Cleaning beeswax is essential to remove impurities and prepare it for use. Raw wax straight from the hive contains honey, pollen, dirt, and other debris that must be separated to create a stable, high-quality product. This process, often called rendering, ensures the final wax is pure and prevents it from fermenting or spoiling.

The core reason for cleaning beeswax is to transform a raw, contaminated hive byproduct into a valuable and stable resource. Failing to clean the wax not only compromises the quality of any products made from it but also risks the material spoiling over time due to residual honey and moisture.

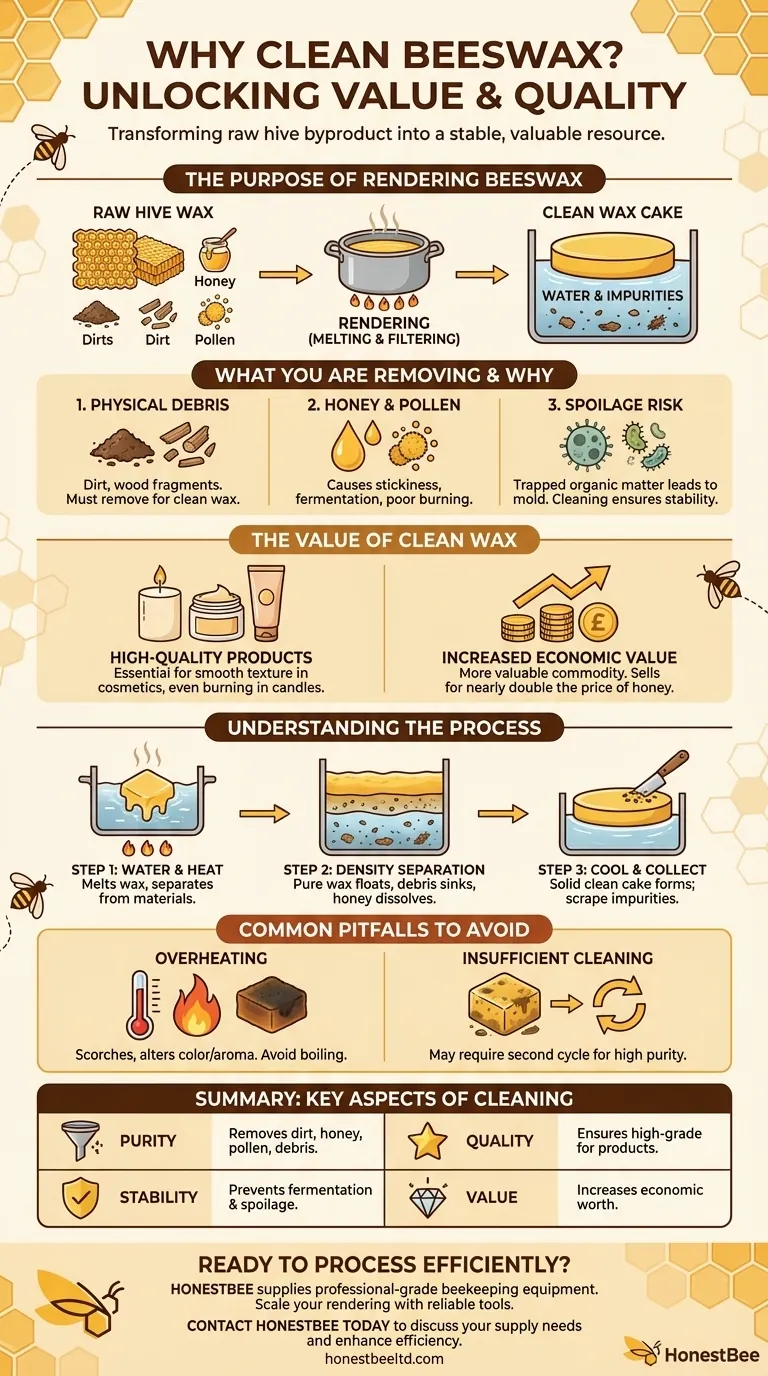

The Purpose of Rendering Beeswax

Rendering is the process of melting and filtering raw cappings and comb to separate pure wax from contaminants. Understanding what you are removing is key to appreciating the importance of the process.

Removing Physical Debris

Raw beeswax is full of physical contaminants from the hive. This can include dirt, wood fragments from the frames, and other small particles. These must be removed for the wax to be considered clean.

Eliminating Honey and Pollen

Small amounts of residual honey and pollen are always present in raw wax. While natural, honey's moisture content can lead to fermentation, and both substances can make the final wax feel sticky or burn improperly in candles.

