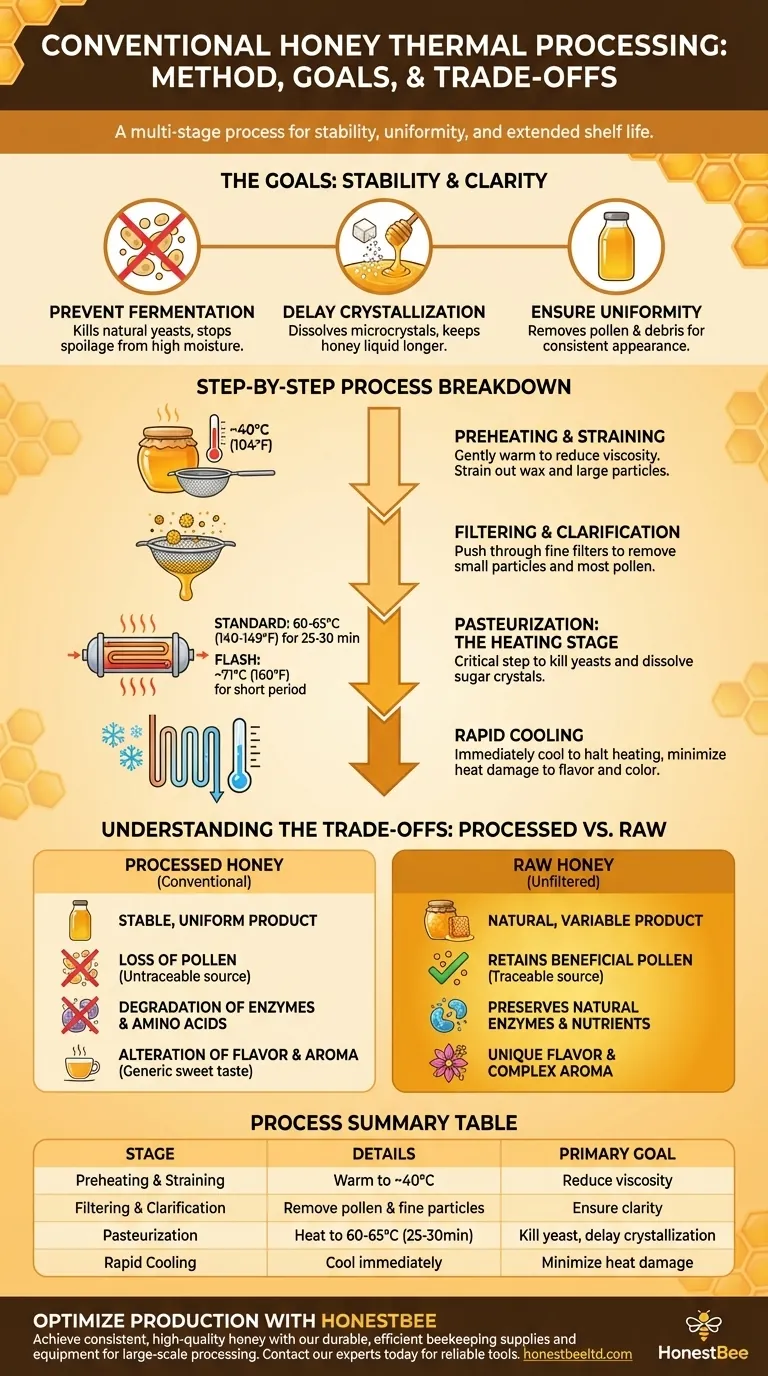

In short, the conventional thermal processing of honey is a multi-stage method designed to increase shelf life and ensure a uniform, clear product. The process involves preheating honey to around 40°C to make it less viscous, followed by straining and fine filtering, heating it to 60-65°C for about 30 minutes to pasteurize it, and finally, rapidly cooling it down.

Conventional processing fundamentally changes honey's natural state. It is a trade-off that prioritizes commercial stability—preventing fermentation and crystallization—at the expense of the unique enzymes, pollen, and flavor profiles found in raw honey.

The Goals of Conventional Honey Processing

To understand the method, you must first understand the commercial objectives. The primary goals are not to improve the honey but to make it more stable and consistent for the mass market.

Preventing Fermentation

Raw honey contains natural wild yeasts. If the honey's moisture content is too high (typically above 18%), these yeasts can trigger fermentation, spoiling the product. Pasteurization effectively kills these yeasts, ensuring a long and stable shelf life.

