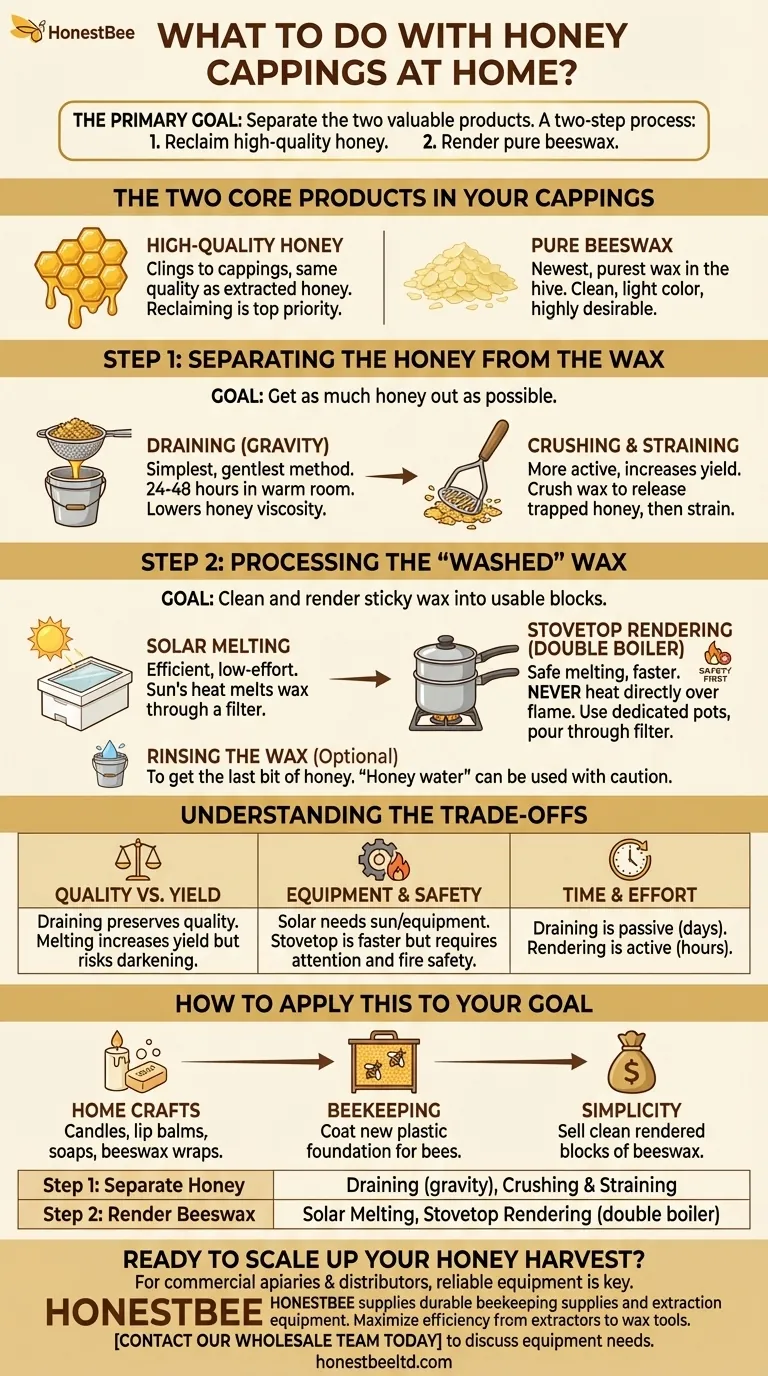

The primary goal with honey cappings is to separate the two valuable products they contain: the leftover honey and the pure beeswax. This is typically done in a two-step process at home, first by draining the honey through gravity or pressure, and then by melting and filtering the remaining wax.

Honey cappings are not waste; they are a valuable secondary harvest. The most effective home strategy involves a simple, two-stage process: first, reclaim the high-quality honey, and second, render the clean beeswax for a multitude of uses.

The Two Core Products in Your Cappings

Before processing, it's essential to understand what you're working with. Cappings are a treasure trove of two distinct and valuable hive products.

High-Quality Honey

The honey that clings to your cappings is of the same quality as the honey you just extracted. Reclaiming it is a top priority and ensures none of your hard work goes to waste.

Pure Beeswax

The wax from cappings is the newest and purest wax in the hive. Because it has not been used for brood rearing, it is clean, light in color, and highly desirable for crafting and other beekeeping uses.

Step 1: Separating the Honey from the Wax

Your first task is to get as much honey out of the wax as possible. The method you choose depends on your equipment and how much effort you want to expend.

Method 1: Draining

This is the simplest, most common, and most gentle method for your honey. It relies entirely on gravity.

Place your cappings in a coarse strainer, colander, or a nylon paint-strainer bag. Set this over a clean, food-grade bucket and cover it to keep out dust and insects.

