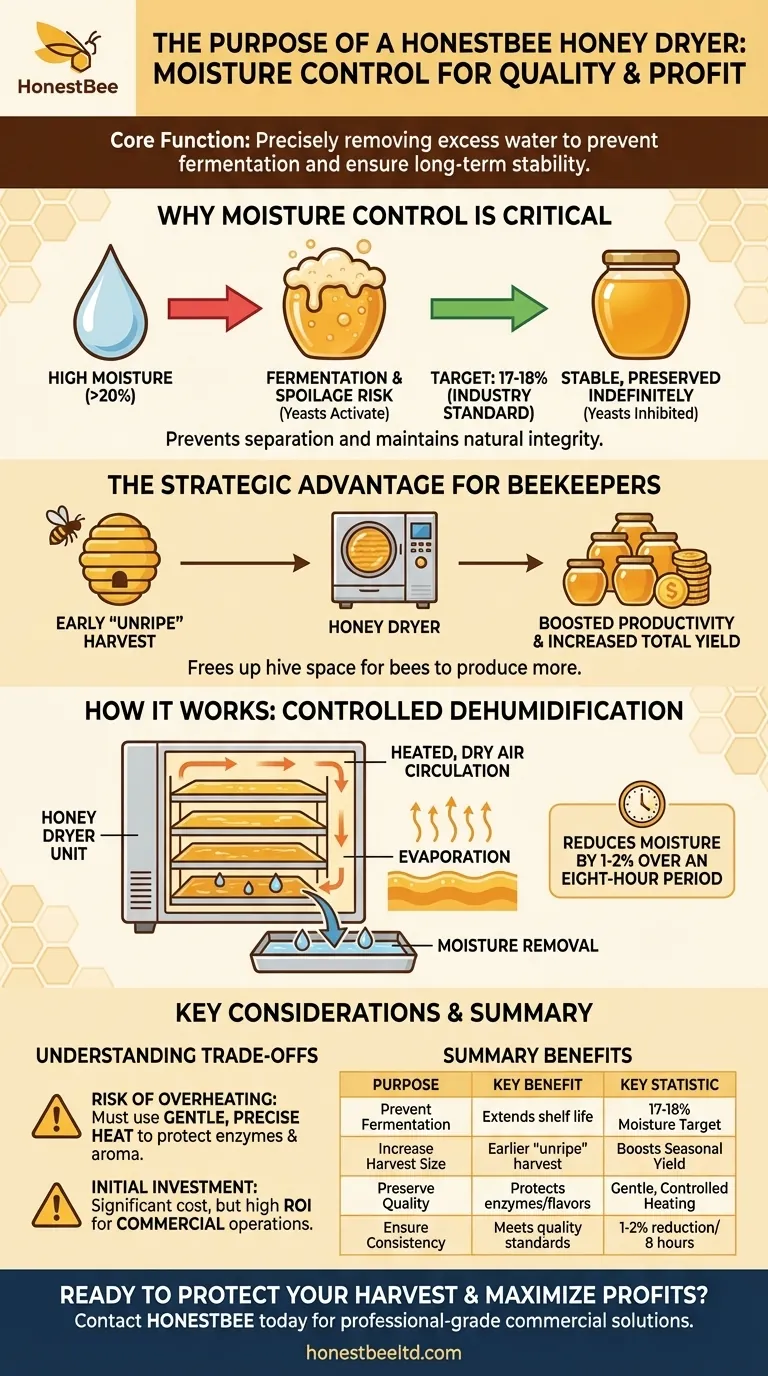

At its core, a honey dryer is a specialized piece of equipment designed for one primary function: removing excess water from honey. By precisely controlling the moisture content, it prevents fermentation and spoilage, ensuring the honey is stable for long-term storage and meets quality standards, which typically require a water content of 18% or less.

The central challenge in honey processing is that honey with high moisture content (above 20%) will inevitably ferment. A honey dryer solves this by creating a controlled environment to safely evaporate excess water, thereby protecting the honey's quality, extending its shelf life, and increasing a beekeeper's overall productivity.

Why Moisture Control is Critical for Honey

The water content of honey is the single most important factor determining its quality and stability. While bees work to dehydrate nectar in the hive, conditions like high humidity can leave the final product with too much moisture.

Preventing Fermentation and Spoilage

Honey contains natural yeasts. In honey with a water content above 20%, these yeasts can activate and begin to ferment the sugars, turning the honey sour and unusable.

Reducing the moisture level to the industry standard of 17-18% makes the honey too dense for yeast to thrive, effectively preserving it indefinitely.

