The primary role of a honey extractor is to remove honey from the comb using centrifugal force. This mechanical process allows beekeepers to harvest honey without destroying the delicate beeswax comb, enabling the bees to refill it immediately. This makes honey production significantly more efficient and sustainable for the colony.

A honey extractor represents a fundamental choice for a beekeeper: it is an investment in long-term efficiency. By preserving the honeycomb, you save your bees immense energy, which they can then redirect into producing more honey.

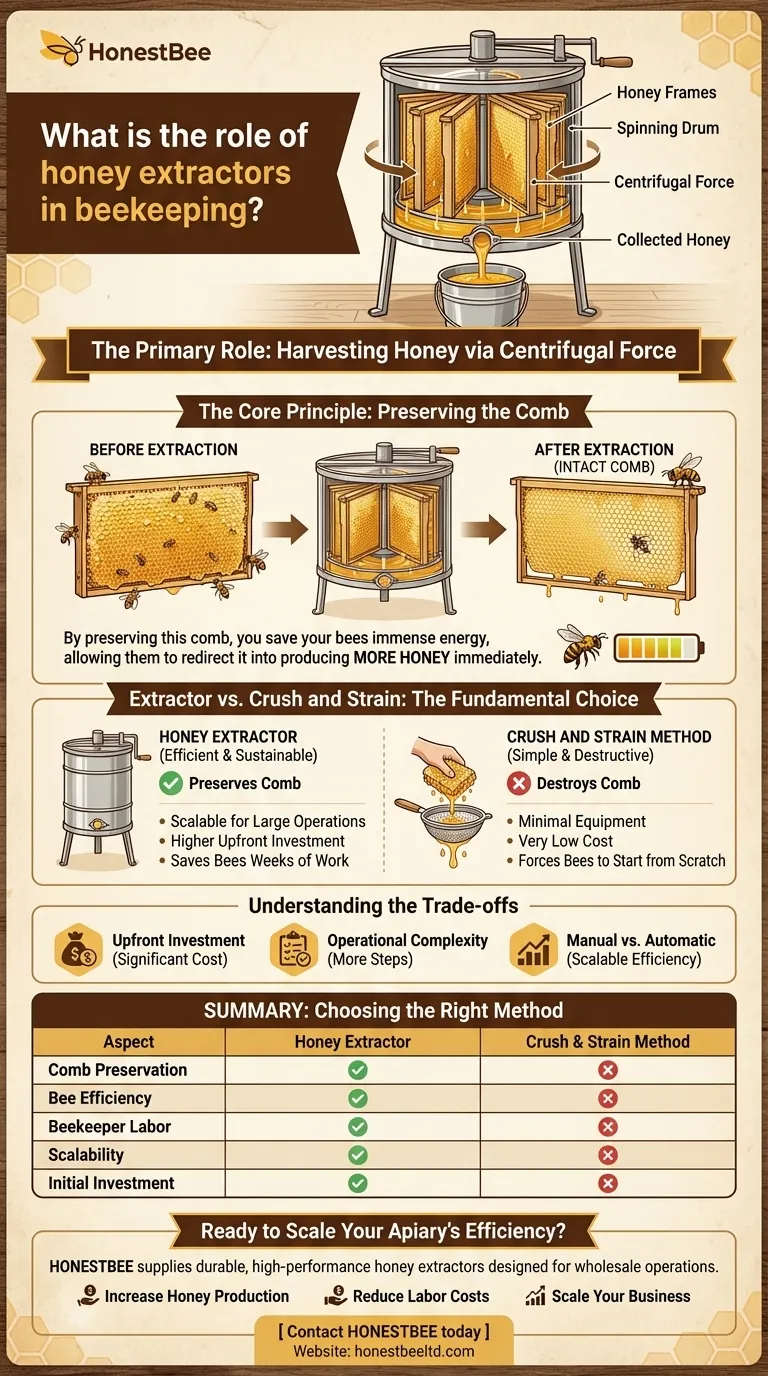

The Core Principle: Preserving the Comb

The true value of a honey extractor isn't just in removing honey, but in what it leaves behind. Understanding the importance of intact comb is central to understanding the extractor's role.

How an Extractor Works

An extractor is essentially a drum that holds honey frames. When the mechanism is spun, either by a hand crank or an electric motor, it generates powerful centrifugal force. This force slings the liquid honey out of the thousands of individual wax cells and onto the inner wall of the drum, where it drips down and collects at the bottom.

