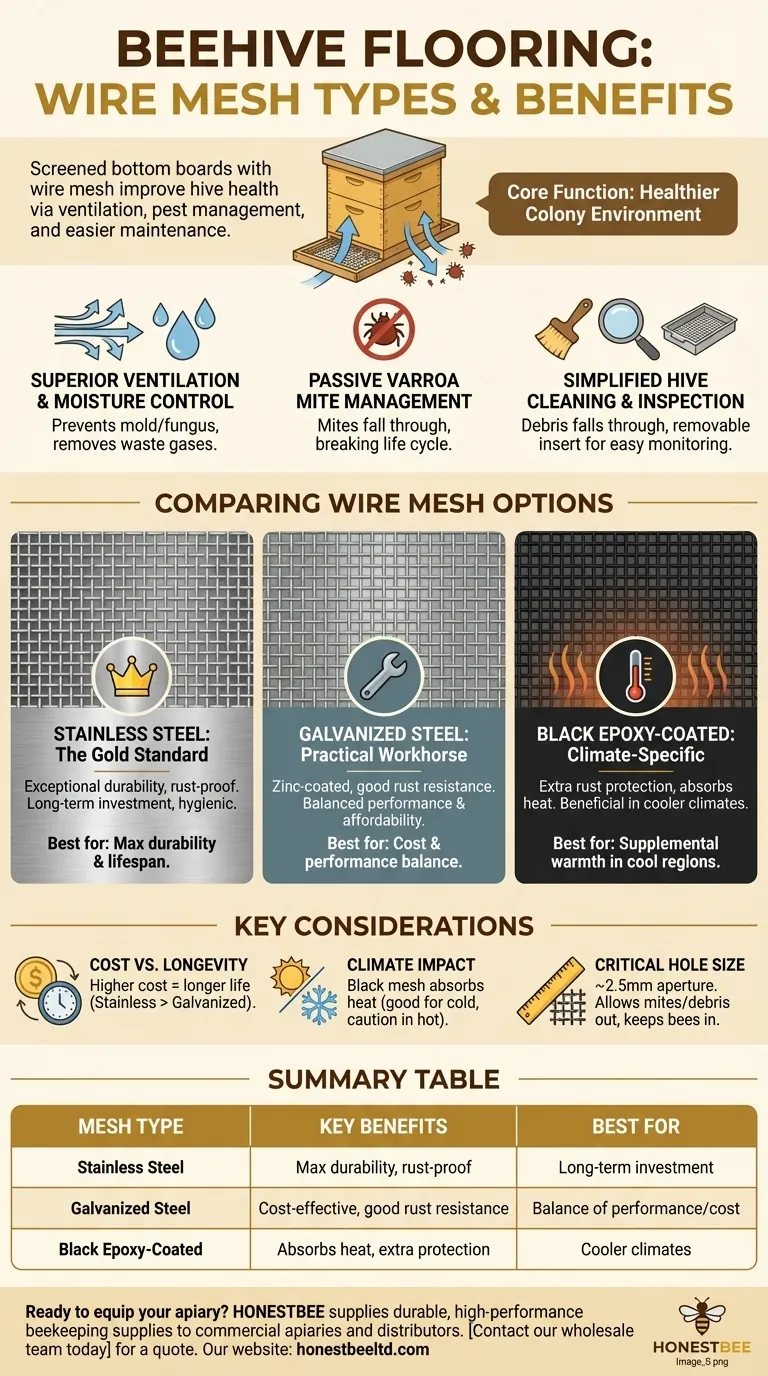

The three primary types of wire mesh used for beehive flooring are stainless steel, black epoxy-coated, and galvanized steel. Each offers a distinct set of advantages for improving hive health through better ventilation, pest management, and easier maintenance. The core function of this mesh floor, known as a screened bottom board, is to create a healthier environment for your colony.

Choosing the right wire mesh is about more than just the material; it is a strategic decision to actively manage your hive's ventilation and pests. The best choice balances long-term durability against your local climate and budget.

The Core Benefits of a Screened Bottom Board

A screened bottom board replaces the traditional solid wood floor of a hive, creating a foundation that fundamentally improves the colony's environment. This design is not merely a component; it is an active management tool.

Superior Ventilation and Moisture Control

Proper airflow is critical for a healthy hive. A mesh floor allows for constant, gentle ventilation throughout the hive.

This circulation helps prevent the buildup of excess moisture, which can lead to the growth of harmful mold and fungus. It also allows waste gases to escape, ensuring a cleaner internal atmosphere for the bees.

Passive Varroa Mite Management

The varroa mite is one of the most significant threats to honeybee colonies. A screened bottom board provides a simple yet effective defense.

When mites fall off a bee, they drop through the mesh openings and out of the hive. This prevents them from climbing back onto other bees, breaking their life cycle and reducing the overall mite population within the colony.

Simplified Hive Cleaning and Inspection

Hive maintenance becomes significantly easier with a mesh floor. Debris such as wax cappings, pollen, and dead bees naturally fall through the screen.

