Wax dipping is considered superior to painting for bee equipment because it impregnates the wood with a protective blend of waxes, offering deeper and longer-lasting protection than a simple surface coat of paint. This process effectively seals the wood from moisture from the inside out, preventing rot and significantly extending the equipment's lifespan while maintaining the wood's natural appearance.

While painting creates a film on the wood's surface that can crack, peel, and trap moisture, wax dipping forces a protective wax blend deep into the wood grain. This creates a durable, breathable barrier that drastically reduces long-term maintenance and extends the life of your equipment.

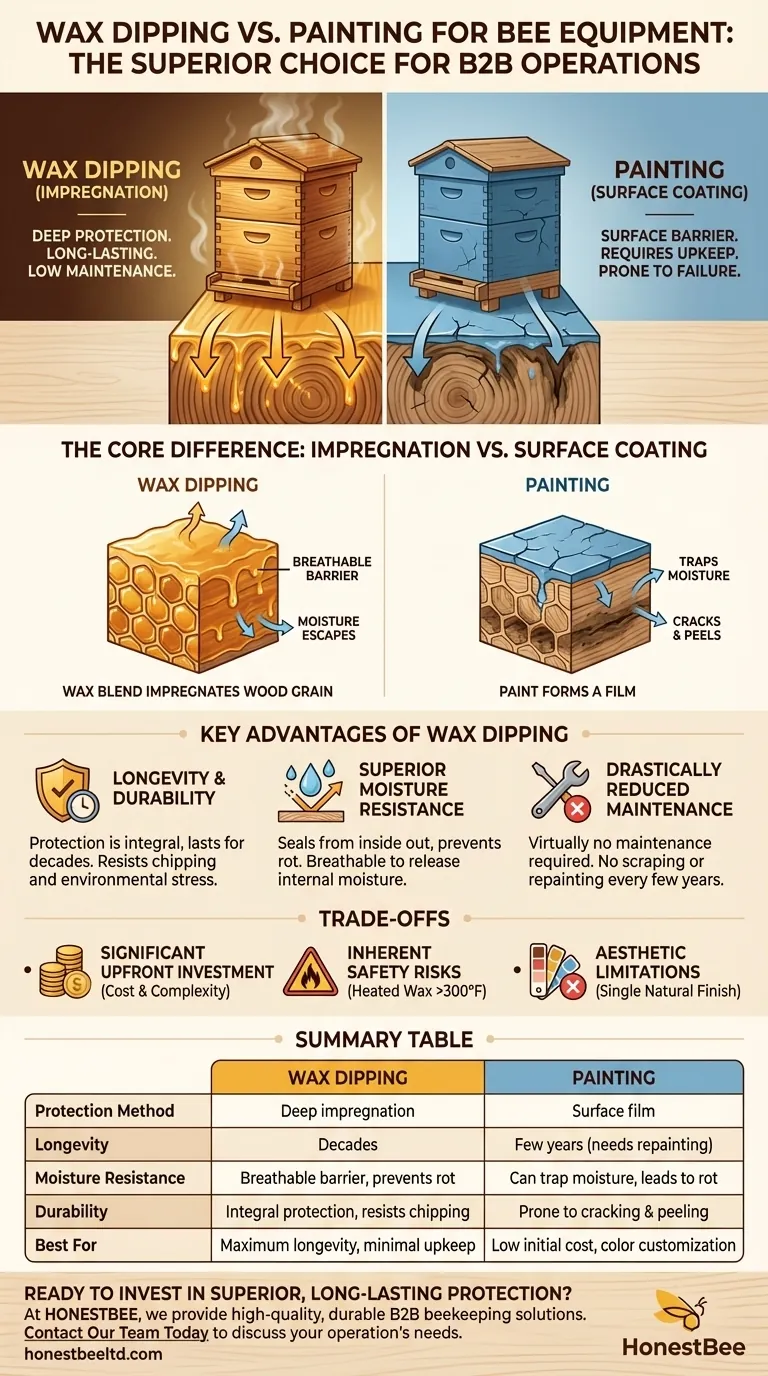

The Core Difference: Impregnation vs. Surface Coating

To understand the advantage of wax dipping, you must first understand how each method protects the wood. The two approaches are fundamentally different.

How Painting Works

Paint forms a film that sits on top of the wood. It acts as a barrier between the wood and the elements.

This film is effective as long as it remains perfectly intact. However, it is prone to cracking, chipping, and peeling over time due to sun and moisture exposure.

How Wax Dipping Works

Wax dipping involves submerging wooden components in a vat of heated paraffin and microcrystalline wax. The high temperature allows the wax to penetrate deep into the wood's fibers.

