Extracting honey with a centrifuge is a mechanical process that uses centrifugal force to separate honey from the wax comb. The core steps involve removing the wax cappings from a frame of honey, placing the uncapped frame inside the extractor, and spinning it. The rotational force slings the honey out of the cells, where it collects at the bottom of the drum to be drained.

At its heart, the challenge of honey extraction is separating a liquid (honey) from a solid structure (the wax comb) without destroying the comb. A honey extractor is a purpose-built centrifuge that accomplishes this efficiently, allowing you to harvest the honey while preserving the valuable drawn comb for the bees to reuse.

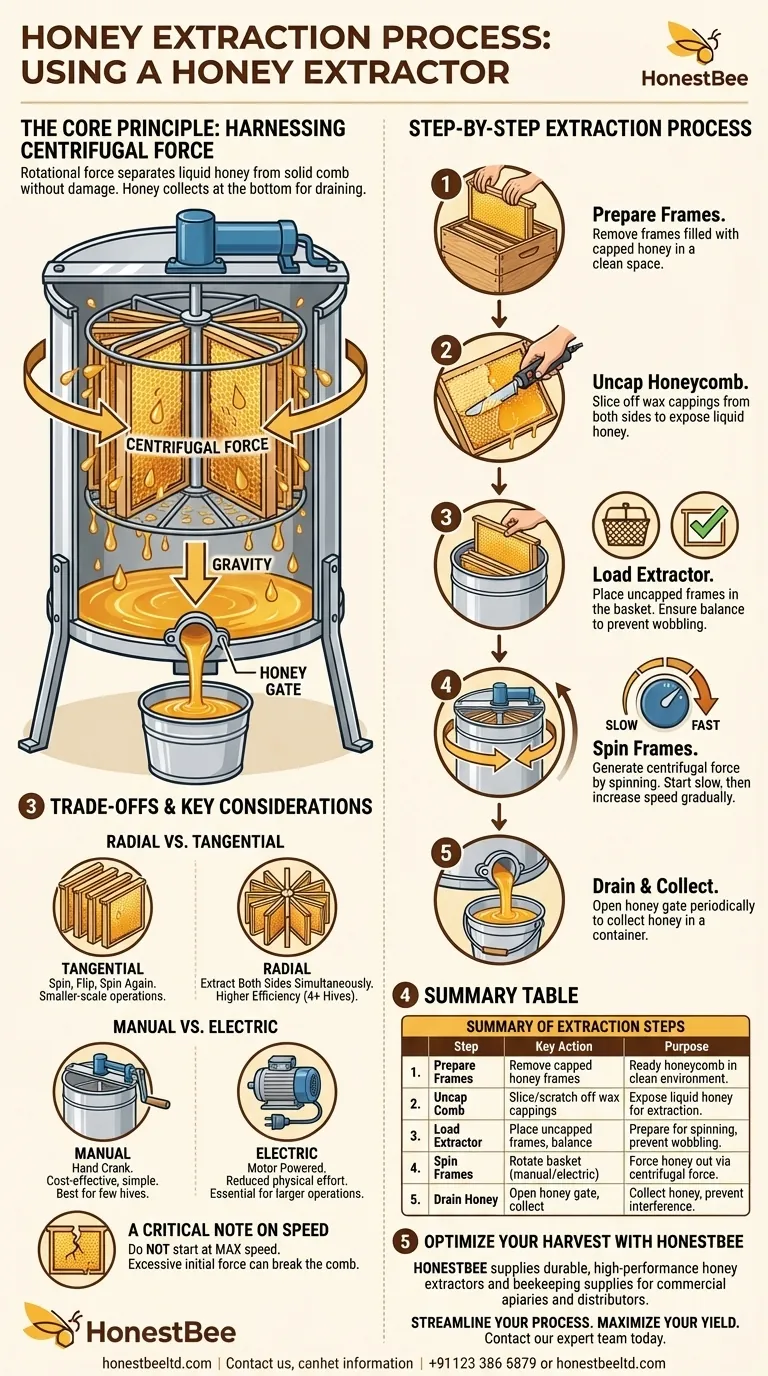

The Core Principle: Harnessing Centrifugal Force

A honey extractor is fundamentally a simple machine designed around a single physical principle. Understanding this is key to using the tool effectively.

How an Extractor Works

An extractor is a large drum containing a rotating basket or cage designed to hold honey frames. As this basket spins, it generates powerful centrifugal force.

This force pushes any loose material away from the center of rotation. Since the honey is a liquid and the comb is a solid, the honey is slung outward from the cells and onto the inner wall of the extractor.

Gravity then takes over, and the honey runs down the walls to the bottom of the drum. It pools there until it is drained through a tap, often called a honey gate.

The Importance of Uncapping First

Bees seal filled honey cells with a layer of beeswax, known as cappings. This wax cap protects the honey and keeps it at the proper moisture content.

