Proper maintenance of honey filtering equipment is a straightforward, multi-step process centered on cleaning, inspection, and drying. The essential steps involve washing all components with warm water and a mild detergent immediately after use, inspecting filters for any wear, ensuring every part is completely dry to prevent corrosion, and periodically checking for any leaks or loose fittings.

At its core, maintaining your filtering equipment is not just about extending its lifespan. It is a critical practice for safeguarding the purity, quality, and natural properties of your final honey product.

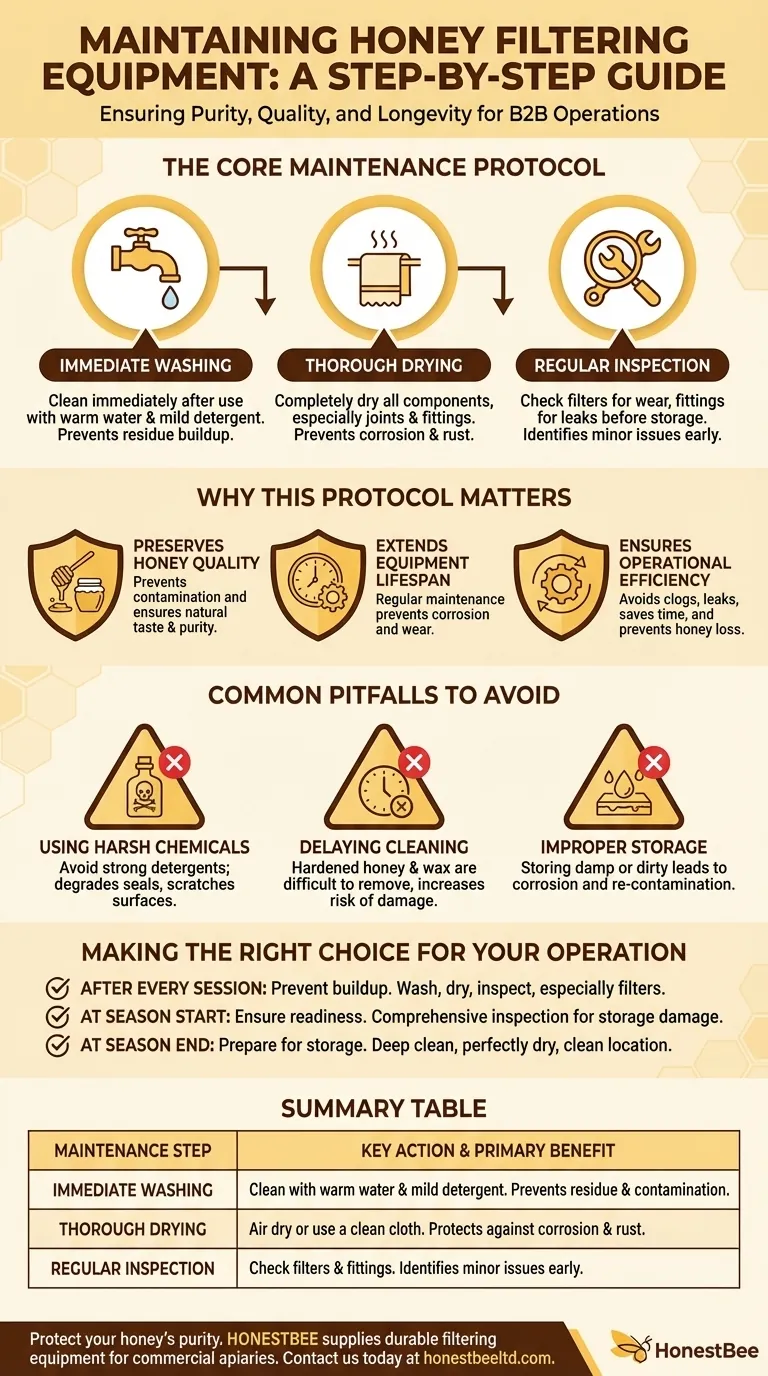

The Core Maintenance Protocol

Effective maintenance hinges on a consistent routine performed after every filtering session. This prevents the buildup of residue that can compromise both your equipment and your honey.

Step 1: Immediate Washing

The most critical step is to clean the equipment immediately after use. Honey and wax residue can harden, making them significantly harder to remove later and potentially harboring bacteria.

Use warm water and a mild, food-safe detergent to wash all components, including strainers, filters, pumps, and tanks. This dissolves residual honey and wax without damaging the equipment.