Let the setup sit for 24 to 48 hours in a warm room. The warmth will lower the honey's viscosity, allowing more of it to drip from the wax.

Method 2: Crushing and Straining

This is a more active version of draining that can increase your honey yield.

Place the cappings in a bucket and use a clean utensil (like a potato masher) to crush and press the wax. This breaks open more of the wax cells, releasing trapped honey.

After crushing, you can either pour the mixture into your strainer setup or press it through cheesecloth to separate the honey from the wax.

Step 2: Processing the "Washed" Wax

Once most of the honey has been drained, you are left with sticky, honey-coated wax. The next step is to clean and render this wax into usable blocks.

Rinsing the Wax (Optional)

To get the last bit of honey off, you can rinse the wax in a bucket with cool water (hot water will melt it). Gently agitate the wax, then drain the water.

This "honey water" can be used to make mead or, with extreme caution regarding disease transmission, as a bee feed.

Solar Melting

A solar melter is a highly efficient, low-effort way to render wax. You can build one from a styrofoam box with a glass or plexiglass lid.

Place the washed cappings on a tray or pan inside the melter. The sun's heat will melt the wax, which then drips through a filter (like a paper towel or piece of cloth) into a collection pan below, leaving impurities behind.

Stovetop Rendering

This method uses a double boiler to melt the wax safely. Never heat beeswax directly over a flame, as it is flammable.

Place the wax in a dedicated pot that sits inside a larger pot of simmering water. As the wax melts, you can pour it through a fine filter (cheesecloth works well) into molds like silicone baking cups or old yogurt containers.

Understanding the Trade-offs

Each processing choice comes with its own set of considerations. There is no single "best" way; there is only the best way for your specific situation.

Quality vs. Yield

Gently draining the cappings preserves the highest quality of the honey but may leave a bit more behind in the wax. Melting the cappings and honey together can increase yield but risks darkening the honey and reducing its delicate flavor if overheated.

Equipment and Safety

Solar melting requires minimal supervision but needs a sunny day and a specific piece of equipment. Stovetop rendering is faster but requires constant attention, dedicated pots (wax is difficult to clean), and careful handling to avoid fire risk.

Time and Effort

Draining is a passive, "set it and forget it" process that takes a couple of days. Rendering the wax is a more hands-on activity that you can complete in a single afternoon.

How to Apply This to Your Goal

Your rendered beeswax is a fantastic resource. What you do with it depends on your primary interest.

- If your primary focus is on home crafts: Use your pure, clean wax to make candles, lip balms, lotions, soaps, or reusable beeswax food wraps.

- If your primary focus is on beekeeping: Use the rendered wax to coat new plastic foundation, making it more attractive for your bees to draw out.

- If your primary focus is on simplicity: You can sell your clean, rendered blocks of beeswax, as it is a valuable commodity for crafters and other beekeepers.

By following this two-stage process, you ensure that nothing from your harvest is wasted and every drop of honey and flake of wax is put to good use.

Summary Table:

| Step | Goal | Key Methods |

|---|---|---|

| 1 | Separate Honey | Draining (gravity), Crushing & Straining |

| 2 | Render Beeswax | Solar Melting, Stovetop Rendering (double boiler) |

Ready to scale up your honey harvest?

Processing honey cappings is just the beginning. For commercial apiaries and distributors, having reliable, high-volume equipment is key to maximizing efficiency and yield.

HONESTBEE supplies the durable beekeeping supplies and extraction equipment you need to operate at scale. We help you get the most out of every harvest, from commercial-grade extractors to wax processing tools.

Contact our wholesale team today to discuss your equipment needs and streamline your operation.

Visual Guide

Related Products

- Economy Manual Beeswax Embossing Mill Wax Foundation Machine Roller

- Electric Beeswax Foundation Machine With Operating Tray and Wax Foundation Roller

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Honey Wax Separating Wax Press with Metal Screw Wax Separator Machine

- Stainless Steel Manual Honey Press with Guard for Pressing Honey and Wax

People Also Ask

- What role does an uncapping table play in the initial stages of honey processing? Boost Your Extraction Efficiency

- How should a beekeeper set up their workspace for uncapping? Create an Efficient & Clean Harvesting Station

- What is an uncapping tank used for in honey harvesting? Maximize Your Honey Yield and Minimize Waste

- What can you do with honey cappings? Turn a Simple Byproduct into Premium Honey & Pure Beeswax

- How to use a honey settling tank? Clarify Your Honey for a Premium Finish

- Can we store honey in stainless steel container? A Guide to Safe, Bulk Honey Storage

- Why are high-performance insulated soaking tanks considered essential for label removal? Boost Glass Jar Reuse Efficiency

- How does a honey maturator or settling tank contribute to the quality of the final honey product? Enhance Clarity Now