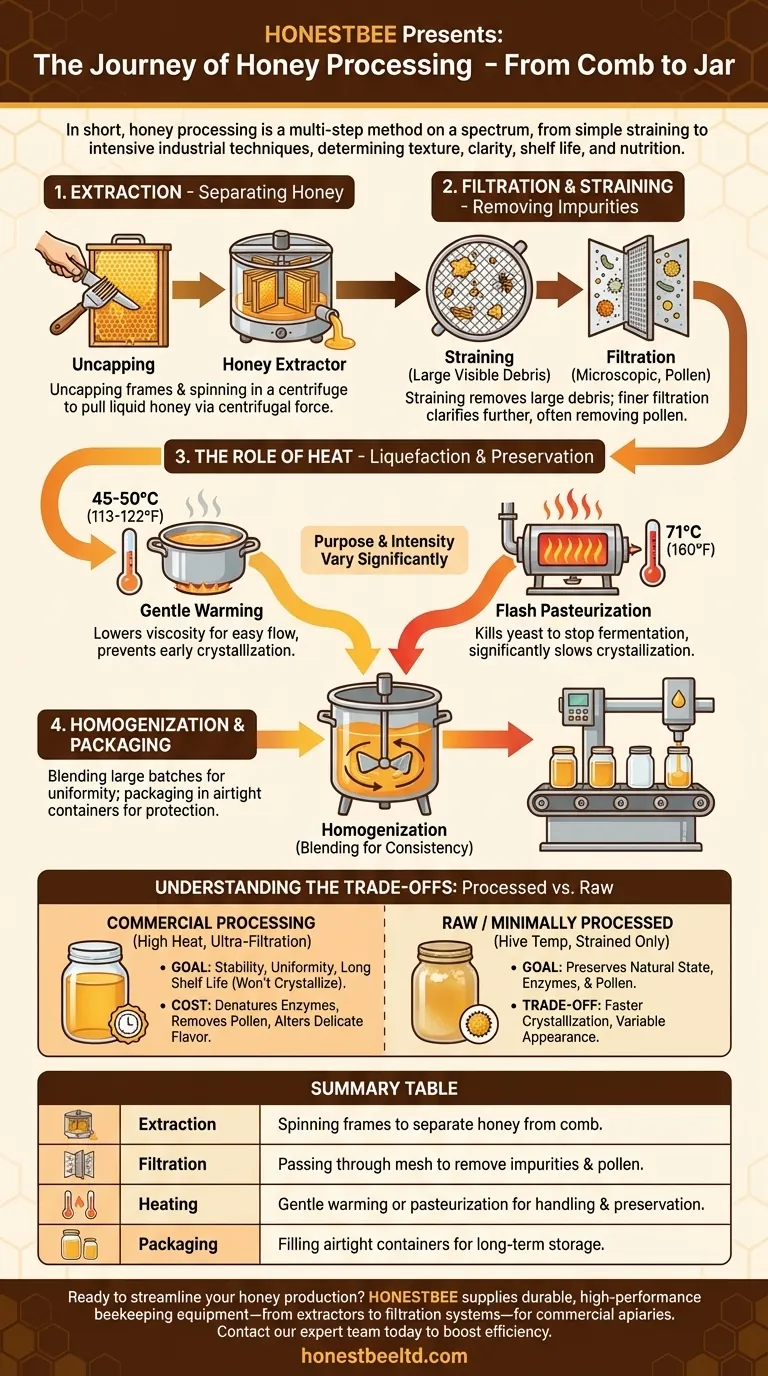

In short, honey is processed through a multi-step method that begins with extraction from the comb, followed by filtration to remove impurities, and often includes controlled heating. The specific techniques used determine the final product's texture, clarity, shelf life, and nutritional profile.

The core principle to understand is that honey processing exists on a spectrum. Methods range from simple straining that preserves the honey's natural state to intensive industrial processes involving high heat and fine filtration, designed to create a stable, consistent product for a mass market.

The Core Honey Processing Workflow

For honey to move from the beehive to a jar on a shelf, it typically undergoes a standardized series of steps. Each stage is designed to ensure the honey is clean, safe, and has a desirable consistency for consumption.

Step 1: Extraction - Separating Honey from the Comb

The process begins with removing the honey-filled frames from the hive. Beekeepers first use a special knife or fork to uncap the honeycomb, slicing off the thin wax layer that seals the honey inside each cell.

These uncapped frames are then placed in a honey extractor. This device is a centrifuge that spins the frames at high speed, using centrifugal force to pull the liquid honey out of the comb without destroying it.

Step 2: Filtration & Straining - Removing Impurities

Once extracted, the raw honey contains various particles, including bits of beeswax, bee parts, and other debris from the hive. The first cleaning step is often straining.

