At its core, a honey extractor is a machine that uses centrifugal force to remove honey from a honeycomb. By spinning frames of honeycomb at high speed inside a drum, the extractor flings the liquid honey out of the wax cells, allowing it to collect at the bottom for collection. The most significant benefit of this method is that it leaves the delicate wax comb almost entirely intact.

The primary function of a honey extractor is not just to extract honey, but to do so sustainably. Its true value lies in preserving the honeycomb, which can be returned to the hive, saving the bees immense energy and boosting the colony's future productivity.

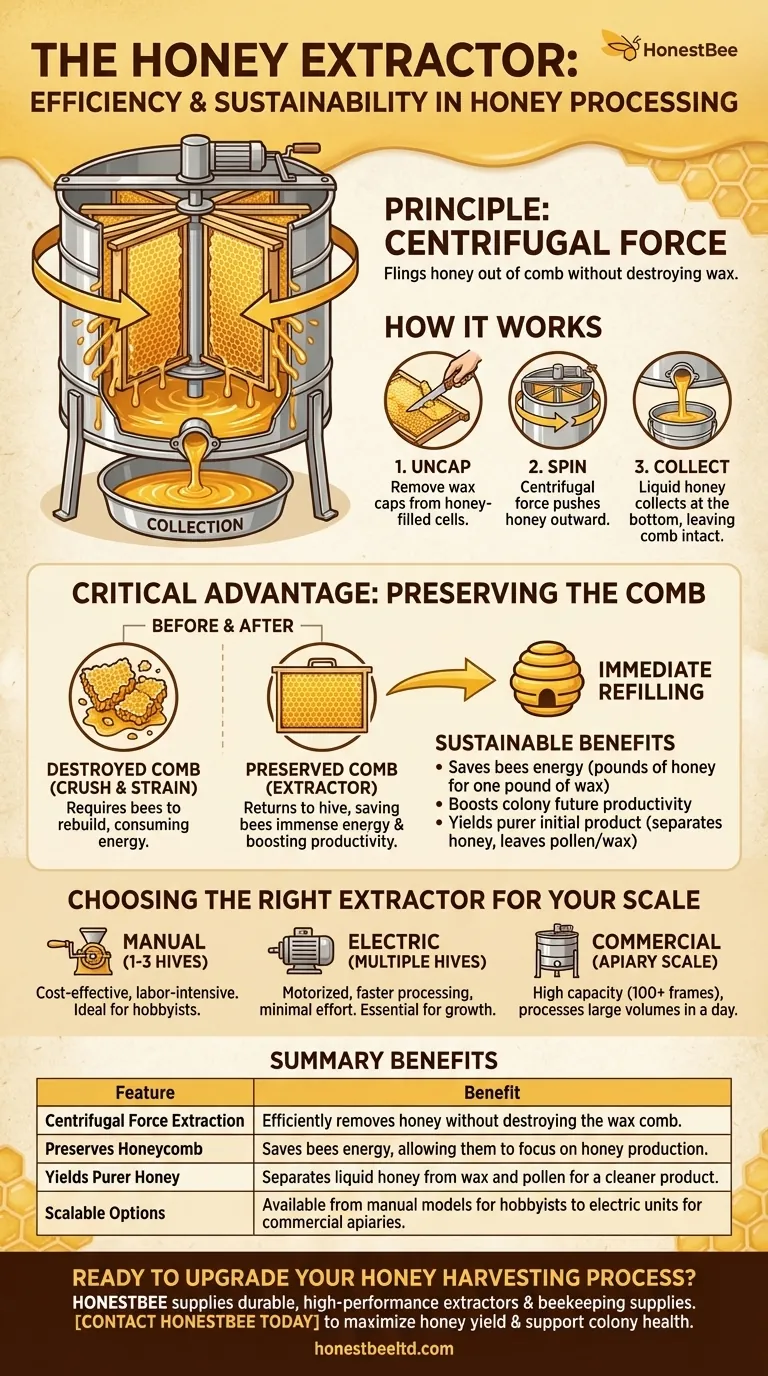

The Principle: Centrifugal Force Over Crushing

The honey extractor revolutionized honey harvesting by replacing older, more destructive methods with an efficient and reusable system. Understanding its mechanics reveals why it is an indispensable tool for modern beekeepers.

How an Extractor Works

The process is straightforward. First, the beekeeper uses a special knife or tool to slice off the thin wax caps that bees build to seal each honey-filled cell.

The uncapped frames are then placed into a basket inside the extractor's drum. As the basket spins, centrifugal force pushes the honey outward from the cells and onto the inner wall of the drum, where it drips down to a collection basin at the bottom.

