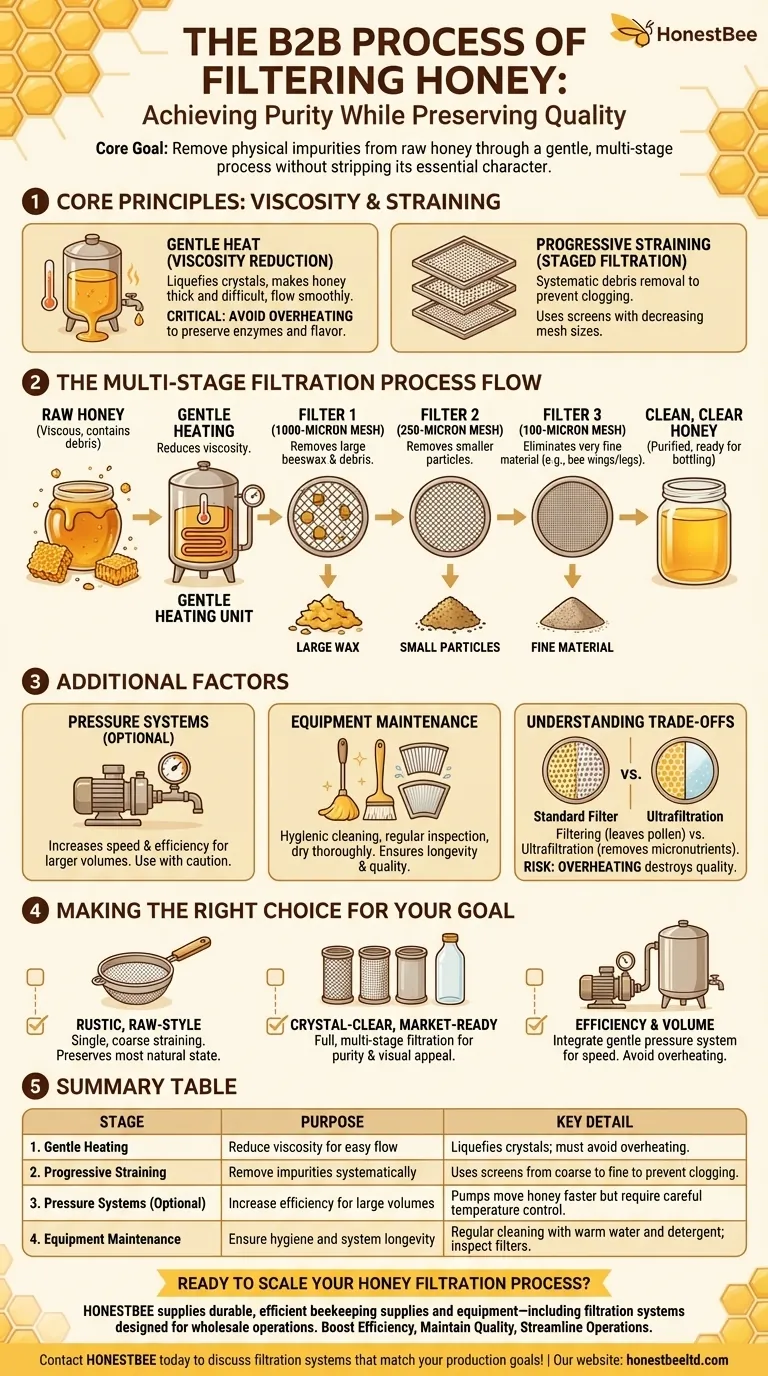

At its core, honey filtration is a multi-stage process designed to remove physical impurities from raw honey. It involves gently heating the honey to improve its flow and then passing it through a series of progressively finer mesh screens to systematically remove debris like beeswax, bee parts, and other contaminants, resulting in a clean and clear final product.

The central goal of honey filtration is not simply to clean the honey, but to achieve purity while preserving its natural quality. This is accomplished through a gentle, multi-step straining process that removes physical debris without stripping the honey of its essential character.

The Core Principles of Honey Filtration

The effectiveness of honey filtration relies on two key principles: reducing viscosity through gentle heat and removing impurities through staged straining.

Why Heat is a Critical First Step

Raw honey, especially if it has begun to crystallize, can be thick and difficult to work with. Gentle heating is applied to liquefy any crystals and reduce the honey's overall viscosity.

This makes the honey flow smoothly and easily through the filters, ensuring an efficient and consistent process without requiring excessive force.

The Logic of Progressive Straining

Instead of using a single, ultra-fine filter, the process uses a series of screens with decreasing mesh sizes. This staged approach prevents the finest filter from clogging immediately with large debris.

