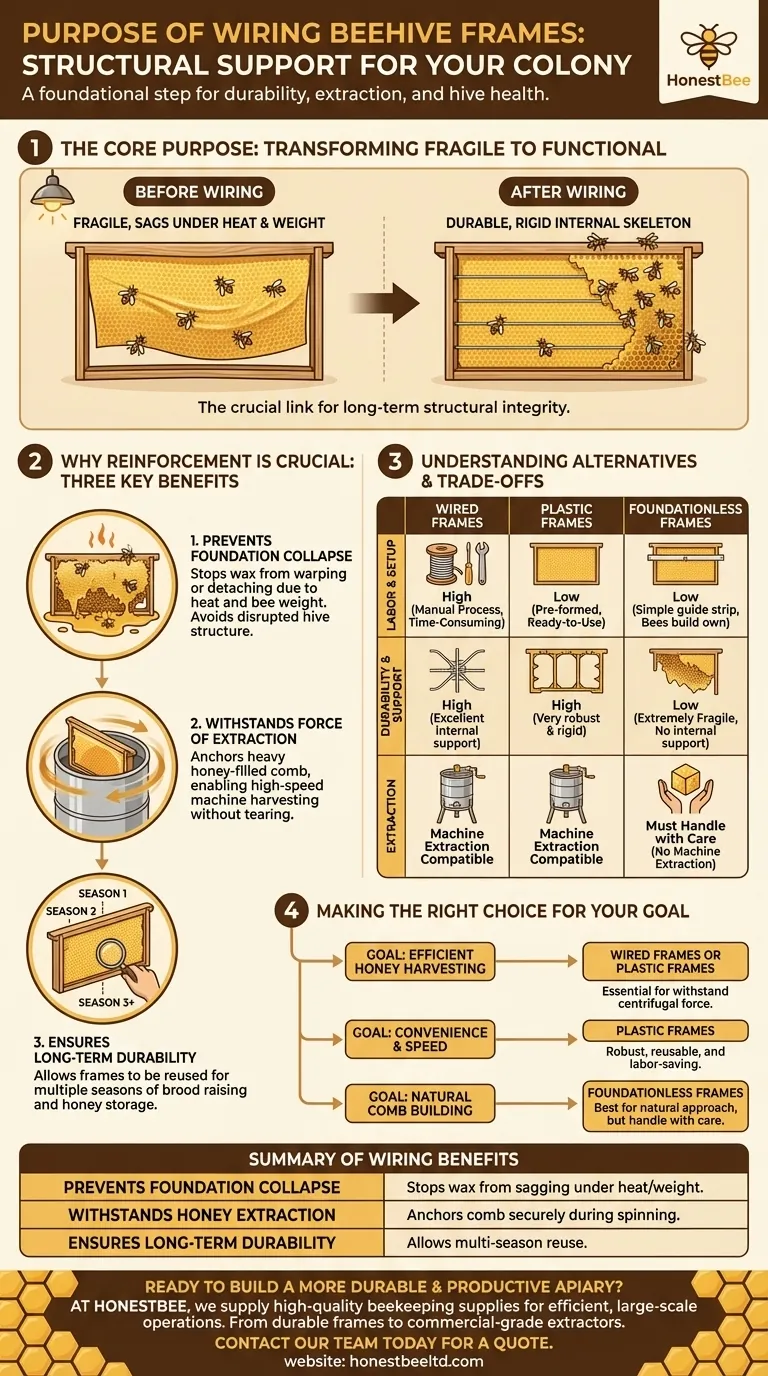

Wiring a beehive frame is a foundational step in preparing equipment for a new colony. The primary purpose of the wires is to provide a rigid internal skeleton for the sheet of wax foundation. This reinforcement prevents the foundation from sagging under heat and weight, keeps the finished honeycomb from breaking apart during honey extraction, and ensures the comb remains securely attached to the frame for years of use.

At its core, wiring transforms a fragile sheet of wax into a durable, functional structure. It is the crucial link between the wooden frame and the delicate comb, ensuring the integrity of the hive's most vital component from initial construction to final harvest.

Why Structural Reinforcement is Crucial

A sheet of wax foundation on its own is surprisingly delicate. The internal environment of a beehive is warm and humid, which softens the wax. Without support, problems arise quickly.

Preventing Foundation Collapse

The weight of the bees themselves, as they begin to work on the foundation, can cause an unsupported sheet to warp, sag, or even detach completely from the frame.

