Before using a honey extractor, the essential preparation involves two main phases: gathering the correct equipment and uncapping the honey frames. Uncapping is the critical step of removing the protective wax cappings that bees place over filled honey cells, which is typically done with a heated knife or an uncapping fork.

The success of honey extraction hinges not on the spinning itself, but on the systematic preparation that precedes it. A well-organized workspace and properly uncapped frames are the foundation for an efficient, clean, and successful harvest.

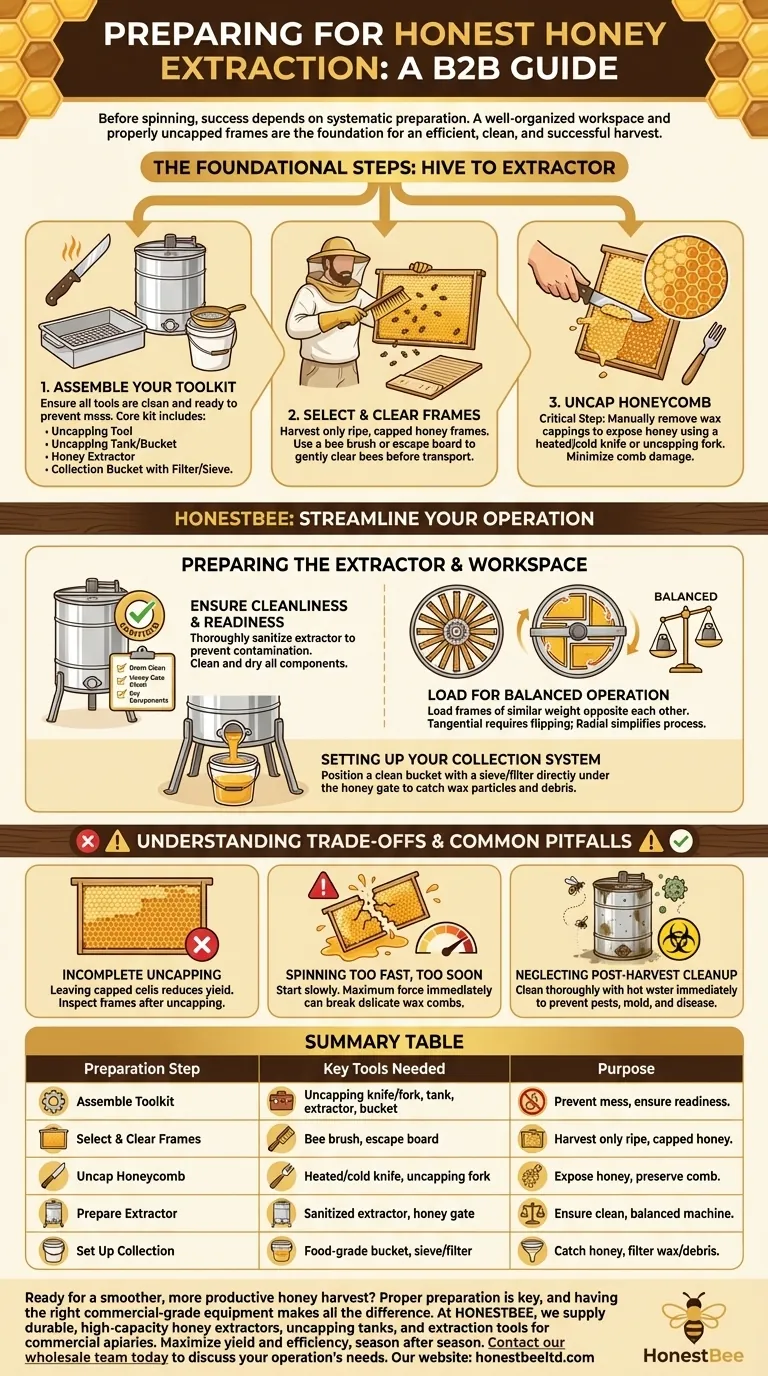

The Foundational Steps: From Hive to Extractor

Properly preparing your frames and equipment is the most important part of the extraction process. Rushing these steps often leads to frustration and a lower honey yield.

Assembling Your Extraction Toolkit

Before you bring a single frame indoors, ensure all your tools are clean and ready. This prevents a sticky, chaotic mess.

Your core kit should include an uncapping tool (like a heated knife, fork, or roller), a container to catch the wax cappings (an uncapping tank or a simple bucket), the honey extractor itself, and a collection bucket with a filter or sieve placed under the extractor's honey gate.

Selecting and Removing the Right Frames

Your goal is to harvest frames that are filled with ripe, capped honey. The wax cappings indicate the honey has the correct moisture content and is ready for long-term storage.

Use a bee brush or an escape board to gently clear the bees from the frames you intend to harvest before bringing them to your extraction space.