Step 2: Thorough Drying

Moisture is the primary cause of corrosion and rust, especially on metal parts. After washing, every component must be dried completely.

Using a clean cloth or air drying are both effective methods. Pay special attention to joints, seams, and fittings where water can get trapped.

Step 3: Regular Inspection

Before storing the equipment, conduct a quick inspection. This proactive check helps you identify minor issues before they become significant problems.

Look for signs of wear and tear on your filters, as a damaged filter will not remove impurities effectively. Also, check for any loose fittings or potential leaks in the system.

Why This Protocol Matters

Adhering to a strict maintenance schedule directly impacts the efficiency of your operation and the quality of your product. Neglecting these steps has tangible consequences.

To Preserve Honey Quality

Clean equipment is essential for preventing contamination. Leftover residue can introduce unwanted flavors or bacteria into your next batch, compromising the honey's natural taste and purity.

To Extend Equipment Lifespan

Honey filtering equipment is an investment. Regular cleaning and drying prevent corrosion and rust, while inspections catch wear and tear early, significantly extending the functional life of your tools.

To Ensure Operational Efficiency

Clogged filters and leaking fittings slow down the filtering process and create unnecessary mess. A well-maintained system functions smoothly, saving you time and preventing honey loss.

Common Pitfalls to Avoid

Simple mistakes in the maintenance process can inadvertently damage your equipment or compromise your honey.

Using Harsh Chemicals

Avoid strong detergents, abrasive cleaners, or harsh chemicals. These can degrade seals, scratch stainless steel surfaces, and potentially leave behind residues that will contaminate your honey.

Delaying the Cleaning Process

Procrastinating on cleaning is a common mistake. Once honey crystallizes and wax hardens inside the equipment, it requires much more time and effort to clean, increasing the risk of scratching surfaces during removal.

Improper Storage

Storing equipment while it is still damp or in a dusty environment will undo all your cleaning efforts. Dampness leads to corrosion, and an unclean environment can re-contaminate the surfaces before their next use. Always store in a clean, dry location.

Making the Right Choice for Your Operation

A consistent schedule is the key to turning maintenance from a chore into a professional habit that protects your investment and your product.

- After every filtering session: Your goal is to prevent buildup. Immediately wash, thoroughly dry, and inspect all components, especially the filters.

- At the beginning of each season: Your goal is to ensure readiness. Conduct a comprehensive inspection of all parts, checking for any corrosion, wear, or damage that may have occurred during storage.

- At the end of the season: Your goal is to prepare for storage. Perform a final, deep clean and ensure every piece is perfectly dry before storing it in a clean, protected area.

Ultimately, disciplined maintenance is the foundation for consistently producing high-quality, pure honey.

Summary Table:

| Maintenance Step | Key Action | Primary Benefit |

|---|---|---|

| Immediate Washing | Clean with warm water & mild detergent after each use. | Prevents residue buildup and bacterial contamination. |

| Thorough Drying | Air dry or use a clean cloth on all parts. | Protects against corrosion and rust. |

| Regular Inspection | Check filters for wear and fittings for leaks. | Identifies minor issues before they become major problems. |

Protect your honey's purity and your equipment's longevity. Proper maintenance is non-negotiable for commercial apiaries and distributors. HONESTBEE supplies the durable, high-performance filtering equipment and beekeeping supplies your operation needs. Our wholesale-focused operations are designed to support your business with reliable gear that stands up to rigorous use. Contact HONESTBEE today to discuss your equipment needs and ensure every batch of honey meets the highest standards.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Professional Thermostatic Conical Honey Melter

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What function does honey filtration and clarification equipment serve? Enhance Purity and Value in Your Production

- What are the benefits of using a honey filtering machine? Boost Purity, Efficiency & Market Appeal

- Why is the use of high-density filter cloth necessary during the processing of stingless bee honey? Ensure Pure Quality

- How does a vacuum filtration system with multi-stage filter papers function? Optimize Royal Jelly Purity and Clarity

- What is the role of straining and filtration in beeswax candle manufacturing? Ensure Clean Burns and Premium Quality

- What is the function of the filtration process in the pretreatment of Acacia honey samples? Achieve Analytical Precision

- Why is high-efficiency pressure filtration necessary for forest honey? Master Purity in Squeezed Honey Extraction

- Why is honey pollen filtration equipment regulated? Protect Your Trade Integrity & Traceability