This forces the bees to waste precious time and resources repairing the damage or building "burr comb" in undesirable places, disrupting the orderly structure of the hive.

Withstanding the Force of Extraction

The most critical function of wiring becomes apparent during honey harvest. A frame full of honey is heavy, and the comb is brittle.

To extract the honey, beekeepers place frames in a centrifugal extractor, which spins them at high speed. The immense force generated would easily tear the heavy comb from the frame if it were not held in place by the embedded wires. Wiring is what makes machine extraction possible.

Ensuring Long-Term Durability

Beehive frames are not single-use items. A well-built comb will be used by the colony for many seasons to raise brood and store honey.

Wiring helps the comb withstand the stress of repeated handling during hive inspections, seasonal temperature changes, and multiple extraction cycles. It anchors the comb securely, preventing it from breaking away from the wood as it ages.

Understanding the Trade-offs and Alternatives

While wiring is a standard practice, it requires time and effort. Understanding the alternatives helps you decide if it's the right choice for your operation.

The Labor of Wiring

Wiring is a manual process that adds to the initial setup time for your equipment. It requires tools like a spool of wire, eyelets to protect the wood, and a way to heat and embed the wire into the wax foundation. For large-scale beekeepers, this labor is a significant consideration.

Plastic Frames: The All-in-One Solution

The most common alternative is the molded plastic frame. These frames come as a single piece with the "foundation" pattern already integrated into the rigid plastic surface.

This design completely eliminates the need for wiring, as the plastic itself provides all the necessary structural support. Beekeepers often coat them with a thin layer of beeswax to encourage the bees to accept and build on them.

Foundationless Frames: A Natural Approach

Some beekeepers prefer to let bees build their own comb from scratch without any foundation. These "foundationless" frames use only a small guide strip of wood or wax at the top.

While this appeals to those practicing natural beekeeping, the resulting comb is extremely fragile and has no internal support. It cannot be put through a centrifugal extractor and must be handled with extreme care.

Making the Right Choice for Your Goal

Your decision to wire frames—or not—should be based directly on your beekeeping objectives.

- If your primary focus is efficient honey harvesting: Wiring your frames or using solid plastic frames is non-negotiable to withstand the forces of a centrifugal extractor.

- If your primary focus is convenience and setup speed: Molded plastic frames offer a robust, reusable, and labor-saving alternative that requires no wiring.

- If your primary focus is natural comb building: Foundationless frames are the best choice, but you must be prepared to forgo machine extraction and handle the combs with extreme care.

Ultimately, providing proper structural support for your combs protects your investment in equipment and honors the immense work of your bees.

Summary Table:

| Purpose of Wiring | Key Benefit |

|---|---|

| Prevents Foundation Collapse | Stops wax from sagging under heat and bee weight. |

| Withstands Honey Extraction | Anchors comb securely during centrifugal spinning. |

| Ensures Long-Term Durability | Allows frames to be reused for multiple seasons. |

Ready to build a more durable and productive apiary?

At HONESTBEE, we supply the high-quality beekeeping supplies and equipment that commercial apiaries and distributors rely on for efficient, large-scale operations. From durable frames and wiring kits to commercial-grade extractors, our wholesale-focused solutions are designed to maximize your harvest and protect your investment.

Let's discuss your specific needs. Contact our team today to get a quote or learn more about our product range.

Visual Guide

Related Products

- HONESTBEE Professional Frame Wiring Board and Jig

- Plastic Bee Frame Beekeeping Hive Frames for Wholesale

- HONESTBEE Wired and Assembled Wooden Bee Frames Foundation for a Thriving Hive

- Assembled Wooden Bee Frames with Beeswax Foundation Ready to Use by HONESTBEE

- 7 x Auto Bee Flow Hive Frames Plastic Beekeeping Hive Box Supplies

People Also Ask

- What should be done to the sidebars if wiring the frames? A Guide to Drilling Holes for Maximum Frame Strength

- What feature of the frame wiring jig helps maintain wire tightness? The Essential Tensioner Explained

- What is the advantage of a bee frame wiring jig? Drastically Speed Up Hive Preparation

- What tools are needed to wire a beehive frame? Essential Equipment for Durable Frame Construction

- What is the purpose of the frame wiring jig? Speed Up Bee Frame Wiring in Under 90 Seconds