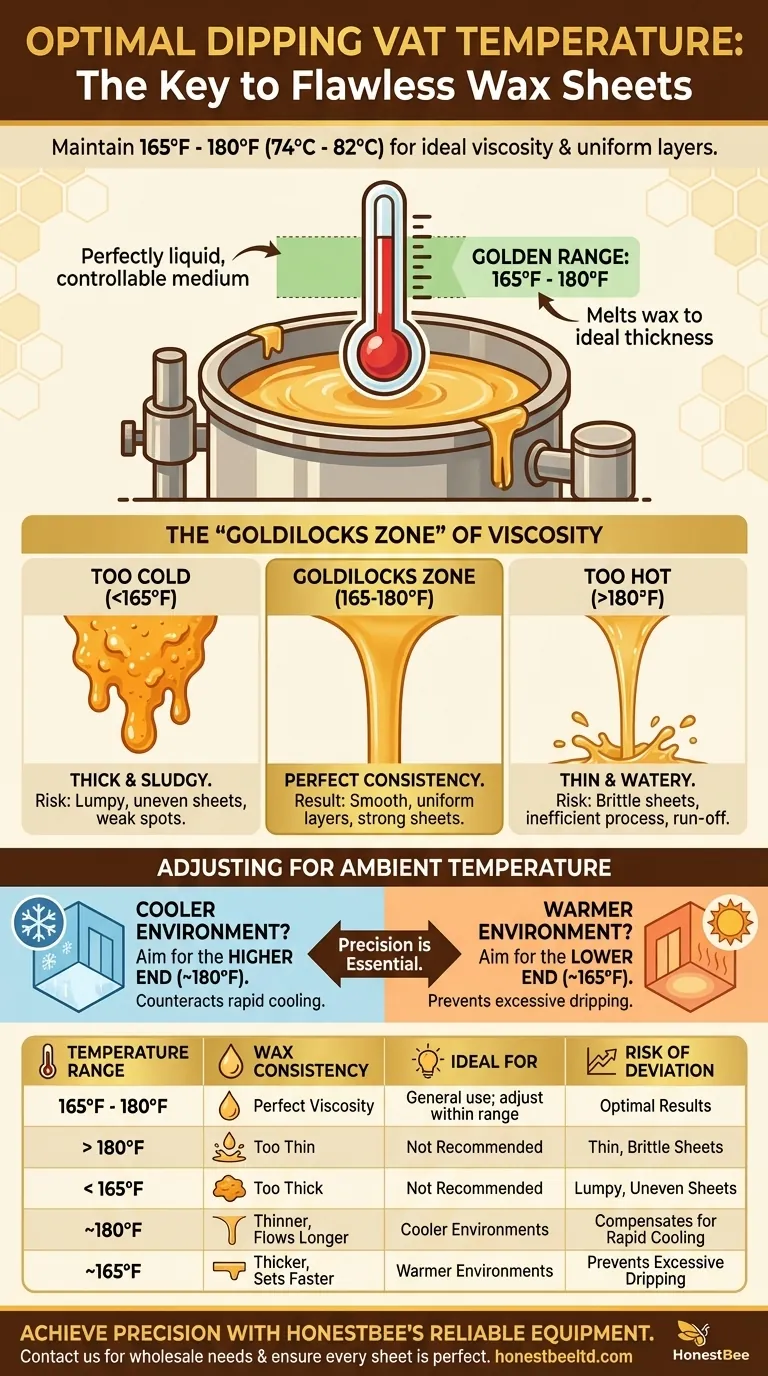

For optimal results, your dipping vat must be maintained between 165°F and 180°F (74°C to 82°C). This specific temperature range is critical because it melts the wax to the ideal viscosity, or thickness, required for building smooth, uniform sheets. The exact temperature you choose within this range will depend on the ambient temperature of your workspace.

The goal is not to simply heat the wax, but to control its consistency. The 165-180°F range provides the necessary liquidity, while adjustments within this range compensate for how quickly the wax cools in the surrounding air.

The Science of Wax Consistency

The entire dipping process hinges on creating a perfectly liquid, yet controllable, medium. The temperature of the vat is the primary lever you have to achieve this state.

Why 165-180°F is the "Goldilocks Zone"

This temperature range ensures the wax is fully liquid and free of any solid crystals, which would cause imperfections.

More importantly, it keeps the wax thin enough to coat the dipping board smoothly but thick enough to adhere and build up with successive dips. It is the ideal balance between being too runny and too sludgy.

