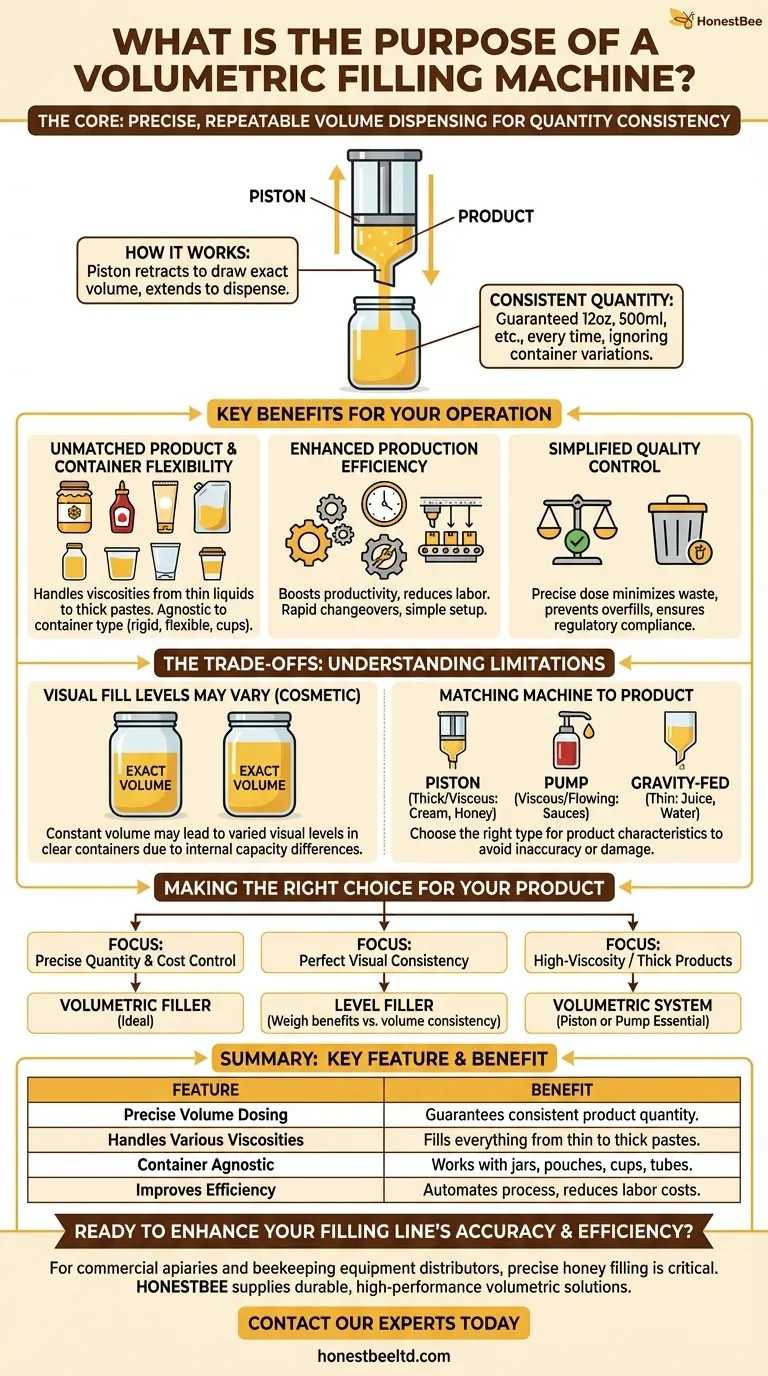

At its core, the purpose of a volumetric filling machine is to dispense a precise, repeatable volume of a product into a container. This method ensures that every package contains the exact same amount of product, a critical factor for products sold by weight or volume, such as honey, sauces, or pharmaceuticals. Its primary function is to guarantee quantity consistency, regardless of minor variations in container shape or size.

The central advantage of a volumetric filler is its commitment to product quantity over visual fill-level. This makes it the definitive choice for industries where precise dosing is essential for regulatory compliance, cost control, and consumer trust.

The Core Principle: Volume Over Level

The defining characteristic of a volumetric filler is its method of measurement. Unlike level fillers that fill to a certain height in a container, volumetric systems dispense a pre-measured amount.

How Volumetric Filling Works

The most common mechanism is a piston filler. The machine uses a piston that retracts within a cylinder to draw in a specific volume of product from a hopper. The piston then extends, dispensing that exact volume into the waiting container.

This process is purely mechanical and based on the displacement of the piston, ensuring a high degree of accuracy and repeatability with every cycle.