A typical setup might start with a 1000-micron mesh to catch large pieces of beeswax and debris. The honey then moves through a 250-micron mesh for smaller particles, followed by a 100-micron mesh to eliminate very fine material like bee wings or legs.

The Role of Pressure Systems

In some setups, especially larger commercial ones, pressure systems or pumps are used to move the honey through the filters. This increases the speed and efficiency of the operation, allowing larger volumes of honey to be processed more quickly.

Equipment and Maintenance

The process relies on specific equipment that must be properly maintained to ensure both honey quality and the system's longevity.

The Basic Filtration Setup

The essential equipment includes a tank for holding and gently heating the honey, a series of filters or strainers with varying mesh sizes, and a collection vessel for the purified honey. Pumps and bottling machines are often integrated into the system.

The Importance of Meticulous Maintenance

Proper equipment hygiene is non-negotiable. All components must be washed regularly with warm water and a mild detergent to prevent residue from building up and contaminating future batches.

Filters must be inspected for wear and tear and replaced when necessary. After cleaning, all parts should be dried thoroughly to prevent corrosion, and periodic checks for leaks or loose fittings will ensure the system runs efficiently.

Understanding the Trade-offs

While filtering is standard practice, the method and degree of filtration can impact the final product. It is critical to distinguish between standard filtering and more aggressive industrial techniques.

Filtering vs. Ultrafiltration

The process described here is filtering, which is designed to remove physical impurities while leaving beneficial microscopic components like pollen intact.

This should not be confused with ultrafiltration, a high-pressure industrial process that pushes honey through extremely fine filters. Ultrafiltration can remove pollen and other micronutrients, resulting in a product that is very clear and slow to crystallize but may lack the character of less-processed honey.

The Risk of Overheating

The application of heat must be carefully controlled. Gentle warming is beneficial, but overheating can destroy the delicate enzymes and subtle flavors that make honey unique. Maintaining the lowest possible temperature needed to ensure flow is key to preserving quality.

Making the Right Choice for Your Goal

Your approach to filtering should be dictated by the kind of final product you wish to create.

- If your primary focus is rustic, raw-style honey: A single, coarse straining process is likely sufficient to remove only the largest pieces of wax and debris, preserving the honey's most natural state.

- If your primary focus is a crystal-clear, market-ready product: Employing a full, multi-stage filtration with progressively finer screens is necessary to achieve the purity and visual appeal consumers expect.

- If your primary focus is efficiency and volume: Integrating a gentle pressure system can significantly speed up the process, but care must be taken to avoid overheating or damaging the honey.

Ultimately, mastering honey filtration is about balancing the goal of purity with the preservation of the honey's natural integrity.

Summary Table:

| Stage | Purpose | Key Detail |

|---|---|---|

| 1. Gentle Heating | Reduce viscosity for easy flow | Liquefies crystals; must avoid overheating to preserve enzymes and flavor. |

| 2. Progressive Straining | Remove impurities systematically | Uses screens from coarse (e.g., 1000-micron) to fine (e.g., 100-micron) to prevent clogging. |

| 3. Pressure Systems (Optional) | Increase efficiency for large volumes | Pumps move honey faster but require careful temperature control. |

| 4. Equipment Maintenance | Ensure hygiene and system longevity | Regular cleaning with warm water and detergent; inspect filters for wear. |

Ready to Scale Your Honey Filtration Process?

As a commercial apiary or beekeeping equipment distributor, achieving consistent, high-quality honey is key to your success. HONESTBEE supplies durable, efficient beekeeping supplies and equipment—including filtration systems designed for wholesale operations.

We help you:

- Boost Efficiency: Process large volumes quickly with reliable equipment.

- Maintain Quality: Preserve honey’s natural integrity while ensuring purity.

- Streamline Operations: From tanks to filters, get tailored solutions for your needs.

Contact HONESTBEE today to discuss filtration systems that match your production goals!

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Professional Thermostatic Conical Honey Melter

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Honeycomb Style Drip Free Honey Dispenser

People Also Ask

- What are the benefits of motorized honey extractors? Save Time & Labor in Your Apiary

- What are the main components of the honey vacuum thickener equipment? A Guide to Preserving Honey Quality

- What additional functions does a honey vacuum thickener have? Achieve a Stable, Commercial-Grade Product

- What steps should be followed when starting and stopping the vacuum pump in the honey vacuum thickener? Protect Your Honey & Equipment

- What are the benefits of a honey concentrator? Elevate Your Honey Quality and Market Value