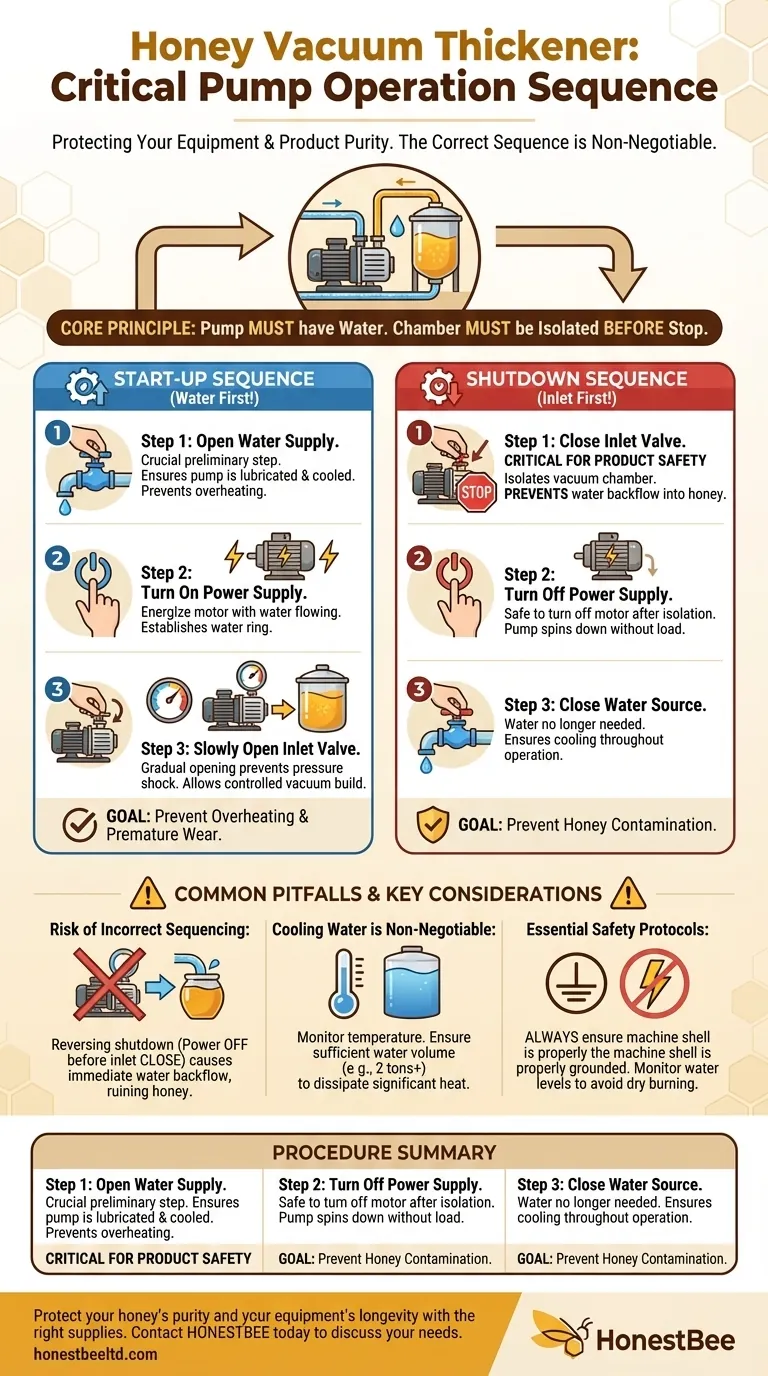

The correct operational sequence is non-negotiable. To start the vacuum pump on your honey thickener, you must first open the water supply, then turn on the power, and finally, slowly open the inlet valve. For shutdown, the reverse is critical: first close the inlet valve, then turn off the power, and lastly, close the water source.

The core principle is simple: the pump must never run without its cooling and sealing water, and the vacuum chamber must always be isolated from the pump before the pump stops. Following this sequence prevents pump damage and, most importantly, protects your honey from contamination.

The Critical Start-Up Sequence Explained

Understanding the "why" behind each step transforms a simple checklist into a reliable operational habit. Each action serves a specific purpose in protecting both the equipment and your final product.

Step 1: Open the Water Supply First

This is the most crucial preliminary step. Water-ring vacuum pumps use a ring of water to create a seal and dissipate the heat generated by compression. Starting the water flow before the motor ensures the pump is lubricated and cooled from the very first rotation, preventing overheating and premature wear.

