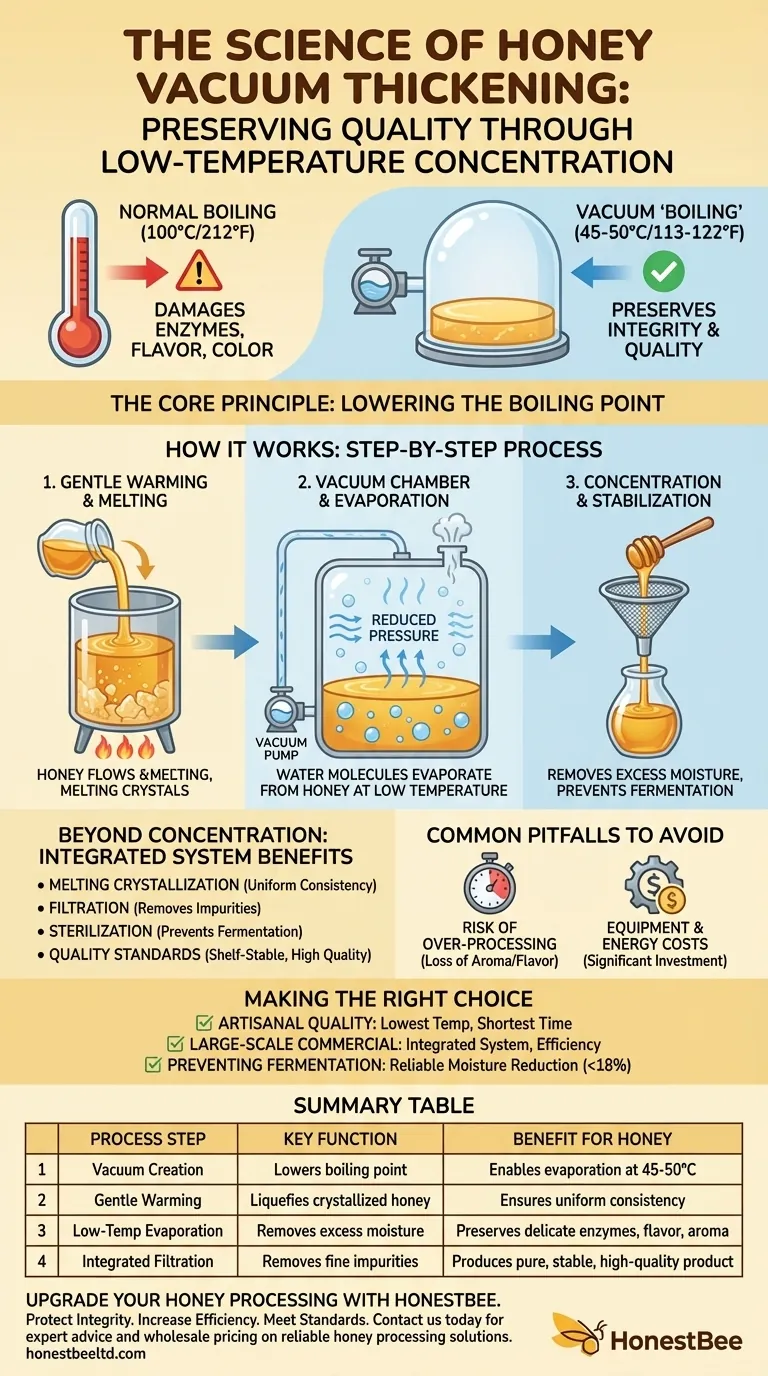

At its core, a honey vacuum thickener works by exploiting a fundamental principle of physics. It creates a high-vacuum environment, which dramatically lowers the boiling point of water. This allows the excess water in the honey to evaporate quickly at a low temperature, increasing the honey's concentration without damaging its delicate qualities.

The central challenge in processing honey is removing water without using high heat, which would destroy its enzymes, flavor, and color. A vacuum thickener solves this by making water "boil" at a temperature low enough to protect the honey's integrity.

The Core Principle: Overcoming the Heat Problem

To understand why vacuum technology is essential, we must first recognize the problem it solves: the destructive nature of high heat on honey.

Why Normal Boiling is Unacceptable

Honey is a sensitive biological product. Heating it to the normal boiling point of water (100°C or 212°F) would cause significant damage.

This level of heat would destroy beneficial enzymes like diastase and invertase, which are key indicators of honey quality.

Furthermore, it would caramelize the sugars, permanently altering the honey's color, creating off-flavors, and destroying its subtle floral aromas.