The Goal: Building Uniform Layers

The dipping process involves repeatedly submerging a board to build up thin, even layers of wax.

If the wax consistency is correct, each dip adds a predictable, uniform layer that fuses perfectly with the one beneath it. This method is what produces a strong, consistent final sheet.

Understanding the Trade-offs: Temperature Control

Deviating from the recommended temperature range will directly compromise the quality of your sheets. Precision is not just recommended; it is essential for predictable outcomes.

The Risk of Running Too Hot (>180°F)

When the wax is too hot, its viscosity drops significantly. It becomes thin and watery.

This causes the wax to run off the board too quickly, resulting in an extremely thin layer. You will need many more dips to achieve the desired thickness, making the process inefficient. The final sheets may also be brittle.

The Risk of Running Too Cold (<165°F)

If the wax is not hot enough, it will be too thick and viscous.

As you pull the board from the vat, the wax will not flow smoothly. Instead, it can create lumps, ridges, and an uneven "orange peel" texture. These thick, semi-solid layers do not fuse well together, leading to weak spots in the final sheet.

The Critical Factor: Adjusting for Ambient Temperature

The statement that the temperature depends on "outside climatic temperature" is the key to mastering this process. The air in your workspace is constantly working to cool the wax on your board.

Working in a Colder Environment

In a cool room, the dipped board loses heat very rapidly. The wax layer solidifies almost instantly upon being pulled from the vat.

To counteract this, you should operate at the higher end of the range (closer to 180°F). The hotter wax remains liquid for a crucial few seconds longer, giving it time to flow into a smooth, even layer before it sets.

Working in a Warmer Environment

In a warm, humid room, the cooling process is much slower. The wax layer will remain liquid for longer after being removed from the vat.

To prevent the wax from being too runny and dripping off, you should operate at the lower end of the range (closer to 165°F). This slightly thicker consistency will help the wax set more quickly and predictably in the warm air.

How to Dial In Your Temperature

Your first few dips are a test. Observe how the wax behaves and adjust your vat temperature accordingly to achieve a smooth, glass-like coating on each pass.

- If your primary goal is working in a cooler climate: Start your vat near 180°F to ensure the wax flows evenly before it solidifies too quickly.

- If your primary goal is working in a warmer climate: Begin closer to 165°F to prevent the wax from being too runny and taking too long to set.

- If your primary goal is establishing a baseline: Start in the middle at 172°F, observe if the wax is too thick or too thin, and adjust up or down in small increments.

Mastering temperature control is the single most important skill for producing consistently high-quality sheets.

Summary Table:

| Temperature Range | Wax Consistency | Ideal For | Risk of Deviation |

|---|---|---|---|

| 165°F - 180°F (74°C - 82°C) | Perfect viscosity for smooth, uniform layers | General use; adjust within range based on ambient temperature | Optimal results |

| > 180°F (82°C) | Too thin and watery | Not Recommended | Thin, brittle sheets; inefficient process |

| < 165°F (74°C) | Too thick and sludgy | Not Recommended | Lumpy, uneven sheets with weak spots |

| ~180°F (82°C) | Thinner, flows longer | Cooler environments | Compensates for rapid cooling |

| ~165°F (74°C) | Thicker, sets faster | Warmer environments | Prevents excessive dripping |

Produce Flawless Foundation Sheets with Reliable Equipment from HONESTBEE

Mastering your dipping temperature is essential, but it starts with a high-quality, temperature-stable dipping vat. At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the durable, precision-engineered supplies needed for efficient, large-scale operations.

Let us help you build a stronger foundation for your business.

Contact HONESTBEE today to discuss your wholesale equipment needs and ensure every sheet you produce is perfect.

Visual Guide

Related Products

- Electric Flatting and Embossing Machine with Tray for Beekeeping

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Professional Thermostatic Conical Honey Melter

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- What is the importance of soaping the rollers during milling? Prevent Wax Adhesion & Equipment Downtime

- What are the sequential stages of operation for a beeswax flatting and embossing machine? Master High-Quality Wax Sheets

- What is the economic value of using candle-making equipment and beeswax consumables? Maximize Your Apiary Profits

- What is the primary function of a manual honeycomb embossing machine? Create Custom Beeswax Foundations with Ease

- What materials are used in a silicone beeswax foundation embossing machine? Durable Steel and Alloy Construction