In short, the pressing method of honey extraction is a mechanical process where honey is forced out of the comb using a press. The combs are typically broken up, placed inside a press, and squeezed by a spindle or plate. The resulting honey is then gently warmed and strained to remove wax particles and other debris.

This traditional technique is valued for its ability to preserve the honey's delicate flavors and enzymes by avoiding high heat and agitation. However, its primary trade-off is the destruction of the honeycomb, making it less efficient than modern centrifugal methods.

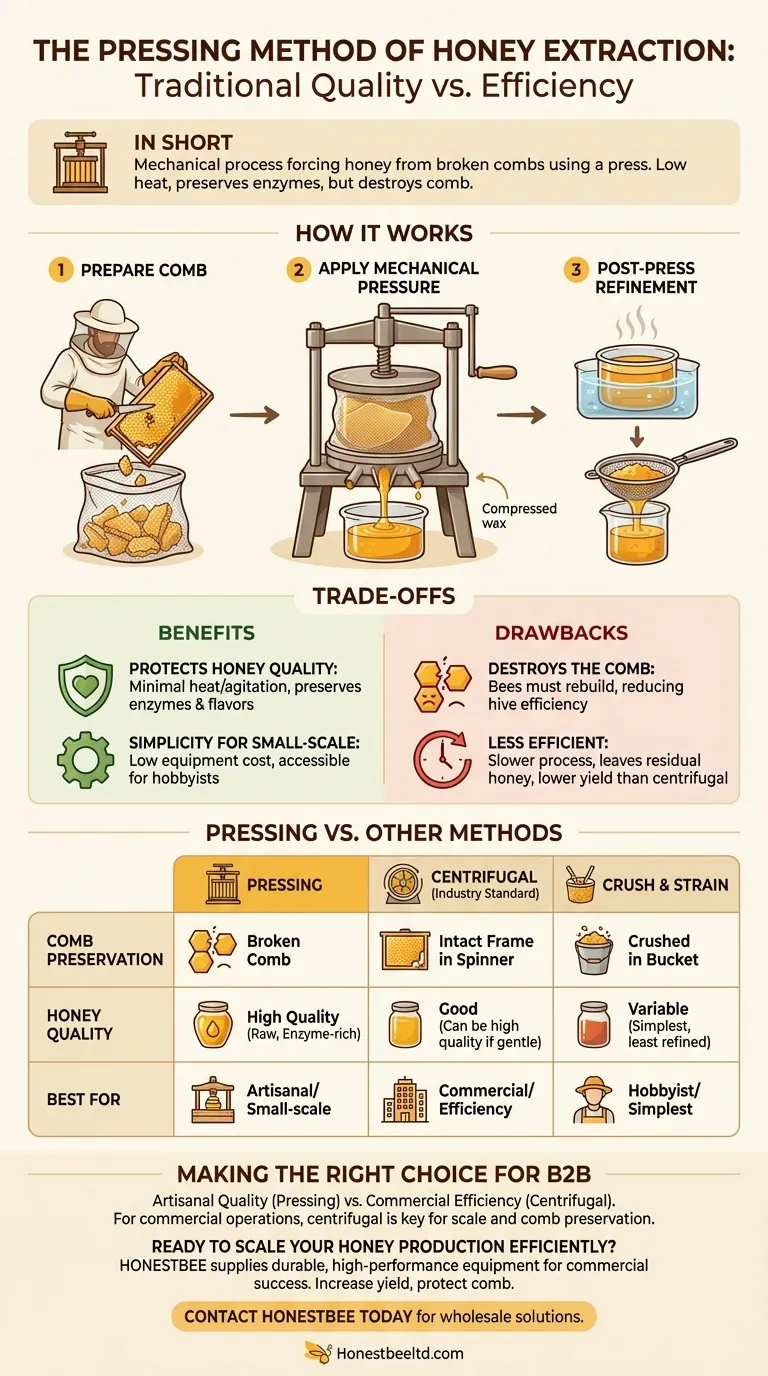

How the Pressing Method Works

Pressing is a straightforward, often manual, method for separating honey from its wax comb. It is one of the oldest forms of honey extraction.

Step 1: Preparing the Comb

First, the honey-filled combs are cut or scraped from their frames. They are then broken into smaller pieces and placed into a container, often a cloth or mesh bag, that will sit inside the press chamber.

Step 2: Applying Mechanical Pressure

A honey press, which typically uses a screw-and-plate mechanism, applies slow and steady pressure. As a spindle is turned, a plate presses down on the broken comb, squeezing the liquid honey out.

The honey flows out through spouts or perforations at the bottom of the press chamber, leaving the compressed beeswax and other solids behind.

Step 3: Post-Press Refinement

After being pressed, the honey is often gently warmed in a water bath. This is not for pasteurization, but simply to lower its viscosity, making it easier to strain.