The Critical Advantage: Preserving the Comb

The most important outcome of using an extractor is the preservation of the wax comb. Bees expend a tremendous amount of energy to build this structure; it is estimated they consume several pounds of honey to produce just one pound of wax.

By returning empty, intact combs to the hive, the beekeeper gives the colony a massive head start. The bees can immediately begin refilling the cells with nectar instead of spending weeks rebuilding the comb from scratch.

Ensuring Purity from the Start

This method also yields a purer initial product. Because it separates only the liquid honey, the comb's other contents—such as pollen and wax—remain in the frame. This contrasts sharply with methods that involve crushing the entire comb, which mixes all components together.

Choosing the Right Extractor for Your Scale

Extractors range from small, hand-cranked models to large, automated industrial units. The right choice depends entirely on the scale of your beekeeping operation.

Manual Extractors

A manual extractor is operated with a hand crank and is ideal for hobbyists with only one to three hives. They are cost-effective and simple to use, but the process is labor-intensive.

Electric Extractors

For anyone managing more than a few hives, an electric honey extractor is a necessity. These motorized units can process a greater number of frames far more quickly and with minimal physical effort, drastically improving the efficiency of a harvest.

Commercial-scale beekeepers may use electric extractors capable of holding over 100 frames at once, allowing them to process honey from entire apiaries in a single day.

Understanding the Trade-offs and Process Context

While the extractor is central to modern honey harvesting, it's important to understand its alternative and its place in the overall workflow.

The Alternative: Crush and Strain

Before extractors were common, the only method was "crush and strain." This involves scraping the entire honeycomb off its frame, crushing the wax and honey together, and then straining the mixture to separate the two.

The Downside of Crushing

The primary trade-off of the crush-and-strain method is the complete destruction of the comb. The bees are forced to rebuild it, consuming valuable time and resources that could have been used to produce more honey. This method also introduces more wax particles into the honey, often requiring more intensive filtration.

Where Extraction Fits in the Process

Extraction is a critical step, but not the final one. After the honey is collected from the extractor, it is typically left in a settling tank to allow air bubbles and larger wax particles to rise to the surface. It is then filtered through fine mesh to remove any remaining debris, resulting in the clean, clear honey ready for bottling.

Making the Right Choice for Your Operation

Selecting your extraction method comes down to balancing cost, efficiency, and your long-term goals as a beekeeper.

- If your primary focus is starting with 1-3 hives: A simple manual extractor or the crush-and-strain method is a viable and low-cost entry point.

- If your primary focus is efficiency for multiple hives: An electric honey extractor is essential for streamlining your harvest and handling a larger volume of frames.

- If your primary focus is sustainability and bee health: Using any type of extractor to preserve the comb is superior, as it supports a stronger and more productive colony.

Ultimately, the honey extractor transforms harvesting from a simple harvest into a sustainable cycle that benefits both the beekeeper and the bees.

Summary Table:

| Feature | Benefit |

|---|---|

| Centrifugal Force Extraction | Efficiently removes honey without destroying the wax comb. |

| Preserves Honeycomb | Saves bees energy, allowing them to focus on honey production. |

| Yields Purer Honey | Separates liquid honey from wax and pollen for a cleaner product. |

| Scalable Options | Available from manual models for hobbyists to electric units for commercial apiaries. |

Ready to upgrade your honey harvesting process?

For commercial apiaries and beekeeping equipment distributors, the right extraction equipment is key to operational efficiency and sustainable honey production. HONESTBEE supplies durable, high-performance honey extractors and a full range of beekeeping supplies through our wholesale-focused operations.

Contact HONESTBEE today to discuss how our equipment can help you maximize your honey yield and support the long-term health of your colonies.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- Why is advanced honey extraction and processing equipment essential? Boost Efficiency & Output

- What is the core function of a centrifugal honey extractor? Boost Your Apiary's Efficiency and Honey Yield

- How does honey extraction equipment maintain quality in complex climates? Ensure purity with precision processing.

- What is the best way to clean an electric honey extractor after use? A Guide to Purity & Longevity

- What are the advantages of stingless bee suction devices? Safe, Sustainable Harvesting for Commercial Success

- Why is the width of iron rings varied for radial honey extractor tilt? Optimize Your Harvest with Precise Engineering

- What is the significance of using extracted honey as a primary output indicator? Boosting Industrial Scaling

- Why is it necessary to weigh honeycombs before and after extraction? Maximize Your Honey Yield Accuracy