Most screened bottom boards include a removable solid insert or "monitoring board" below the mesh. This allows you to easily slide it out, inspect the debris for signs of hive health, and clean it off without disturbing the colony.

Comparing the Wire Mesh Options

While all mesh floors provide the core benefits, the material you choose impacts longevity, performance in specific climates, and cost.

Stainless Steel: The Gold Standard

Stainless steel is the premium choice for its exceptional durability and resistance to corrosion. It will not rust, even in damp environments, ensuring a very long service life.

While it has a higher initial cost, its longevity and ease of cleaning make it a cost-effective investment over the long term. It is the most reliable material for promoting a hygienic hive environment.

Galvanized Steel: The Practical Workhorse

Galvanized steel mesh is coated with a layer of zinc to provide good durability and rust resistance. It is a highly practical and common choice for beekeepers.

It is easier to clean and maintain than a solid wood floor and offers a great balance of performance and affordability, making it an excellent entry-point into screened bottom boards.

Black Epoxy-Coated: The Climate-Specific Choice

This type of mesh features a black epoxy coating over steel, which provides an extra layer of protection against rust.

Its key feature is the black color, which absorbs sunlight and radiates gentle heat into the hive. This can be particularly beneficial for helping the colony stay warm in cooler climates or during the spring buildup.

Understanding the Trade-offs and Key Considerations

Choosing the right mesh involves understanding the nuanced differences and how they apply to your specific goals and environment.

Cost vs. Longevity

There is a direct trade-off between upfront cost and long-term value. Galvanized mesh is the most budget-friendly, while stainless steel is the most expensive initially.

However, stainless steel will outlast galvanized mesh, which may eventually rust once the zinc coating is compromised. Your decision should factor in whether you prioritize immediate savings or a longer-lasting investment.

The Impact of Climate

The heat-absorbing property of black epoxy-coated mesh is a clear benefit in temperate or cool regions. In very hot and sunny climates, however, this same feature could contribute to overheating the hive and should be considered carefully.

The Critical Role of Hole Size

The mesh opening, or aperture, is a crucial detail. The standard recommendation is a hole size of approximately 2.5mm.

This size is large enough for varroa mites and debris to fall through but small enough to prevent bees from passing through or getting their legs caught. Using the wrong size can be ineffective or even harmful to your bees.

The Need for a Removable Insert

A screened bottom board is rarely left open to the elements year-round. It is designed to be used with a removable insert or tray.

This insert is essential for monitoring varroa mite drops, closing the hive for winter to retain heat, or temporarily reducing ventilation during specific treatments.

Making the Right Choice for Your Apiary

Your selection should be guided by your primary goals as a beekeeper.

- If your primary focus is maximum durability and long-term value: Choose stainless steel for its unmatched corrosion resistance and operational lifespan.

- If your primary focus is a balance of cost and effective performance: Galvanized steel provides reliable ventilation and pest management at a more accessible price point.

- If you are beekeeping in a cooler climate and want to provide supplemental warmth: Consider black epoxy-coated mesh for its heat absorption properties and added rust protection.

Ultimately, selecting the right mesh floor is a foundational step toward a healthier, more resilient, and easier-to-manage beehive.

Summary Table:

| Mesh Type | Key Benefits | Best For |

|---|---|---|

| Stainless Steel | Maximum durability, rust-proof, long lifespan | Beekeepers prioritizing long-term investment and hygiene |

| Galvanized Steel | Cost-effective, good rust resistance, easy maintenance | Beekeepers seeking a balance of performance and affordability |

| Black Epoxy-Coated | Absorbs heat for warmth, extra rust protection | Beekeepers in cooler climates needing supplemental hive warmth |

Ready to equip your apiary with the right screened bottom boards?

HONESTBEE supplies durable, high-performance beekeeping supplies and equipment to commercial apiaries and beekeeping equipment distributors through our wholesale-focused operations. We provide the reliable materials you need to build healthier, more manageable hives.

Contact our wholesale team today to discuss your requirements and get a quote.

Visual Guide

Related Products

- Langstroth Screen Bottom Board for Beekeeping Wholesale

- Australian Pine Wood Langstroth Screen Bottom Board for Wholesale

- Langstroth Solid Bottom Board for Beekeeping

- Professional Bamboo Queen Isolation Cage

- Black Plastic Beetle Barn Hive Beetle Trap for Beehives

People Also Ask

- Why is industrial-grade temperature and humidity monitoring equipment required for Varroa mite heat treatment processes?

- How do specialized medication applicators contribute to management of bee diseases? Precision Tools for Varroa Control

- What is the primary function of slow-release dispensers for mite control? Master Varroa Management with Precision

- What is the role of mechanical shaking washing devices with fine mesh filters in field surveys for Varroa mites?

- What is the technical purpose of using glycerin in wet Varroa mite treatments? Maximize Treatment Efficacy and Safety

- What role do Screened Bottom Boards play in the physical control of varroa mites? Boost Hive Health with Mechanical IPM

- What role does drone brood trapping play in a summer Varroa mite management strategy? Maximize Natural Mite Control

- How do Varroa mites spread between honey bee colonies? Stop Parasite Transmission in Your Apiary