The primary methods for reducing moisture in honey involve increasing the honey's surface area and using controlled air circulation. Techniques range from using a dehumidifier in a sealed room to specialized equipment like vacuum evaporators or systems with rotating discs, which create thin films of honey to accelerate water removal.

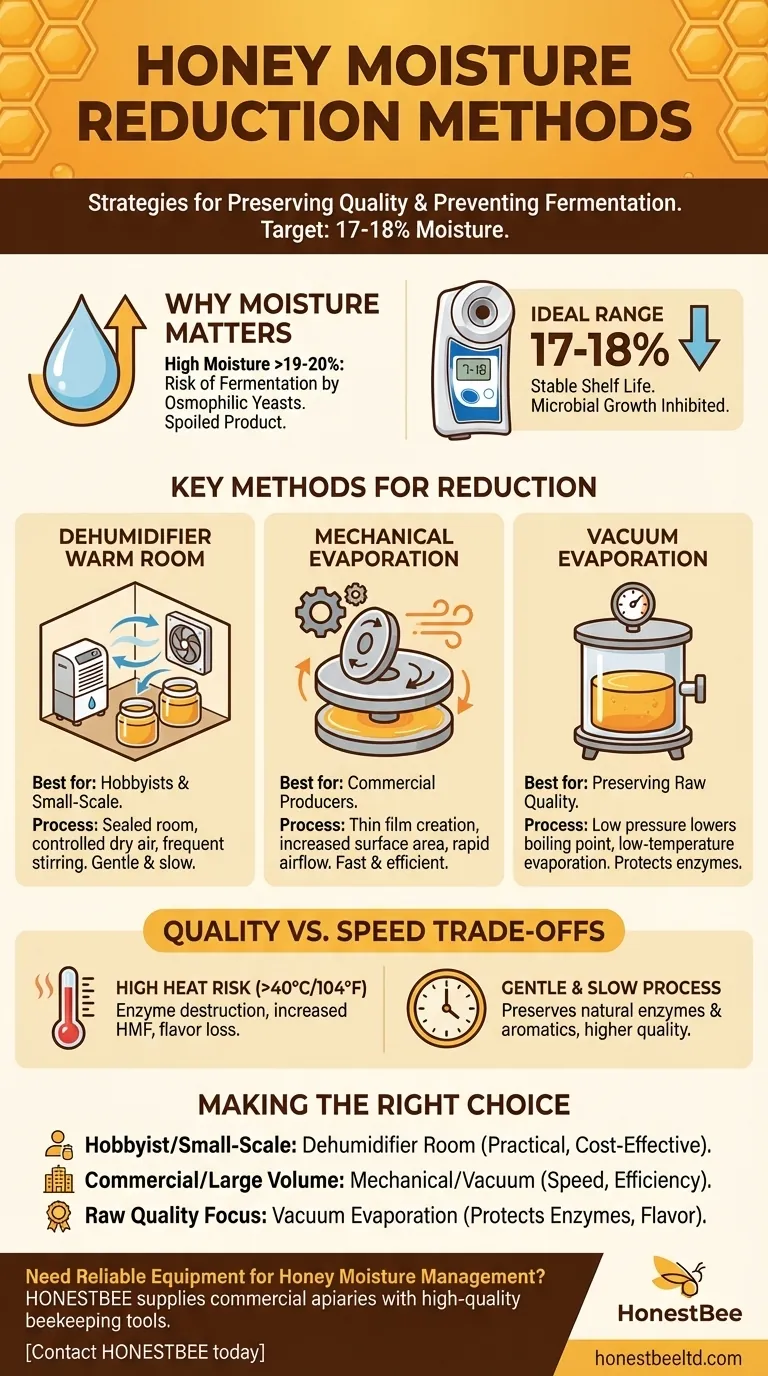

High moisture content is the single greatest threat to the shelf life of harvested honey, leading to fermentation and spoilage. The goal of any reduction method is to gently remove excess water to a target of 17-18% without damaging the honey's delicate enzymes and aromatic compounds through excessive heat.

Why Moisture Content is Critical

Honey is hygroscopic, meaning it can absorb moisture from the air. If honey is harvested before the bees have fully "ripped" it by fanning their wings, its water content will be too high.

The Threat of Fermentation

Honey with a moisture content above 19-20% is susceptible to fermentation. This process is caused by naturally occurring osmophilic yeasts that become active in higher water concentrations.

Fermented honey develops a sour, "off" flavor and can produce foam or bubbles, rendering it spoiled and unpalatable. This is the same basic process used to make mead, but it is an undesirable outcome for table honey.