The Value of Undamaged Comb

Bees expend a tremendous amount of energy and resources to build beeswax comb. It is the essential structure of their hive for raising young and storing food.

By preserving this comb, you give the bees a massive head start on the next honey flow. Instead of spending weeks rebuilding their pantry, they can immediately begin foraging and storing new nectar, leading to a much larger potential honey harvest.

Extractor vs. Crush and Strain: The Fundamental Choice

For a new beekeeper, the decision to use an extractor is one of the first major equipment choices they will face. The alternative is a simpler, more traditional method.

The Crush and Strain Method

The most basic way to harvest honey is to crush the entire comb, wax and all. This mixture is then poured through strainers or cheesecloth to separate the liquid honey from the pieces of wax.

This method requires minimal specialized equipment, making it very accessible for hobbyists. However, it completely destroys the comb, forcing the bees to start from scratch.

Efficiency at Scale

While crush and strain works for one or two hives, it becomes highly inefficient for larger operations. The honey extractor is a crucial tool for any beekeeper focused on productivity.

It saves the bees weeks of work and dramatically reduces the time and labor the beekeeper spends on harvesting. This is why it is considered standard equipment for any medium to large-scale apiary.

Understanding the Trade-offs

Choosing to use a honey extractor is not without its considerations. It's a piece of specialized equipment with associated costs and requirements.

The Upfront Investment

Honey extractors are a significant financial investment compared to the simple buckets and strainers used in the crush and strain method. This cost can be a barrier for those just starting in the hobby.

Operational Complexity

Using an extractor requires more steps than the crush and strain method. Frames must be uncapped (the wax sealing the cells removed), loaded carefully, spun, and then the equipment must be thoroughly cleaned and stored.

Manual vs. Automatic Extractors

For smaller operations, a simple hand-crank extractor is often sufficient. As the number of hives grows, beekeepers often upgrade to automatic extractors powered by an electric motor, which spin the frames quickly and with minimal manual effort, further increasing efficiency.

Making the Right Choice for Your Apiary

The decision to invest in an extractor should be based on your specific goals as a beekeeper.

- If your primary focus is starting with minimal investment: The crush and strain method is the most practical and low-cost way to harvest your first honey.

- If your primary focus is maximizing honey yield and colony health: An extractor is essential for preserving comb and allowing your bees to be as productive as possible.

- If your primary focus is scaling your operation beyond a few hives: An extractor is a non-negotiable tool for efficient and sustainable honey production.

Ultimately, choosing your extraction method is a strategic decision about how you invest in the long-term productivity of your apiary.

Summary Table:

| Aspect | Honey Extractor | Crush & Strain Method |

|---|---|---|

| Comb Preservation | Preserves intact comb for bees to reuse | Destroys the comb entirely |

| Bee Efficiency | Saves bees weeks of energy rebuilding | Forces bees to start from scratch |

| Beekeeper Labor | More efficient for multiple hives | Labor-intensive, practical for 1-2 hives |

| Scalability | Essential for medium/large-scale operations | Impractical for scaling an apiary |

| Initial Investment | Higher upfront cost for equipment | Very low cost, minimal equipment |

Ready to Scale Your Apiary's Efficiency?

As a commercial beekeeper or equipment distributor, maximizing honey yield and colony health is your priority. HONESTBEE supplies durable, high-performance honey extractors and beekeeping equipment designed for wholesale operations.

We help you:

- Increase Honey Production: Our extractors preserve comb, allowing your bees to produce more honey, faster.

- Reduce Labor Costs: Efficient equipment saves you valuable time during harvest.

- Scale Your Business: Reliable tools are essential for growing your apiary sustainably.

Contact HONESTBEE today to discuss the right extraction solution for your commercial needs.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

People Also Ask

- What are the benefits of using a honey extractor? Maximize Harvest & Save Bee Energy

- How long should you spin honey for? Master the Art of Efficient, Safe Extraction

- What should be considered when harvesting honey from multiple hives? Scale Your Harvest Efficiently

- What is the purpose of honey extractors? Maximize Harvest Efficiency & Preserve Honeycomb

- What machines are needed in beekeeping besides basic tools? Scale Your Honey Harvest Efficiently