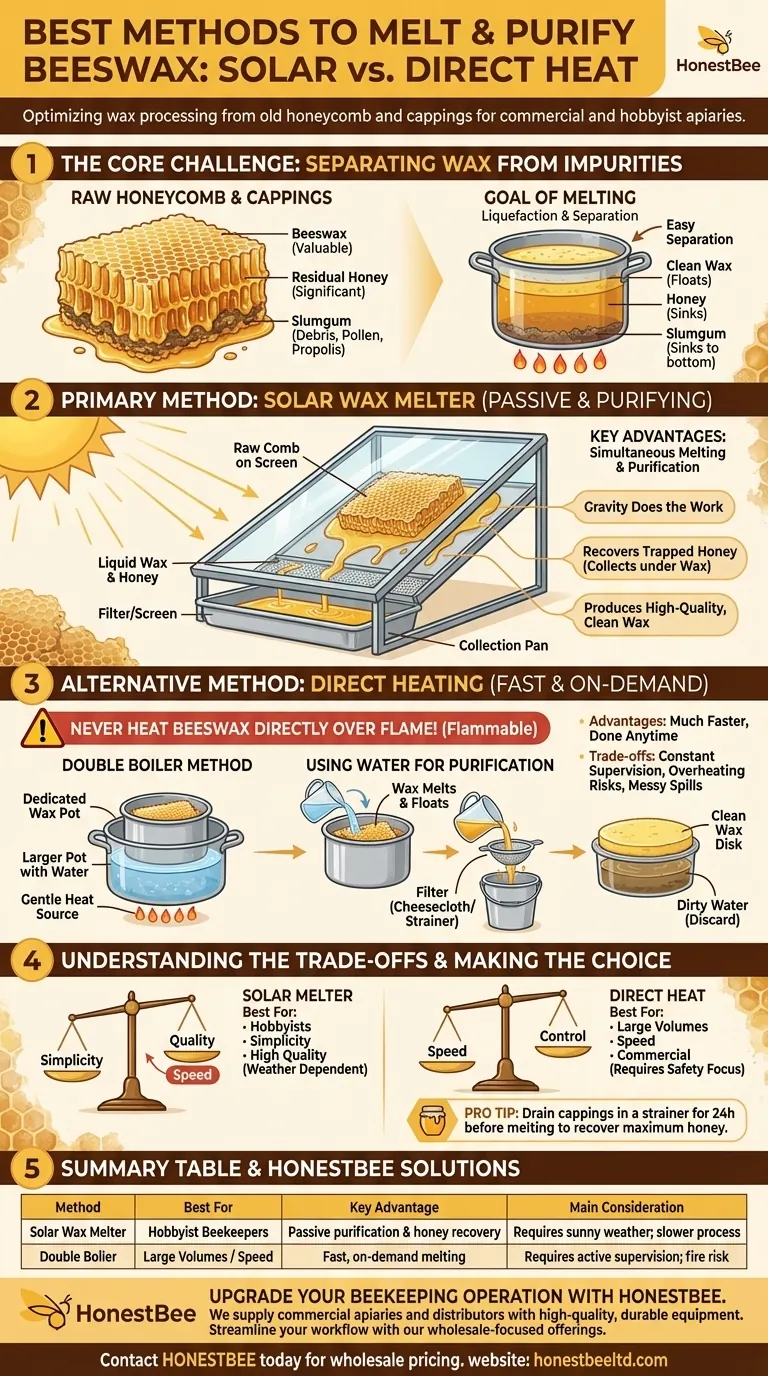

The Core Challenge: Separating Wax from Impurities

What's In Raw Honeycomb?

Raw honeycomb and cappings are not pure wax. They are a mixture of materials that must be separated.

This mixture typically includes:

- Beeswax: The valuable product you want to harvest.

- Residual Honey: A significant amount of honey often remains trapped in the cells and cappings.

- "Slumgum": This term refers to the collection of non-wax debris, including old brood cocoons, pollen, propolis, and dirt.

The Goal of Melting

The primary goal of melting is to liquefy the beeswax so it can separate from these other components. Clean wax floats, while honey and heavier slumgum sink, allowing for easy separation.

Primary Method: The Solar Wax Melter

A solar wax melter is widely considered the best tool for rendering wax from old comb due to its efficiency and simplicity.