The warm honey is then passed through a fine mesh filter or sieve. This step removes remaining bits of beeswax, propolis, and other hive debris, resulting in a clean, pure final product.

Understanding the Trade-offs of Pressing

While effective, the pressing method comes with distinct advantages and disadvantages that make it suitable for some beekeepers but not others.

Benefit: Protects Honey Quality

Gentle pressing minimizes heat and agitation. This helps protect the honey's delicate enzymes, natural yeast, pollen content, and unique aromatic compounds that can be damaged by aggressive industrial processing like flash pasteurization.

Benefit: Simplicity for Small-Scale Operations

A honey press is a relatively simple piece of equipment. This makes it an accessible option for hobbyists or small-scale apiarists who do not wish to invest in more complex and expensive centrifugal extractors.

Drawback: Destroys the Comb

This is the most significant disadvantage. Bees expend a tremendous amount of energy and resources to build wax comb. Pressing destroys the comb, forcing the bees to rebuild it from scratch, which reduces the hive's overall honey production efficiency for the next season.

Drawback: Less Efficient Than Extraction

Modern centrifugal extractors, which spin honey out of the frames, are much faster and yield more honey while preserving the comb. Pressing is a slower process and can leave a small amount of residual honey in the compressed wax.

How Pressing Compares to Other Methods

Understanding pressing requires placing it in context with other common extraction and processing techniques.

vs. Centrifugal Extraction

This is the modern industry standard. Frames are uncapped and placed in an extractor that spins them at high speed. Centrifugal force flings the honey out against the walls of the drum, leaving the comb intact and ready to be returned to the hive. It is highly efficient but requires more expensive equipment.

vs. Crush and Strain

This is the simplest method of all. The beekeeper manually crushes the comb in a bucket and pours the mixture of honey and wax into a sieve or cheesecloth. Gravity does the work of separating the honey. Pressing is essentially a more forceful and efficient version of the crush-and-strain method.

vs. Commercial Pasteurization

Pressed honey is often considered "raw" because it is not heated to high temperatures. In contrast, mass-market honey is often flash pasteurized at over 160°F (71°C) to kill yeast and then ultra-filtered to remove all particles, including pollen. This extends shelf life but also denatures beneficial enzymes and removes the pollen that gives honey its unique character.

Making the Right Choice for Your Goal

The best extraction method depends entirely on your priorities as a beekeeper or consumer.

- If your primary focus is hive productivity and efficiency: Centrifugal extraction is the superior choice because it preserves the valuable beeswax comb for reuse.

- If your primary focus is small-scale, traditional production: Pressing is an excellent method that produces high-quality, raw honey without a major investment in equipment.

- If your primary focus is consuming the most natural product: Look for honey labeled as "pressed" or "raw and unfiltered," as these methods retain the most pollen, enzymes, and delicate flavors.

Ultimately, the extraction technique directly shapes the character, quality, and composition of the final honey.

Summary Table:

| Aspect | Pressing Method | Centrifugal Extraction |

|---|---|---|

| Comb Preservation | Destroys the comb | Preserves the comb for reuse |

| Honey Quality | Excellent; preserves enzymes & pollen | Good; can be high-quality if handled gently |

| Equipment Cost | Low; suitable for small-scale | Higher; requires investment |

| Best For | Hobbyists, small-scale, raw honey producers | Commercial apiaries, efficiency-focused beekeepers |

Ready to Scale Your Honey Production Efficiently?

As a commercial apiary or beekeeping equipment distributor, maximizing hive productivity is your priority. While the pressing method has its place for artisanal quality, modern centrifugal extraction is key for commercial-scale efficiency and comb preservation.

HONESTBEE supplies the durable, high-performance beekeeping equipment you need to succeed. We provide wholesale-focused solutions for commercial operations, helping you increase yield and protect your valuable beeswax comb.

Contact HONESTBEE today to discuss equipment solutions tailored to your commercial beekeeping goals.

Visual Guide

Related Products

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

People Also Ask

- What is the best time of year to separate beeswax from honey? Optimize Your Harvest for Maximum Yield

- What materials are needed to construct a basic manual honey press? DIY Guide for Efficient Extraction

- What are the steps for using a bucket honey press? Master Efficient Wax and Honey Separation

- What is a Honey Press and what are its alternative names? Discover the Best Manual Extraction Methods

- Why are honey presses indispensable for larger beekeeping operations? Scale Your Harvest with High-Volume Processing

- What are the technical characteristics of the honey pressing method vs centrifugal extraction for Jatropha honey?

- What is an efficient method for processing large quantities of honey? Master Bulk Extraction with Metal Fruit Presses

- What are the multipurpose uses of a honey press? Boost Your Farm's Efficiency with One Tool