Maintaining Honey's Natural Integrity

Excessive moisture can cause honey to separate into layers of different densities, harming its texture and appearance.

Properly dried honey remains homogenous and stable. A professional honey dryer uses gentle, controlled heating, which ensures that the delicate enzymes, flavors, and aromas are not damaged or boiled off in the process.

The Strategic Advantage for Beekeepers

Beyond simple preservation, a honey dryer is a powerful tool for improving the efficiency and output of a beekeeping operation.

Boosting Productivity and Harvest Size

Beekeepers can harvest honey earlier in the season, even if the bees haven't fully "capped" it (a sign of low moisture). This is known as harvesting "unripe" honey.

By drying this honey mechanically, the beekeeper frees up space in the hive for the bees to continue producing more honey, significantly increasing the total yield per season.

How the Dehumidification Works

The process is based on simple evaporation. The honey dryer circulates heated, dry air over the honey, which is typically spread out over a large surface area inside the machine.

This dry microclimate encourages water molecules to evaporate from the honey's surface. The moisture is then collected and removed, gradually reducing the honey's overall water content by about 1-2% over an eight-hour period.

Understanding the Trade-offs

While highly effective, the use of a honey dryer requires a careful balance. It is not simply about removing water, but doing so without compromising the honey's natural qualities.

The Risk of Overheating

Applying too much heat too quickly can destroy the beneficial enzymes in raw honey and drive off the volatile compounds that create its unique aroma and flavor.

Professional dryers are designed with precise temperature controls and double-walled construction to provide gentle, even heat that protects the honey's delicate profile.

The Initial Investment

A honey dryer represents a significant financial investment. For small-scale or hobbyist beekeepers, the cost may not be justified if their harvests are small enough to be managed by waiting for the bees to fully cure the honey in the hive.

However, for any commercial operation, the increased yield and guaranteed product quality often provide a rapid return on the investment.

Making the Right Choice for Your Goal

Deciding whether to invest in a honey dryer depends entirely on the scale and ambition of your beekeeping operation.

- If your primary focus is hobbyist beekeeping: You can likely rely on traditional methods, ensuring you only harvest fully capped frames where the bees have already lowered the moisture content.

- If your primary focus is commercial production: A honey dryer is an essential tool for maximizing your harvest, guaranteeing consistent quality, and insuring your product against spoilage.

- If your primary focus is producing premium, artisanal honey: A high-quality dryer gives you precise control over the final product, allowing you to preserve delicate flavors and achieve the perfect viscosity.

Ultimately, mastering moisture control is the key to transforming a good honey harvest into a consistently excellent and profitable product.

Summary Table:

| Purpose | Key Benefit | Key Statistic |

|---|---|---|

| Prevent Fermentation | Extends shelf life indefinitely | Reduces moisture to 17-18% |

| Increase Harvest Size | Enables earlier harvesting of 'unripe' honey | Can boost total seasonal yield |

| Preserve Quality | Protects delicate enzymes and flavors | Uses gentle, controlled heating |

| Ensure Consistency | Meets industry quality standards | Removes 1-2% moisture over 8 hours |

Ready to protect your harvest and maximize your profits?

For commercial apiaries and beekeeping equipment distributors, precise moisture control is not a luxury—it's a necessity for a stable, high-quality product. HONESTBEE supplies the professional-grade honey dryers and beekeeping equipment you need to guarantee quality, prevent spoilage, and significantly increase your yield.

Our wholesale-focused operations are designed to support your business's growth and efficiency.

Contact HONESTBEE today to discuss your commercial beekeeping supply needs and discover the right honey drying solution for your operation.

Visual Guide

Related Products

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- Easy Use Manual Stainless Steel Honey Press for Honey Comb

- Stainless Steel Triangle Support Honey Strainer and Filters

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

People Also Ask

- What is the main purpose of professional dehumidifiers in honey production? Achieve Premium Quality and Stability

- What is the primary purpose of using industrial dehumidifiers in the pretreatment of stingless bee pot-pollen?

- What happens to honey's viscosity with increased humidity? The Critical Link to Quality & Spoilage

- What is the role of industrial spray drying equipment in the deep processing of stingless bee honey?

- What are some tips for preventing excess moisture in honey during harvesting? Essential Steps for a Stable Harvest

- What are the advantages of a condensation honey dryer? Boost Quality & Yield for Your Apiary

- How to reduce moisture level in honey? Preserve Quality and Prevent Fermentation

- What is the humidity extraction capability of the honey dryer? Achieve Perfect Honey Moisture Control