Step 2: Turn on the Power Supply

With the water flowing, you can safely energize the pump's motor. The pump will begin to run, establishing the internal water ring necessary for creating a vacuum.

Step 3: Slowly Open the Inlet Valve

The inlet valve connects the pump to the honey concentration tank. Opening this valve slowly is key. A gradual opening prevents a sudden pressure shock to the system and your product, allowing the vacuum to build in a controlled and steady manner.

The Correct Shutdown Procedure

Shutting down the pump correctly is just as important as starting it up. The goal is to safely stop the vacuum process without introducing contaminants back into the system.

Step 1: Close the Inlet Valve First

This is the single most important step for product safety. Closing the inlet valve isolates the vacuum chamber (containing your honey) from the pump. This action prevents any of the pump's sealing water from being sucked back into the honey tank when the vacuum breaks, which would contaminate your batch.

Step 2: Turn Off the Power Supply

Once the system is isolated, you can safely turn off the pump's motor. The pump will spin down without being under any vacuum load, which is better for the equipment.

Step 3: Close the Water Source

With the pump motor off, the cooling and sealing water is no longer needed. You can now close the water supply valve. Leaving the water on until the end ensures the pump was cooled for the entire duration of its operation.

Common Pitfalls and Key Considerations

Adhering to the procedure is about mitigating risk. A few key points must be monitored during every operation to ensure safety and efficiency.

The Risk of Incorrect Sequencing

Reversing the shutdown order (turning off the power before closing the inlet valve) is a common and costly mistake. When the pump stops, the vacuum in the tank will immediately pull the water from inside the pump back into the tank, ruining the honey.

Why Cooling Water is Non-Negotiable

The process of creating a vacuum generates significant heat. You must monitor the temperature of the cooling water throughout the concentration process. If using a recirculating system, ensure your water tank is sufficiently large (e.g., 2 tons or more) to effectively dissipate this heat.

Essential Safety Protocols

Before any operation, always ensure the machine's shell is properly grounded. This is a fundamental electrical safety measure to prevent shocks. Additionally, constantly monitor water levels in the preheating and concentration tanks to avoid dry burning heating elements.

Making the Right Choice for Your Operation

Following the correct procedure consistently will protect your investment and ensure a high-quality product. Your focus will determine which step is most critical to your success.

- If your primary focus is equipment longevity: Always start the water first and stop it last. This is the best way to prevent your vacuum pump from overheating and failing prematurely.

- If your primary focus is product purity: The most critical step is to close the inlet valve before turning off the power during shutdown. This single action prevents backflow contamination.

- If your primary focus is operator safety: Your first check, every time, should be to confirm the equipment is properly grounded to eliminate electrical hazards.

By mastering this simple but rigid procedure, you ensure safe, efficient, and high-quality honey processing.

Summary Table:

| Procedure | Step 1 | Step 2 | Step 3 | Critical Goal |

|---|---|---|---|---|

| Start-Up | Open Water Supply | Turn On Power | Slowly Open Inlet Valve | Prevent pump overheating and wear |

| Shutdown | Close Inlet Valve | Turn Off Power | Close Water Source | Isolate honey tank to prevent contamination |

Protect your honey's purity and your equipment's longevity with the right supplies. Following the correct procedures is essential, and using reliable, high-performance equipment is the foundation of a successful operation. HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with the durable, wholesale-focused honey processing equipment they need to operate safely and efficiently.

Contact HONESTBEE today to discuss your specific needs and ensure your honey processing is built on a foundation of quality and reliability.

Visual Guide

Related Products

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- 0.5T Capacity Honey Dehumidifier Dryer with Vacuum Heating and Thickening Filtering Machine

- Economy Small Scale Honey Dryer Dehumidifier Thickening Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

- HONESTBEE 72 Frame Industrial Electric Honey Extractor for Beekeeping

People Also Ask

- Why is rapid homogenization necessary in the commercial collection process of Apilarnil? Preserve Bioactive Potency Now

- What are the primary technical differences between the production of raw honey and processed honey? Key Comparisons

- What is the general workflow involved in the honey production process? Master the Journey from Hive to Shelf

- How does an air circulation dryer compare to a vacuum freeze dryer? Choosing the Best Method for Drone Larvae Powder

- Why is cleaning equipment essential in honey processing? Ensure Purity and Peak Operational Efficiency

- What role does specialized processing machinery play in the development of a modern apiary workshop? Boost Scale and ROI

- Why is the implementation of professional-grade storage and processing facilities critical? Secure Your Honey Profits

- What equipment do you need to process honey? A Complete Guide for Every Scale of Operation