As the wood cools, the wax solidifies within the grain. This makes the protection an integral part of the wood itself, not just a layer on top.

The Critical Breathability Factor

Wood naturally expands and contracts, and it needs to "breathe" to release any internal moisture.

Paint can trap moisture behind its film. If water gets in through a small crack, the paint prevents it from evaporating, which accelerates wood rot. Waxed wood, however, remains breathable, allowing moisture to escape and preventing decay.

The Longevity and Durability Advantage

The deep impregnation of wax provides a clear advantage in the harsh environments where beehives operate.

Resisting the Elements

The specialized blend of paraffin and microcrystalline wax is designed to withstand all weather climates without breaking down.

Unlike paint, this wax blend will not become brittle and crack in the sun or peel after freeze-thaw cycles. The protection remains stable and effective for years.

Protection from the Inside Out

Since the protection is in the wood, it cannot be scraped off or compromised by minor surface damage. This ensures the entire piece of equipment remains protected even with the normal wear and tear of beekeeping.

Drastically Reduced Maintenance

Painted hives typically require scraping and repainting every few years to maintain their protective barrier. A properly wax-dipped hive can last for decades with virtually no maintenance required.

Understanding the Trade-offs

While wax dipping is superior in terms of protection, it is not without its challenges. Objectivity requires acknowledging its limitations.

Significant Upfront Investment

The primary barrier to wax dipping is the initial cost and complexity. It requires a large heated vat and a substantial quantity of wax, which is a far greater investment than a can of paint and a brush.

Inherent Safety Risks

Working with a large volume of wax heated to over 300°F (150°C) is inherently dangerous. It demands strict safety protocols, proper protective equipment, and a controlled environment to prevent serious burns or fire.

Aesthetic Limitations

Paint offers unlimited color options, which many beekeepers use to decorate or color-code their hives. Wax dipping results in a single, beautiful finish that darkens the wood's natural grain. If custom colors are a priority, painting is the only option.

Making the Right Choice for Your Operation

Your decision should be based on your scale, budget, and long-term goals.

- If your primary focus is maximum longevity and minimal maintenance: Wax dipping is the undisputed best choice for protecting your investment over decades.

- If your primary focus is low initial cost and simple application: Painting is a viable, accessible option, but be prepared for the recurring labor of regular upkeep.

- If your primary focus is bee health and creating a natural environment: Wax dipping is ideal, as it avoids the Volatile Organic Compounds (VOCs) found in many paints.

By understanding the fundamental difference between a surface coating and deep preservation, you can confidently choose the method that best aligns with your beekeeping philosophy.

Summary Table:

| Feature | Wax Dipping | Painting |

|---|---|---|

| Protection Method | Deep impregnation into wood grain | Surface coating/film |

| Longevity | Decades with minimal maintenance | Requires repainting every few years |

| Moisture Resistance | Breathable barrier prevents rot | Can trap moisture, leading to rot |

| Durability | Protection is integral; resists chipping | Prone to cracking, chipping, and peeling |

| Best For | Maximum longevity, minimal upkeep | Low initial cost, color customization |

Ready to invest in superior, long-lasting protection for your apiary?

At HONESTBEE, we understand that commercial beekeepers and equipment distributors need durable, low-maintenance solutions to protect their investments. Our wholesale-focused operations provide the high-quality supplies you need to succeed.

Contact our team today to discuss how our beekeeping equipment and expertise can benefit your operation.

Visual Guide

Related Products

- HONESTBEE Professional Long Handled Hive Tool with Precision Cutting Blade

- HONESTBEE Advanced Ergonomic Stainless Steel Hive Tool for Beekeeping

- Professional Dual-End Stainless Steel Hive Tool for Beekeeping

- Wholesales Dadant Size Wooden Bee Hives for Beekeeping

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

People Also Ask

- How can natural beeswax be purified after being removed from a hive? Master the Wax Rendering Process

- Why is the separation of waste wax slag critical for bee product safety? Manage Radiological Risks Effectively

- How can beeswax value-addition processes be utilized to increase beekeeping revenue? Boost Your Apiary Profitability

- Why should dark and light combs be processed separately? Maximize Purity & Value of Your Beeswax

- How does a solar-powered frame wax melter work? Harness the Sun for Sustainable Beekeeping

- How does mechanized beeswax processing equipment contribute to resource recovery? Maximize Profit & Hive Efficiency

- How does a solar wax extractor function to separate beeswax? Efficient Natural Purification for Pure Wax

- How does temperature-controlled processing equipment ensure the quality of beeswax products? Safeguard Your Craft