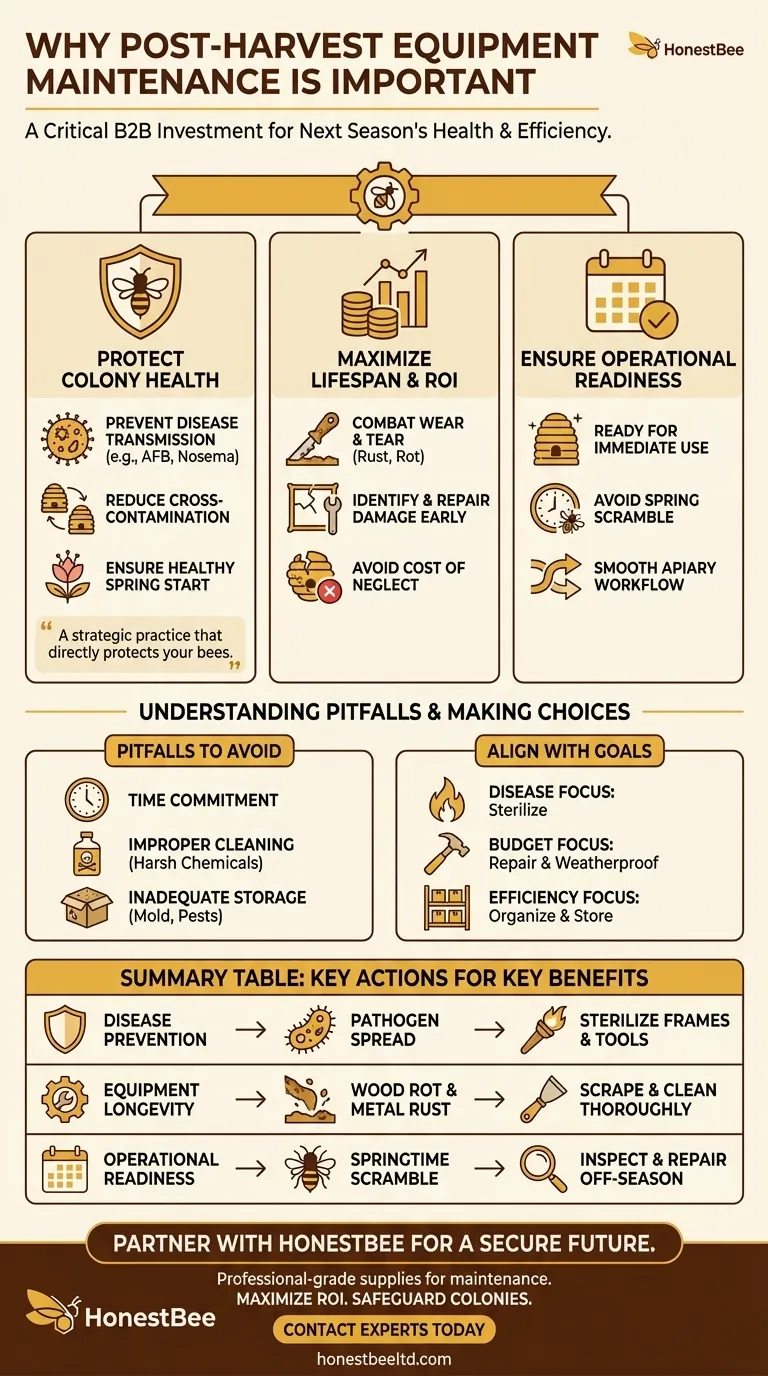

At its core, post-harvest equipment maintenance is a critical investment in the health and efficiency of your next season. It ensures your tools and hardware are clean, functional, and ready for immediate use, preventing costly malfunctions, disease transmission, and the premature degradation of your assets.

Post-harvest maintenance is not merely a cleaning chore; it is the fundamental bridge between one season's success and the next. It is a strategic practice that directly protects your bees from disease, maximizes the return on your equipment investment, and ensures operational readiness when it matters most.

Protecting the Health of Your Colonies

The most significant risk of improper maintenance is introducing or spreading disease. Leftover honey, pollen, and propolis can be vectors for devastating pathogens.

Preventing Disease Transmission

Pathogens like American Foulbrood (AFB) spores, chalkbrood, and Nosema can survive for long periods in old comb and on uncleaned equipment. Thorough cleaning and sterilization break this cycle of infection, safeguarding your bees.