Delaying Crystallization

Crystallization is a natural process where glucose separates from the water in honey, forming solid crystals. While harmless, many consumers perceive it as a flaw. Heating dissolves any existing sugar microcrystals and, along with filtering, dramatically slows down this process, keeping the honey liquid for longer.

Ensuring Uniformity and Clarity

Filtering removes all suspended particles, including pollen, beeswax, and other microscopic debris. This results in the perfectly clear, golden liquid that many consumers expect, creating a visually consistent product from batch to batch.

A Step-by-Step Breakdown of the Process

Each stage of conventional processing is carefully calibrated to achieve the goals of stability and clarity.

Preheating and Straining

The honey is first gently warmed to approximately 40°C (104°F). This significantly reduces its viscosity, making it flow easily without causing significant heat damage. It is then passed through strainers to remove large particles like wax and bee parts.

Filtering and Clarification

After straining, the warmed honey is often pushed through a fine filter. This step removes much smaller particles, most notably the pollen grains. This is a key step that differentiates commercially processed honey from raw honey.

Pasteurization: The Heating Stage

This is the most critical thermal step. The filtered honey is heated indirectly, often in a tubular heat exchanger, to kill yeast cells and dissolve sugar crystals. Two common methods are:

- Standard Pasteurization: Heating to 60–65°C (140–149°F) for 25–30 minutes.

- Flash Pasteurization: A quicker, higher-temperature method, heating to around 71°C (160°F) for a very short period before immediate cooling.

Rapid Cooling

Immediately following pasteurization, the honey is cooled rapidly. This is crucial to halt the heating process and minimize heat-induced damage to the honey's flavor and color, helping to preserve what remains of its natural properties.

Understanding the Trade-offs: Processed vs. Raw Honey

The decision to thermally process honey is a decision to sacrifice certain natural qualities for commercial benefits.

Loss of Beneficial Pollen

Fine filtering removes nearly all pollen. Honey pollen is not only a source of nutrients but is also used by experts to verify the botanical and geographical origin of the honey. Its removal makes the honey's source untraceable.

Degradation of Enzymes and Amino Acids

The heat from pasteurization denatures, or breaks down, heat-sensitive enzymes like diastase and invertase, which are naturally present in raw honey and aid in digestion. Beneficial amino acids are also damaged during this stage.

Alteration of Flavor and Aroma

Heating and filtering strip away many of the delicate, volatile compounds that give raw honey its unique flavor and aroma. Processed honey tends to have a more one-dimensional, generic sweet taste compared to the complex profile of its raw counterpart.

Making the Right Choice for Your Goal

Understanding this process empowers you to choose the right honey based on your specific needs.

- If your primary focus is maximum shelf life and predictable consistency: Conventionally processed honey is engineered specifically for this purpose.

- If your primary focus is preserving natural health benefits, flavor, and traceability: Raw, unfiltered honey is the definitive choice, as it retains its natural enzymes, pollen, and complex taste.

Ultimately, choosing between raw and processed honey is a choice between a natural, variable product and a stable, uniform one.

Summary Table:

| Processing Stage | Key Details | Primary Goal |

|---|---|---|

| Preheating & Straining | Warm to ~40°C (104°F) | Reduce viscosity for easier handling |

| Filtering & Clarification | Remove pollen & fine particles | Ensure clarity and visual uniformity |

| Pasteurization | Heat to 60-65°C for 25-30 min | Kill yeast, prevent fermentation, delay crystallization |

| Rapid Cooling | Cool immediately after heating | Minimize heat damage to flavor and color |

Optimize Your Honey Production with HONESTBEE

As a commercial apiary or beekeeping equipment distributor, achieving consistent, high-quality honey is your priority. The conventional thermal processing method is key to ensuring product stability and meeting market demands for clarity and long shelf life.

HONESTBEE supplies the durable, efficient beekeeping supplies and equipment you need to implement this process effectively. From precise heating systems to filtering equipment, our wholesale-focused operations provide the reliable tools for large-scale production.

Ready to enhance your honey processing efficiency and product quality? Contact our experts today to discuss your specific needs and discover how HONESTBEE can support your commercial success.

Visual Guide

Related Products

- Economy Honey Homogenizer Mixer and Melting Machine for Beekeeping

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What is the purpose of industrial-grade mixing and standardization equipment? Ensure Honey Consistency and Quality

- What is the technical advantage of using specialized mixing equipment for bee bread? Preserve Texture and Quality

- How does industrial-grade honey processing equipment manage honey state? Precision Systems for Quality Preservation

- Why are specialized mixers required for blending bee bread with honey? Preserve Quality and Texture

- What role does professional deep-processing mixing equipment play in the development of honey cream? Elevate Your Product