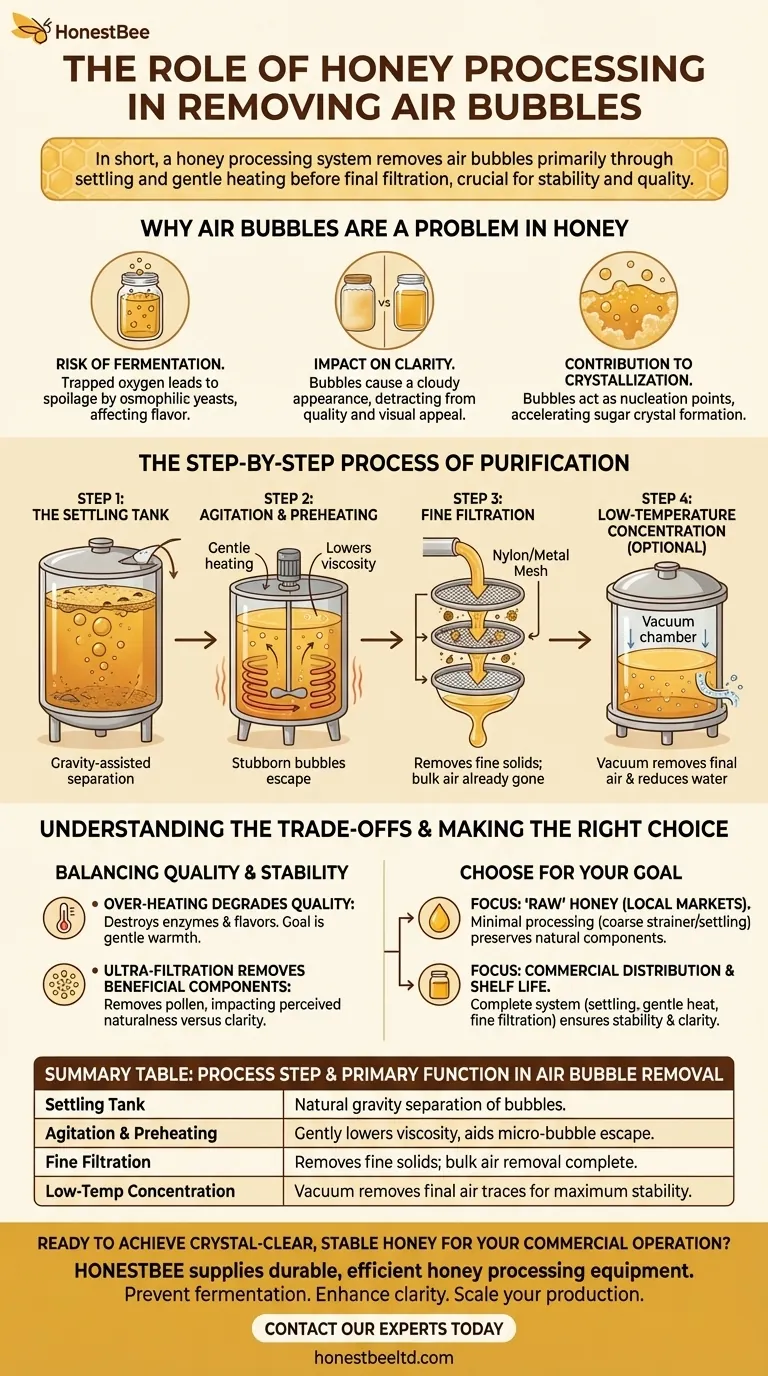

In short, a honey processing system removes air bubbles primarily through settling and gentle heating. These steps occur before the final filtration stage and are crucial for preventing fermentation and ensuring the honey's long-term stability and visual appeal.

The core challenge in honey processing is not just filtering out solid particles, but stabilizing the honey to create a pure, clear, and shelf-stable product. Removing trapped air is a critical part of this stabilization process, directly impacting quality and preventing spoilage.

Why Air Bubbles are a Problem in Honey

Air gets trapped in honey during extraction, pumping, and handling. While seemingly minor, these bubbles can significantly degrade the final product if not properly removed.

The Risk of Fermentation

Trapped air, especially oxygen, can create an environment where naturally occurring osmophilic yeasts can thrive. This leads to fermentation, spoiling the honey's flavor and rendering it unsellable.

Impact on Clarity and Appearance

Air bubbles create a cloudy or foamy appearance in the jar. For commercial producers, a crystal-clear product is often a key indicator of quality for consumers, and bubbles detract from this visual standard.

Contribution to Crystallization

Air bubbles can act as nucleation points, which are tiny sites where sugar crystals begin to form. By removing them, you can slow the natural process of crystallization and extend the honey's liquid state on the shelf.