The Advantage of Consistent Quantity

This focus on volume is critical. If your containers have slight manufacturing imperfections (e.g., thicker glass at the bottom), a level filler would result in inconsistent product amounts.

A volumetric filler ignores these container variations. It delivers the specified 12 ounces or 500 milliliters every single time, which is essential for maintaining profitability and meeting labeling regulations.

Key Benefits for Your Operation

Adopting volumetric filling technology translates directly into measurable improvements in production flexibility, efficiency, and quality.

Unmatched Product and Container Flexibility

Volumetric fillers are exceptionally versatile. They can handle a vast range of product viscosities, from thin liquids like juice to thick pastes like lotion or even honey.

They are also agnostic to container type. Whether you are filling rigid jars, flexible pouches, yogurt cups, or toothpaste tubes, the machine delivers the same accurate volume.

Enhanced Production Efficiency

Automating the filling process with a volumetric machine significantly boosts productivity and reduces manual labor costs. Both semi-automatic and fully automatic models offer simple setup and operation, allowing for rapid changeovers between different products or container sizes.

Simplified Quality Control

Because the machine guarantees a precise dose, the need for manual weight checks and adjustments is drastically reduced. This built-in accuracy minimizes product waste, prevents costly overfills, and ensures every customer receives exactly what they paid for.

Understanding the Trade-offs

While highly effective, volumetric fillers are not the solution for every single application. Understanding their limitations is key to making an informed decision.

Visual Fill Levels May Vary

The primary trade-off is cosmetic. Because the machine dispenses a constant volume, any variation in the internal capacity of your containers will result in slightly different visual fill heights.

For products in clear packaging where a perfectly uniform shelf appearance is paramount, this can be a drawback. In these cases, a level filler might be considered, but you sacrifice volume consistency.

Matching the Machine to the Product

"Volumetric filler" is a category, not a single machine. The main types—piston, pump, and gravity-fed—are each suited for different product characteristics.

A highly viscous product like cream requires a powerful piston or pump filler, whereas a thin, free-flowing liquid might work well with a simpler gravity-fed system. Choosing the wrong type can lead to inaccurate fills or damage to the product.

Making the Right Choice for Your Product

To determine if a volumetric filler is the correct tool for your goal, evaluate your primary operational priority.

- If your primary focus is precise quantity and cost control: A volumetric filler is the ideal solution, guaranteeing you meet label claims and minimize product giveaway.

- If your primary focus is perfect visual consistency in clear containers: You may need to weigh the benefits of a level filler, but be prepared for potential variations in net weight.

- If your primary focus is filling high-viscosity or thick products: A volumetric system, specifically a piston or pump filler, is essential for accurate and reliable dispensing.

Ultimately, selecting the right filling technology is a foundational decision that impacts your product quality, operational efficiency, and profitability.

Summary Table:

| Feature | Benefit |

|---|---|

| Precise Volume Dosing | Guarantees consistent product quantity for labeling and cost control. |

| Handles Various Viscosities | Fills everything from thin liquids to thick pastes like honey. |

| Container Agnostic | Works with jars, pouches, cups, and tubes without adjustment. |

| Improves Efficiency | Automates process, reduces labor, and allows for quick changeovers. |

Ready to enhance your filling line's accuracy and efficiency?

For commercial apiaries and beekeeping equipment distributors, precise honey filling is critical for profitability and brand trust. HONESTBEE supplies the durable, high-performance volumetric filling equipment you need to ensure every jar contains the exact amount promised.

Contact our experts today to discuss the right volumetric solution for your operation and see how we can help you minimize waste and maximize output.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Fully Automatic Honey Filling Packaging Machine for Processing Line

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

People Also Ask

- How does industrial honey-filling machinery support Robinia pseudoacacia stands? Maximize Your Acacia Honey Yield

- What is the function of the HMI touch screen in a honey stick machine? Unlock Centralized Control for High-Volume Production

- Why is the use of high-precision honey filling machines necessary? Secure Your Stingless Bee Honey Profits

- What criteria should be evaluated when selecting a honey filling machine? Top Tips for Maximum Efficiency

- What problems are addressed by using specialized honey filtration and filling equipment? Scaling Melipona Honey Quality

- How do automated honey filling machines assist beekeeping cooperatives? Scale Your Honey Retail Distribution Today

- What role do high-precision automatic filling machines play in honey packaging? Ensure Purity and Weight Consistency

- What types of honey filling machines are available? Find the Perfect System for Your Apiary