Preventing Spoilage

The combination of honey and other organic matter trapped in the wax creates an environment where mold and bacteria can grow. Cleaning the wax by melting it with water removes these water-soluble impurities, making the final wax block stable for long-term storage.

The Value of Clean Wax

The effort of cleaning beeswax is directly rewarded by the quality and versatility of the final product. Clean wax is not only more useful but also significantly more valuable.

Creating High-Quality Products

Clean beeswax is a fundamental ingredient in countless products. Impurities would ruin the texture of cosmetics, balms, and lotions, and cause candles to smoke or burn unevenly.

Increasing Economic Value

Purified beeswax is a valuable commodity, often selling for nearly double the price of honey per pound. Whether for personal use or for sale, clean wax holds significantly more value than the raw, unrendered material.

Expanding Its Applications

The uses for clean beeswax are vast. It is used in everything from waterproofing leather and wood to lubricating tools, strengthening thread, and even in food processing.

Understanding the Basic Cleaning Process

The most common method for cleaning beeswax is simple and relies on the different densities of wax, water, and debris. This context helps clarify why the process is so effective.

Using Water and Heat

The basic technique involves melting the raw wax in water. The heat melts the wax, allowing it to separate from the other materials.

Leveraging Density Differences

Once melted, the components separate into layers. The pure beeswax is the least dense and floats to the top, while heavier debris sinks to the bottom. Water-soluble impurities like honey dissolve into the water layer.

The Result: A Clean Wax Cake

As the mixture cools, the purified wax solidifies into a clean cake on top of the water. This cake can be lifted off, and the layer of impurities at its base can be easily scraped away, leaving a block of pure, usable beeswax.

Common Pitfalls to Avoid

While the process is straightforward, a few common mistakes can compromise the quality of your final product. Being aware of them ensures a better outcome.

Overheating the Wax

Excessive heat can scorch and darken the beeswax, altering its natural color and pleasant aroma. It is crucial to melt the wax gently and avoid bringing it to a boil.

Insufficient Cleaning

For particularly dirty wax, a single rendering may not be enough. If the final wax block still has significant debris, a second cleaning cycle may be necessary to achieve the desired level of purity.

Making the Right Choice for Your Goal

The level of purity you need depends entirely on your intended use for the wax.

- If your primary focus is creating high-value cosmetics or candles: Aim for the highest purity possible, which may require filtering the wax through a fine cloth or performing the cleaning process multiple times.

- If your primary focus is personal use for rustic crafts or waterproofing: A single, thorough cleaning to remove the major debris and honey is typically sufficient.

- If your primary focus is simply storing the wax for later use: Cleaning is a mandatory first step to prevent fermentation and ensure the wax remains stable and unspoiled over time.

By properly cleaning your raw beeswax, you are transforming a simple hive byproduct into a valuable and versatile natural resource.

Summary Table:

| Key Aspect | Purpose of Cleaning |

|---|---|

| Purity | Removes dirt, honey, pollen, and debris. |

| Stability | Prevents fermentation and spoilage for long-term storage. |

| Quality | Ensures high-grade wax for candles, balms, and crafts. |

| Value | Increases economic worth; clean wax is more valuable. |

Ready to Process Your Wax Efficiently?

Cleaning beeswax is the first step to unlocking its full value. For commercial apiaries and beekeeping equipment distributors, having the right supplies is key to a smooth, profitable operation.

HONESTBEE supplies professional-grade beekeeping equipment and supplies through our wholesale-focused operations. We help you scale your rendering process with reliable tools, from wax melters to filters.

Contact HONESTBEE today to discuss your supply needs and learn how our products can enhance your wax processing efficiency and product quality.

Visual Guide

Related Products

- Electric Beeswax Flat Sheet Machine with Operating Tray for Wax Processing

- Manual Beeswax Flat Sheet Machine for Beeswax Processing

- Professional Thermostatic Conical Honey Melter

- Beehive Handle and Frame Rest Cutting Machine: Your Specialized Hive Machine

- High Quality Honey Dehumidifier Dryer Thickening Machine for Beekeeping

People Also Ask

- What are the main components of a beeswax foundation sheet machine? A Guide to Efficient Production

- Why might a commercial beekeeper prefer an electric beeswax melter? Maximize Profit with Speed & Scale

- What is the final step in making beeswax foundation sheets? Achieving Perfect Fit for a Productive Hive

- What are the steps involved in preparing wax sheets for milling? Master Temperature Control for Perfect Foundation

- What are the advantages of using industrial wax melters for beeswax? Achieve Scalable, Safe, and Consistent Production