The Step-by-Step Process of Purification

A "honey filtering machine" is more accurately described as a complete honey processing line. The removal of air bubbles happens as part of a multi-stage workflow designed to purify and stabilize the honey.

Step 1: The Settling Tank

After extraction from the honeycomb, honey is typically held in a settling tank. Here, gravity does the initial work.

Lighter impurities, such as wax particles, debris, and most importantly, air bubbles, naturally rise to the surface over time. This layer is then skimmed off, completing the first and most significant step in de-aeration.

Step 2: Agitation and Preheating

To improve flow and facilitate finer filtering, honey is often gently heated. This mild heat lowers the honey's viscosity (makes it thinner).

This reduced viscosity allows even the smallest, most stubborn air bubbles to escape and rise to the surface much more easily before the honey moves to the next stage.

Step 3: Fine Filtration

This is the step most people associate with filtering. The warmed honey is passed through a series of fine nylon or metal mesh filters.

The primary purpose here is to remove small suspended solids like pollen grains and tiny wax particles that did not rise during settling. While this stage ensures purity, the bulk of the air has already been removed.

Step 4: Low-Temperature Concentration

In some industrial systems, a final step may involve using a vacuum to concentrate the honey. This process further reduces water content and removes any final residual air, resulting in an exceptionally pure and stable product.

Understanding the Trade-offs

Achieving perfect clarity and stability requires careful balance. Aggressive processing can compromise the honey's natural qualities.

Over-Heating Degrades Quality

Heating honey too much or too quickly can destroy its delicate enzymes, aromas, and flavors. The goal is to apply just enough warmth to improve fluidity for filtering without "cooking" the honey.

Ultra-Filtration Removes Beneficial Components

Using extremely fine filters can remove beneficial components like pollen. While this creates a very clear product that crystallizes slowly, it also removes what many consumers consider a key part of natural, raw honey. This is a critical trade-off between shelf stability and perceived naturalness.

Mechanical Handling Can Re-introduce Air

Every time honey is pumped or transferred, there is a risk of re-introducing air. Using specialized, low-shear honey pumps and minimizing agitation during bottling are essential to preserving the quality achieved during processing.

Making the Right Choice for Your Goal

The level of processing required depends entirely on your final objective.

- If your primary focus is producing "raw" honey for local markets: Minimal processing using only a coarse strainer or settling tank may be sufficient to preserve all natural components.

- If your primary focus is commercial distribution and long shelf life: A complete system with gentle heating, settling, and fine filtration is necessary to ensure a stable, clear, and consistent product that meets consumer expectations.

Ultimately, managing air bubbles is a key control point in transforming raw honey from the hive into a high-quality finished product.

Summary Table:

| Process Step | Primary Function in Air Bubble Removal |

|---|---|

| Settling Tank | Allows air bubbles to naturally rise to the surface via gravity for skimming. |

| Agitation & Preheating | Gently lowers honey's viscosity, helping stubborn micro-bubbles escape. |

| Fine Filtration | Removes fine solids; bulk of air removal is already complete from previous steps. |

| Low-Temp Concentration (Optional) | Uses a vacuum to remove final traces of air and water for maximum stability. |

Ready to achieve crystal-clear, stable honey for your commercial operation?

HONESTBEE supplies the durable, efficient honey processing equipment that commercial apiaries and distributors rely on. Our wholesale-focused solutions are designed to help you:

- Prevent fermentation by effectively removing air bubbles.

- Enhance product clarity and shelf appeal for your customers.

- Scale your production with reliable, professional-grade machinery.

Contact our experts today to find the perfect honey filtering and purification system for your business goals!

Visual Guide

Related Products

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- Honeycomb Style Drip Free Honey Dispenser

- 10L Stainless Steel Electric Honey Press Machine

- Premium Diamond-Faceted Glass Honey Dispenser

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- Can raw honey be filtered? Unlock the Truth About Processing & Purity

- What is the primary purpose of multi-stage honey filtration? Achieve Visual Clarity and Purity Without Compromise

- Why is a dual-layer stainless steel filtration system required in honey processing? Optimize Purity and Efficiency

- What is the function of the filtration process in the pretreatment of Acacia honey samples? Achieve Analytical Precision

- What are the technical objectives of using industrial honey filtration systems in large-scale honey factories?

- In what ways do advanced honey extraction and filtration systems enhance market competitiveness? Optimize Your Output

- What is the role of industrial-grade honey filtration and filling systems in mitigating lead contamination?

- How do industrial honey filtration systems increase the market value of honey products? Boost Your Honey Quality