The Ideal Moisture Level

The ideal moisture content for long-term preservation is between 17% and 18%. This low water activity creates an environment where yeasts and other microbes cannot survive, ensuring the honey remains stable indefinitely.

A simple tool called a refractometer is essential for accurately measuring the moisture percentage in your honey before and during the reduction process.

Key Methods for Moisture Reduction

The most effective methods focus on maximizing the honey's exposure to dry air while carefully controlling temperature.

The Dehumidifier "Warm Room" Method

This is the most accessible technique for small-scale beekeepers. It involves creating a controlled environment where a dehumidifier can slowly draw moisture out of the honey.

The process involves placing open containers of honey in a small, sealed room with a running dehumidifier and a small fan for air circulation. The honey must be stirred several times a day to expose new surfaces to the dry air.

Mechanical Evaporation Systems

Commercial operations often use specialized equipment to increase efficiency. These systems work by creating a very thin film of honey to maximize its surface area.

Methods include letting honey flow over rotating discs, cones, or wire mesh. As the honey spreads out, warm, dry air is blown over it, rapidly carrying away moisture.

Vacuum Evaporation

This is a highly effective, low-temperature method. By placing the honey in a vacuum chamber, the boiling point of water is significantly lowered.

This allows water to be evaporated out of the honey at very low temperatures, which is ideal for preserving the delicate enzymes (like diastase) and volatile flavor compounds that define high-quality, raw honey.

Understanding the Trade-offs: Quality vs. Speed

While reducing moisture is necessary, how you do it has a significant impact on the final quality of the honey.

The Danger of Direct Heat

Applying direct heat, such as with bucket heaters or microwaves, is a fast but risky method. Excessive heat degrades honey's quality.

Temperatures above 40°C (104°F) can begin to destroy beneficial enzymes and increase levels of Hydroxymethylfurfural (HMF), a chemical marker indicating heat damage or age.

The Need for Gentle Agitation

Stirring is crucial for bringing honey with higher moisture content from the bottom of the container to the surface.

However, aggressive stirring can incorporate air bubbles into the honey, which can accelerate crystallization and affect its appearance and texture. Gentle, slow movement is key.

Time is Your Ally

Slower methods, like using a dehumidifier over several days, are far gentler on the honey than rapid, high-heat techniques. The trade-off is between processing time and the preservation of the honey's natural characteristics.

Making the Right Choice for Your Goal

Your chosen method should align with your scale of production and your quality objectives.

- If you are a hobbyist or small-scale beekeeper: The dehumidifier and warm room method is the most practical and cost-effective approach for preserving honey quality without a large investment.

- If you are a commercial producer needing efficiency: A dedicated mechanical or vacuum evaporator provides the speed and precise control required for processing large volumes consistently.

- If your primary focus is preserving raw honey's value: Prioritize low-temperature methods like vacuum evaporation or a carefully managed dehumidifier to protect the honey's natural enzymes and flavor profile.

Ultimately, properly managing moisture content is the final step in honoring the bees' work and ensuring your honey remains a stable, high-quality product.

Summary Table:

| Method | Best For | Key Consideration |

|---|---|---|

| Dehumidifier Warm Room | Hobbyists & Small-Scale Beekeepers | Gentle, slow process; requires stirring |

| Mechanical Evaporation (Rotating Discs) | Commercial Producers | Fast, efficient for large volumes |

| Vacuum Evaporation | Preserving Raw Honey Quality | Best for protecting enzymes at low temperatures |

Need reliable equipment for honey moisture management? HONESTBEE supplies commercial apiaries and distributors with high-quality beekeeping supplies and equipment. Our wholesale-focused operations ensure you get the durable, efficient tools you need to maintain honey quality at scale. Contact HONESTBEE today to discuss your needs and ensure your honey remains stable and market-ready.

Visual Guide

Related Products

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- 10L Stainless Steel Electric Honey Press Machine

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

People Also Ask

- How to reduce moisture level in honey? Preserve Quality and Prevent Fermentation

- What removes moisture from the air? The Two Most Effective Methods for a Dry, Healthy Space

- What is the purpose of a honey dryer? Maximize Your Honey Yield and Quality

- What is the significance of axial fans in honey drying? Ensure Batch Consistency with Laminar Flow

- Why are UV germicidal lamps integrated into honey drying systems? Ensure Microbial Safety and Food Quality

- How much honey can a honey dryer process and by what percentage does it reduce moisture? Optimize Your Honey Production

- Why is a specialized honey dehydrating machine necessary for processing stingless bee honey? Prevent Spoilage Fast

- How to decrease moisture in honey? Prevent Fermentation and Ensure Long-Term Quality