The Role of the Vacuum

A vacuum pump removes air from the processing tank, drastically reducing the atmospheric pressure inside.

Think of normal air pressure as a heavy lid pressing down on the water in the honey, making it difficult for water molecules to escape as steam.

By removing that pressure, the "lid" is lifted. Water molecules can escape much more easily, allowing evaporation—or "boiling"—to occur at a much lower, safer temperature, often around 45-50°C (113-122°F).

How the Process Works in Practice

The honey is gently warmed, often just enough to melt any existing sugar crystals.

A vacuum is then applied to the chamber, and the low-temperature evaporation process begins.

This removes the excess moisture content efficiently, raising the honey's sugar concentration and making it shelf-stable without compromising its essential character.

Beyond Concentration: An Integrated System

Modern honey thickeners are often multi-functional systems designed to perform several quality-control steps in a single, efficient process.

Melting Crystallization

The initial gentle warming stage serves to liquefy any crystallized honey, ensuring a smooth and uniform consistency before the concentration phase begins.

Filtration and Sterilization

Many systems incorporate filtration to remove fine impurities like wax particles or pollen. The low-temperature process also helps to sterilize the honey by removing the excess water that microbes and yeast need to thrive, preventing fermentation.

The Goal: Meeting Quality Standards

The ultimate objective is to produce honey that is stable, pure, and meets national or international standards for moisture content. This ensures the final product has a long shelf life and retains the high quality consumers expect.

Common Pitfalls to Avoid

While effective, vacuum concentration is a precise process that requires careful management to avoid potential downsides.

Risk of Over-Processing

Even at low temperatures, leaving the honey under vacuum for too long can be detrimental. This can strip away some of the more volatile aromatic compounds that contribute to the honey's unique flavor and scent profile.

Equipment and Energy Costs

Vacuum processing equipment is a significant capital investment compared to simple heating tanks. The machinery is complex and requires specialized knowledge to operate and maintain correctly. It also consumes considerable energy to run the vacuum pumps and heating/cooling systems.

Making the Right Choice for Your Goal

Applying this technology depends entirely on the desired outcome, balancing the preservation of quality with the demands of production.

- If your primary focus is preserving artisanal quality: The key is to use the lowest possible temperature and shortest processing time necessary to achieve the target moisture level.

- If your primary focus is large-scale commercial production: An integrated vacuum system offers unmatched efficiency for creating a consistent, standardized, and shelf-stable product.

- If your primary focus is preventing fermentation: Vacuum concentration is the most reliable method for reducing water content below the 18% threshold required to ensure long-term stability.

Ultimately, vacuum concentration is the industry standard for protecting the natural essence of honey while preparing it for the market.

Summary Table:

| Process Step | Key Function | Benefit for Honey |

|---|---|---|

| Vacuum Creation | Lowers boiling point of water | Enables evaporation at 45-50°C (113-122°F) |

| Gentle Warming | Liquefies crystallized honey | Ensures uniform consistency for processing |

| Low-Temp Evaporation | Removes excess moisture | Preserves delicate enzymes, flavor, and aroma |

| Integrated Filtration | Removes fine impurities | Produces a pure, stable, and high-quality final product |

Upgrade Your Honey Processing with HONESTBEE

As a trusted supplier of beekeeping supplies and equipment for commercial apiaries and distributors, HONESTBEE understands the critical balance between quality and efficiency. Our honey vacuum thickeners are designed to help you:

- Protect Product Integrity: Safely concentrate honey without damaging its natural enzymes, color, and delicate flavors.

- Increase Production Efficiency: Achieve consistent, shelf-stable results on a commercial scale.

- Meet Quality Standards: Ensure your honey meets rigorous moisture content requirements to prevent fermentation.

Let us help you invest in the right equipment for your goals. Contact HONESTBEE today for expert advice and wholesale pricing on reliable honey processing solutions.

Visual Guide

Related Products

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

- Professional 4 Frame Self Reversing Electric Honey Extractor for Beekeeping

- HONESTBEE 6 Frame Self Reversing Electric Honey Extractor for Beekeeping

People Also Ask

- Why is industrial-grade dehumidification equipment essential for producing commercial-standard honey? Expert Insights

- What are the generally recommended drying conditions for honey? Maintain Quality with Optimal Heat and Moisture

- Why is the use of dry sieves and storage containers critical? Prevent Honey Fermentation and Spoilage

- How do high-efficiency honey dehydration and filtration systems enhance honey quality and unit yield? Optimize Your Honey

- How does the internal ventilation management of a beehive affect the efficiency of honey dehydration?