Before extraction, this wax seal must be removed. If you place a capped frame in an extractor, the centrifugal force will not be strong enough to push the honey through the wax.

This uncapping is typically done with a heated electric knife, a serrated knife, or a specialized fork-like tool that scratches the cappings open.

The Step-by-Step Extraction Process

While specific models vary, the fundamental process for using any honey extractor remains consistent.

Step 1: Prepare Your Frames

Remove the frames filled with capped honey from your hive. It is best to work in a clean, enclosed space to prevent bees from being attracted to the exposed honey.

Step 2: Uncap the Honeycomb

Using your uncapping tool, carefully slice or scratch off the top layer of wax from both sides of the frame. This exposes the liquid honey within the cells.

Step 3: Load the Extractor

Place the uncapped frames into the basket of the extractor. Ensure the frames are balanced to prevent the extractor from wobbling violently when it starts spinning.

Step 4: Spin the Frames

Begin spinning the extractor. If it is a manual model, you will turn a hand crank. If it is electric, you will use a motor, often with variable speed control.

The spinning motion generates the centrifugal force needed to pull the honey from the cells.

Step 5: Drain and Collect the Honey

As the honey pools at the bottom of the extractor, open the honey gate to let it flow out into a food-grade bucket or container. It's important to drain the honey periodically so the level does not rise high enough to interfere with the spinning frames.

Understanding the Trade-offs and Key Considerations

Not all extractors are the same, and improper technique can cause problems. Understanding the differences and potential pitfalls is crucial for a successful harvest.

Radial vs. Tangential Extractors

Tangential extractors position the frames so one side of the comb faces outward. You must spin the frames, stop, flip them, and then spin again to extract honey from both sides. These are common for smaller-scale operations.

Radial extractors position the frames with the top bar facing outward, like spokes on a wheel. Centrifugal force extracts honey from both sides of the comb simultaneously, making them much more efficient for larger numbers of frames.

Manual vs. Electric Power

A manual extractor is powered by a hand crank. This is a cost-effective and simple option, perfect for beekeepers with only a few hives.

An electric extractor uses a motor to spin the basket. This significantly reduces physical effort and is almost essential for anyone managing more than a handful of hives.

A Critical Note on Spinning Speed

Do not start spinning at maximum speed. A sudden, high-speed rotation can cause the weight of the honey to break the delicate wax comb, especially in tangential extractors.

The best practice is to start slowly to sling out some of the honey, then gradually increase the speed to finish the job.

The Necessity of Post-Extraction Cleaning

Once you are finished, the extractor must be thoroughly cleaned with hot water. Any remaining honey will attract pests and can potentially harbor and spread bee diseases if not properly sanitized before the next use.

Making the Right Choice for Your Goal

Your choice of equipment and process depends entirely on the scale of your beekeeping operation.

- If your primary focus is a small-scale hobby (1-3 hives): A small, manual tangential extractor is the most cost-effective and practical solution for your needs.

- If your primary focus is efficiency for a growing apiary (4+ hives): Investing in a radial extractor will save you a significant amount of time and labor during harvest.

Ultimately, using a honey extractor is the most effective way to harvest honey while respecting the incredible work invested by your bees in building the comb.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Prepare Frames | Remove capped honey frames from the hive. | Ready the honeycomb for processing in a clean environment. |

| 2. Uncap Comb | Slice or scratch off the wax cappings from both sides of the frame. | Expose the liquid honey in the cells for extraction. |

| 3. Load Extractor | Place uncapped frames into the extractor basket, ensuring balance. | Prepare for spinning; imbalance can cause wobbling. |

| 4. Spin Frames | Rotate the basket manually or electrically to generate centrifugal force. | Force honey out of the cells and onto the extractor walls. |

| 5. Drain Honey | Open the honey gate to let honey flow into a collection container. | Collect the harvested honey without interfering with the spin. |

Ready to Optimize Your Honey Harvest?

Whether you manage a small apiary or are a large-scale distributor, the right equipment is crucial for efficiency and honey quality. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with durable, high-performance honey extractors and other essential beekeeping supplies through our wholesale-focused operations.

Let us help you streamline your process and maximize your yield.

Contact our expert team today to discuss your specific needs and discover how our products can benefit your operation.

Visual Guide

Related Products

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- What are some tips for using a honey extractor effectively? Maximize Your Honey Yield and Protect Your Comb

- Which type of extractor is more suitable for hobbyists or small-scale beekeepers? Find the Perfect Fit for Your Apiary

- How long does it take to extract honey with an extractor? Plan Your Harvest for Maximum Efficiency

- How many frames can different types of honey extractors hold? Maximize Your Harvest Efficiency

- What is the basic principle of the honey extractor? Harness Centrifugal Force for Efficient Harvesting