The Critical Step: Uncapping the Honeycomb

The extractor uses centrifugal force to pull honey from the cells, but it cannot penetrate the wax seal. You must manually remove these cappings.

Using a long, fluid motion, slice off the cappings with a heated or cold uncapping knife. For any missed areas, an uncapping fork or scratcher works perfectly to pierce the remaining seals. The goal is to expose the honey with minimal damage to the underlying wax comb structure.

Preparing the Extractor and Workspace

Once your frames are uncapped, the focus shifts to the extractor itself and the immediate environment.

Ensuring Your Extractor is Clean and Ready

Begin with a thoroughly sanitized extractor. Any residue from a previous harvest can contaminate your honey and potentially spread bee diseases. Ensure all components, especially the drum and the honey gate, are clean and dry.

Loading Frames for Balanced Operation

An unbalanced extractor will vibrate violently and can even damage the equipment. You must load the frames to create a balanced weight distribution.

Place frames of similar weight directly opposite each other. In a tangential extractor, the frames will need to be flipped halfway through. In a radial extractor, honey is slung from both sides simultaneously, simplifying the process.

Setting Up Your Collection System

Position a clean, food-grade bucket directly under the honey gate or spigot. To save a step later, place a sieve or filter (like cheesecloth or a purpose-built honey filter) over the bucket to catch wax particles and debris as the honey flows out.

Understanding the Trade-offs and Common Pitfalls

Knowing the common mistakes can save you significant time and effort.

Incomplete Uncapping

If you leave capped cells on the frame, the honey inside them will not be extracted. A quick inspection after uncapping is crucial to ensure you get the maximum yield from each frame.

Spinning Too Fast, Too Soon

Applying maximum force immediately can cause the delicate wax combs to "blow out" and break apart, especially on frames that are only supported on one side in a tangential extractor. Always start slowly and gradually increase the speed.

Neglecting Post-Harvest Cleanup

Honey is sticky and attracts pests. More importantly, it can harbor disease spores. Thoroughly cleaning your extractor and all tools with hot water immediately after you finish prevents fermentation, mold, and the potential spread of disease back to your hives.

How to Apply This to Your Harvest

Your preparation can be tailored to match your goals and the scale of your operation.

- If your primary focus is a small, hobbyist harvest: A cold uncapping knife and a simple bucket to catch cappings is perfectly sufficient.

- If your primary focus is speed and efficiency: Investing in an electric heated knife, a dedicated uncapping tank, and a radial extractor will dramatically accelerate the process.

- If your primary focus is preserving pristine comb: Always start the extractor at a low speed and gradually ramp up, especially when using a tangential model, to minimize stress on the wax.

By focusing on this deliberate preparation, you transform honey extraction from a frantic, sticky task into a rewarding and efficient culmination of your beekeeping season.

Summary Table:

| Preparation Step | Key Tools Needed | Purpose |

|---|---|---|

| Assemble Toolkit | Uncapping knife/fork, uncapping tank, extractor, collection bucket | Prevent mess and ensure all equipment is ready. |

| Select & Clear Frames | Bee brush, escape board | Harvest only ripe, capped honey frames. |

| Uncap Honeycomb | Heated/cold knife, uncapping fork | Expose honey cells for extraction while preserving comb. |

| Prepare Extractor | Sanitized extractor, honey gate | Ensure a clean, balanced, and ready-to-use machine. |

| Set Up Collection | Food-grade bucket, sieve/filter | Catch honey while filtering out wax and debris. |

Ready for a smoother, more productive honey harvest?

Proper preparation is key, and having the right commercial-grade equipment makes all the difference. At HONESTBEE, we supply durable, high-capacity honey extractors, uncapping tanks, and the full suite of extraction tools trusted by commercial apiaries and beekeeping equipment distributors.

We help you maximize yield and efficiency, season after season.

Contact our wholesale team today to discuss your operation's needs and explore our catalog.

Visual Guide

Related Products

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- 6 Frame Manual Stainless Steel Honey Extractor Beekeeping Equipment

- 2 Frame Stainless Steel Manual Honey Spinner Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- How does the centrifugal extraction process contribute to melissopalynology? Unlock Precise Honey Pollen Analysis

- How do specialized honey extracting machines contribute to operational efficiency? Scale Your Apiary Production

- Can a manual extractor be upgraded to an electric one? Save Labor & Boost Efficiency

- Why is a benchtop centrifuge necessary for honey extraction analysis? Ensure Purity for Reliable Quality Testing

- What is the primary benefit of using a honey extractor compared to older methods? Boost Yield & Save Your Bees' Energy

- What are the benefits of using an industrial-grade electric drive system for honey extractors? Boost Efficiency Today

- What is a centrifuge honey extractor and why is it significant? Maximize Hive Health & Honey Yields

- What is the "Crush-and-Strain" method for honey extraction? A Simple Low-Cost Guide for Beekeepers