Reducing Cross-Contamination

Using a dirty hive tool or moving uncleaned frames between hives is a primary way to spread problems, such as a varroa mite infestation, from a weaker colony to a strong one. Proper sanitation protocols isolate issues before they become apiary-wide crises.

Ensuring a Healthy Start Next Season

When you provide a colony with clean boxes and frames in the spring, they can dedicate their energy to building new comb, raising brood, and gathering resources. They are not forced to waste precious time and energy cleaning or fighting off legacy pathogens left from the previous year.

Maximizing Equipment Lifespan and ROI

Beekeeping equipment is a significant financial investment. Maintenance is the most effective way to protect that investment and maximize its return over time.

Combating Wear and Tear

Residual honey and moisture are primary causes of degradation. They can cause rust to form on metal extractors and tools, and encourage wood rot and mold growth on hive bodies and supers. Scraping and cleaning remove these corrosive agents.

Identifying Damage Early

The post-harvest teardown and cleaning process is the ideal time for a thorough inspection. You can identify and set aside cracked boxes, broken frames, or warped covers for repair or replacement during the quiet off-season, preventing a scramble during a spring swarm.

The Financial Cost of Neglect

The cost of replacing a rotten hive body or a diseased colony far exceeds the time and effort required for proper maintenance. Viewing this work as asset protection, not just a chore, reframes its value entirely.

Understanding the Pitfalls

While essential, the maintenance process itself has potential challenges that must be managed correctly to be effective.

The Time Commitment

Properly scraping, cleaning, repairing, and storing equipment for an entire apiary is a significant time investment. This task must be factored into your annual workflow.

Using Improper Cleaning Methods

Using harsh chemical cleaners or pesticides can be counterproductive. These substances can be absorbed by the wood and wax, potentially harming or killing the bees next season. Always use bee-safe methods like scorching with a blowtorch or washing with a soda solution.

Inadequate Storage

Even perfectly cleaned equipment can be ruined by improper storage. Storing frames and boxes in a damp, dark location encourages mold and mildew, while failing to protect them from pests can lead to a devastating wax moth infestation. Equipment should be stored in a dry, well-ventilated, and pest-proof location.

Making the Right Choice for Your Goal

Your specific maintenance priorities should align with your primary operational goals for the coming year.

- If your primary focus is disease prevention: Prioritize the sterilization of all equipment, especially if you have dealt with foulbrood, chalkbrood, or high mite counts.

- If your primary focus is maximizing your budget: Concentrate on thoroughly scraping, repairing, and weather-proofing all woodenware to extend its service life for as many seasons as possible.

- If your primary focus is next-season efficiency: Organize and store your equipment so it is immediately deployable for swarm catching, hive splits, or supering in the spring.

By treating post-harvest maintenance as a strategic opportunity, you transform an end-of-season chore into your first decisive step toward a successful year ahead.

Summary Table:

| Key Benefit | Key Risk of Neglect | Key Action |

|---|---|---|

| Disease Prevention | Pathogen Spread (e.g., AFB) | Sterilize Frames & Tools |

| Equipment Longevity | Wood Rot & Metal Rust | Scrape & Clean Thoroughly |

| Operational Readiness | Springtime Scramble | Inspect & Repair Off-Season |

Protect your apiary's future with professional-grade supplies from HONESTBEE.

Proper maintenance starts with durable, reliable equipment. As a trusted wholesale supplier for commercial apiaries and distributors, we provide the high-quality tools you need to efficiently clean, repair, and store your gear—maximizing your ROI and safeguarding your colonies.

Contact our expert team today to discuss your supply needs and ensure your operation is ready for a productive season ahead.

Visual Guide

Related Products

- Stainless Steel Double Sided Honey Uncapping Fork with Scraper

- Extra Wide Stainless Steel Honey Uncapping Fork with Scraper Beekeeping Tool

- Wide Adjustable Stainless Steel Honey Uncapping Fork with Scraper

- Stainless Steel Dual Blade Uncapping Plane

- Honeycomb Uncapping Knife for Apiculture

People Also Ask

- Why are my bees not capping honey? Understand the Key to Perfect Honey Ripening

- How can an uncapping fork be used to encourage bees to relocate honey within a hive? Master Resource Management

- What are the characteristics of the combined uncapping fork and scraper tool? Maximize Hive Maintenance Efficiency

- What other tools are available for honey uncapping besides knives? Find the Right Tool for Your Apiary's Scale

- What makes polyurethane foam environmentally friendly? The Surprising Benefits of a Durable, Inert Material