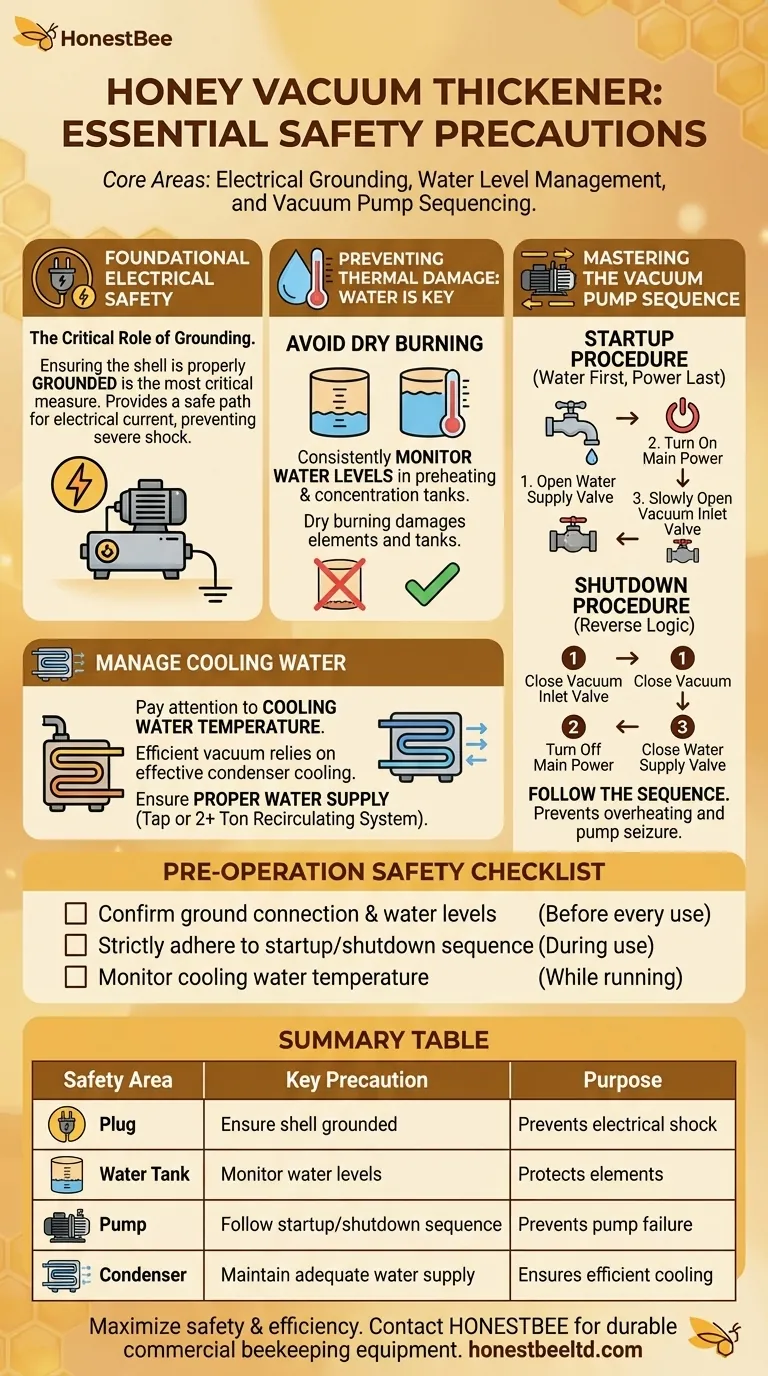

The essential safety precautions for operating a honey vacuum thickener revolve around three core areas: electrical grounding, water level management, and correct vacuum pump sequencing. Adhering to these protects the operator from electrical shock and the machine from critical damage like dry burning or pump failure.

Safe operation is not just about personal safety; it's about protecting the equipment's integrity and ensuring the quality of your honey. The entire process hinges on the correct management of electrical, thermal, and vacuum systems.

Foundational Electrical Safety

A single point of failure can create a significant hazard. The first step in any operation is to confirm the machine's electrical integrity.

The Critical Role of Grounding

Ensuring the shell of the thickener is properly grounded is the most critical electrical safety measure. This provides a safe path for electrical current to flow in the event of a fault, preventing the machine's metal body from becoming energized and causing a severe electrical shock.

Preventing Thermal Damage: Water is Key

The honey thickener uses heated water jackets for preheating and concentration. Mismanaging these water systems is the fastest way to cause expensive, irreversible damage to the equipment.