How It Works

A solar melter is essentially a dark, insulated box with a tilted glass or plexiglass lid. Inside, raw comb is placed on a screen or pan.

The sun's heat builds up inside the box, melting the wax. The liquid wax runs down a sloped surface and through a filter or screen, collecting in a separate pan. The heavier slumgum and debris are left behind.

Key Advantage: Simultaneous Melting and Purification

The genius of the solar melter is its ability to purify as it melts. The gentle, consistent heat allows gravity to do the work of separation effectively. The resulting wax is often clean enough for use without further filtering.

Key Advantage: Recovering Trapped Honey

This method also excels at separating the residual honey from the wax. As the wax melts, the honey is released and will collect at the bottom of the catch pan, under the lighter wax, allowing you to recover both valuable products.

Alternative Method: Direct Heating

If you don't have a solar melter or live in a climate without consistent sun, direct heating is a viable alternative, though it requires more active management.

The Double Boiler Method

Never heat beeswax directly over a flame. Beeswax is flammable and scorches easily. The safest way to melt it is in a double boiler.

Place your wax in a dedicated pot, and then place that pot inside a larger pot filled with a few inches of water. Heating the water gently and evenly melts the wax without risk of scorching or fire.

Using Water for Purification

To clean wax using this method, you can add water directly to the pot with the raw comb. As you heat the mixture, the wax melts and floats on top.

Once melted, you can pour the entire mixture through a filter (like cheesecloth or a paint strainer) into a bucket. As it cools, the wax will solidify into a clean disk on top of the dirty water, which can then be discarded.

Understanding the Trade-offs

Choosing a method depends on balancing simplicity, wax quality, speed, and safety.

Solar Melter: Simplicity vs. Speed

The primary trade-off is time. A solar melter is slow and completely dependent on sunny, warm weather. It is not an on-demand solution and is less practical for beekeepers with very large quantities of wax to process quickly.

Direct Heat: Control vs. Risk

The double boiler method is much faster and can be done anytime, regardless of the weather.

However, it requires constant supervision. Overheating the wax can darken it and introduce a burnt smell, reducing its quality. You also introduce the risk of a messy spill or, if done improperly, a fire.

Making the Right Choice for Your Goal

Your choice of method should align with your scale of operation and priorities.

- If your primary focus is simplicity and high-quality wax: The solar wax melter is the undisputed best choice for most hobbyist beekeepers.

- If your primary focus is speed and processing large volumes: The direct heat double boiler method (using water for separation) is more effective, but you must prioritize safety.

- If your primary focus is recovering maximum honey from cappings: Let your cappings drain in a strainer for 24 hours before melting them with any method.

Ultimately, processing your own wax transforms a raw byproduct of your hive into a clean and valuable resource.

Summary Table:

| Method | Best For | Key Advantage | Main Consideration |

|---|---|---|---|

| Solar Wax Melter | Hobbyist Beekeepers | Passive purification & honey recovery | Requires sunny weather; slower process |

| Double Boiler | Large Volumes / Speed | Fast, on-demand melting | Requires active supervision; fire risk |

Upgrade Your Beekeeping Operation with HONESTBEE

Processing wax efficiently is just one part of a successful, productive apiary. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the high-quality, durable supplies needed to scale their operations.

We understand the demands of commercial beekeeping. Let us help you streamline your workflow with our wholesale-focused offerings.

Contact HONESTBEE today to discuss your equipment needs and wholesale pricing.

Visual Guide

Related Products

- Beeswax Melter for Candle Making Honey Bee Wax Melter

- Professional Stainless Steel Wax Melter for Beekeeping and Crafts

- Steam Beeswax Melter Wax Warmer for Wax Processing

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

People Also Ask

- What happens to beeswax if it is heated beyond 170F? Prevent Irreversible Quality Loss and Darkening

- What is the flashpoint of beeswax? Essential Safety and Quality Tips for Beekeepers

- What makes polyurethane foam environmentally friendly? The Surprising Benefits of a Durable, Inert Material

- What are the features of industrial wax melters? Unlock Precision Purity for Commercial Beeswax Production

- What are the main types of wax melters? Choose the Right Heating Method for Your Needs