Straining typically involves passing the honey through a mesh screen or cloth to remove these larger visible impurities.

For a clearer product, the honey then undergoes filtration. This is a more intensive process that can involve high-pressure pumps and fine filters to remove even microscopic particles, including pollen.

Step 3: The Role of Heat - Liquefaction and Preservation

Heat is often applied during processing, but its purpose and intensity vary significantly.

Gentle warming (around 45-50°C or 113-122°F) is commonly used to lower the honey's viscosity. This makes it flow more easily, speeding up the straining and filtration process and preventing early crystallization.

Flash pasteurization, a high-heat process (around 71°C or 160°F), is used in large-scale commercial operations. This intense heat kills any wild yeast cells that could cause fermentation and significantly slows down the natural process of crystallization.

Step 4: Homogenization & Packaging

To ensure every jar from a large batch has the same color, texture, and flavor, honey may be homogenized by blending large vats together.

Finally, the finished honey is packaged into clean, airtight containers, ready for storage and distribution. This protects it from moisture and contaminants.

Understanding the Trade-offs: Processed vs. Raw

The intensity of processing directly impacts the honey's final characteristics. Understanding this trade-off is key to choosing the right product for your needs.

The Goal of Commercial Processing: Shelf Life & Consistency

The primary goals of high-heat pasteurization and ultra-filtration are stability and uniformity. This process creates the clear, liquid honey commonly seen in supermarkets. It has an exceptionally long shelf life and will not crystallize on the shelf, which is a desirable trait for many consumers and retailers.

The Cost: Altered Nutritional Value and Flavor

This stability comes at a cost. High heat denatures beneficial enzymes and can alter the delicate flavor and aroma compounds that make different honey varietals unique.

Furthermore, fine filtration removes pollen. While some consumers may prefer this for clarity, pollen is a source of protein and is what allows for the geographic and floral identification of a honey's origin.

The Alternative: "Raw" or Minimally Processed Honey

"Raw" honey is typically defined as honey that has not been heated above hive temperature (around 45°C or 113°F). It is usually only strained to remove large debris, leaving natural pollen and enzymes intact.

This method preserves the honey's natural state, character, and full nutritional profile. The trade-off is that it will crystallize much faster and may have a less consistent appearance.

Making the Right Choice for Your Goal

Your decision should be guided by what you value most in honey.

- If your primary focus is maximum shelf life and consistent clarity: Look for commercially processed honey that is perfectly clear and liquid, as this indicates it has been pasteurized and finely filtered.

- If your primary focus is preserving natural enzymes, pollen, and flavor complexity: Choose honey labeled "raw" or "unfiltered," which has been minimally strained to preserve its natural state.

- If you are dealing with crystallized honey at home: You can use the "water bath method" by gently warming the jar in a pot of warm (not boiling) water to re-liquefy it without causing significant damage.

Understanding the journey from comb to jar empowers you to select the honey that best aligns with your priorities for flavor, nutrition, and use.

Summary Table:

| Processing Step | Key Action | Purpose |

|---|---|---|

| Extraction | Spinning frames in a centrifuge | Separate honey from the comb |

| Filtration | Passing through mesh or fine filters | Remove wax, bee parts, and pollen |

| Heating | Gentle warming or flash pasteurization | Ease handling, kill yeast, delay crystallization |

| Packaging | Filling into airtight containers | Ensure hygiene and long-term storage |

Ready to streamline your honey production? HONESTBEE supplies durable, high-performance beekeeping supplies and equipment—from honey extractors to filtration systems—to commercial apiaries and distributors. Our wholesale-focused operations ensure you get the reliable tools you need for efficient, high-quality processing. Contact our expert team today to discuss your equipment needs and boost your operation's efficiency.

Visual Guide

Related Products

- 10L Stainless Steel Electric Honey Press Machine

- Stainless Steel Honey Press Wax Press with Tank

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Electric Flatting and Embossing Machine with Tray for Beekeeping

People Also Ask

- What are the advantages of using high-purity peptone solution for honey samples? Ensure Reliable Microbial Accuracy

- How does high-precision processing equipment contribute to the development of bee products? Elevate Your Brand Value

- How do honey storage tanks prevent stratification and fermentation? Expert Solutions for Large-Scale Preservation

- How does the introduction of automated honey processing equipment improve apiary profitability? Scale Your Honey Business

- What is the function of a vacuum evaporator in bee pollen extracts? Preserving Bioactive Compounds for Maximum Potency

- What are the negative impacts of lacking advanced honey Processing and Storing Equipment on your beekeeping value chain?

- What is the primary purpose of industrial-grade ethanol extraction equipment in bee pollen processing? Unlock Potency

- How do industrial constant temperature incubators facilitate the detection of pathogenic bacteria in honey? Ensure Safety