Monitor Water Levels to Avoid Dry Burning

You must consistently monitor the water levels in the preheating and concentration tanks. If the heating elements are turned on without being fully submerged in water, they will "dry burn," quickly overheating and failing. This can also damage the tank walls.

Manage Cooling Water Temperature

Pay close attention to the temperature of the cooling water during the concentration process. An efficient vacuum depends on the condenser effectively cooling water vapor back into a liquid. If the cooling water becomes too warm, vacuum efficiency drops, potentially overheating the system and the vacuum pump.

Ensure a Proper Water Supply Setup

Your water source must be adequate. If using tap water, ensure the inlet pipe is connected to the condenser's water inlet, and the outlets from the condenser and vacuum pump are routed to a drain.

If you are using a recirculating water system, you must have a water tank with a capacity of at least 2 tons and a pump with a power of approximately 0.37Kw. An undersized system cannot dissipate heat effectively.

Mastering the Vacuum Pump Sequence

The vacuum pump is a sensitive piece of machinery that requires a precise startup and shutdown procedure to prevent damage.

The Correct Startup Procedure

To start the vacuum pump, always follow this sequence:

- Open the water supply valve first.

- Turn on the main power supply.

- Slowly open the vacuum inlet valve.

The Correct Shutdown Procedure

To stop the vacuum pump, reverse the logic:

- Close the vacuum inlet valve first.

- Turn off the main power supply.

- Close the water supply valve last.

Why This Sequence Matters

Following this sequence is not optional. Running the pump without water can cause it to overheat and seize. Shutting off the water before the power can cause similar damage or create a backflow issue.

Common Operational Pitfalls to Avoid

Mistakes often happen not from a lack of knowledge, but from a lapse in process. Being aware of common failure points is key to consistent, safe operation.

Neglecting Pre-operation Checks

The most common pitfall is rushing into operation. Before every single run, physically verify the ground connection and confirm water levels in all relevant tanks.

Improper Shutdown

Failing to follow the precise shutdown sequence for the vacuum pump is a primary cause of premature pump failure. Always close the inlet valve before cutting power.

Inadequate Cooling

Using an undersized water tank for a recirculating system or having low tap water pressure can lead to inadequate cooling. This reduces machine efficiency and puts thermal stress on the entire system.

A Pre-Operation Safety Checklist

Use this simple checklist to build a safe and repeatable operational habit.

- Before every use: Confirm the equipment shell is securely grounded and check that water levels in the preheating and concentration tanks are sufficient.

- During startup and shutdown: Strictly adhere to the "water first, power last" and "power first, water last" sequences for the vacuum pump.

- While the machine is running: Actively monitor cooling water temperature and periodically re-check water levels to prevent dry burning.

By integrating these safety precautions into your standard operating procedure, you ensure the longevity of the equipment and the safety of its operator.

Summary Table:

| Safety Area | Key Precaution | Purpose |

|---|---|---|

| Electrical Safety | Ensure machine shell is properly grounded | Prevents electrical shock from faults |

| Thermal Management | Monitor water levels in tanks to avoid dry burning | Protects heating elements and tank walls |

| Vacuum Pump Operation | Follow correct startup/shutdown sequence (water first, power last) | Prevents pump overheating and failure |

| Cooling System | Maintain adequate cooling water supply and temperature | Ensures efficient vacuum and system cooling |

Maximize the safety and efficiency of your honey processing operation. For commercial apiaries and distributors, proper equipment handling is paramount to protecting your investment and ensuring consistent, high-quality honey production. HONESTBEE supplies durable, reliable beekeeping equipment and supplies designed for demanding commercial use. Our expert team can provide guidance on best practices and the right tools for your scale. Contact HONESTBEE today to discuss your wholesale equipment needs and secure your operation's success.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

People Also Ask

- What are the main components of a packaging machine? A Guide to Essential Systems for Production Efficiency

- How do specialized honey processing and storage workshops help maintain honey quality in tropical climate conditions?

- What is the primary role of high-power microwave convection equipment in the sterilization of honey? Boost Efficiency

- What are the primary technical differences between the production of raw honey and processed honey? Key Comparisons

- How is a spectrophotometer utilized to measure diastase activity in honey? Ensure Freshness & Quality Standards

- What is the role of a high-speed centrifuge in honey sample pretreatment? Optimize Pathogen Detection and DNA Yield

- What is the primary function of a laboratory conductivity meter in honey analysis? Authenticate Honey Botanical Origin

- What customization options are available for honey processing equipment? Tailor Your System for Maximum Efficiency