Understanding the biochemical mechanisms behind honey preservation isn't just academic—it directly impacts flavor, texture, and health benefits. Proper storage can maintain honey's natural enzymes and antioxidants for years, while mistakes accelerate degradation. This guide reveals the science-backed strategies commercial apiaries use to protect honey quality long-term.

The Chemistry of Honey Preservation

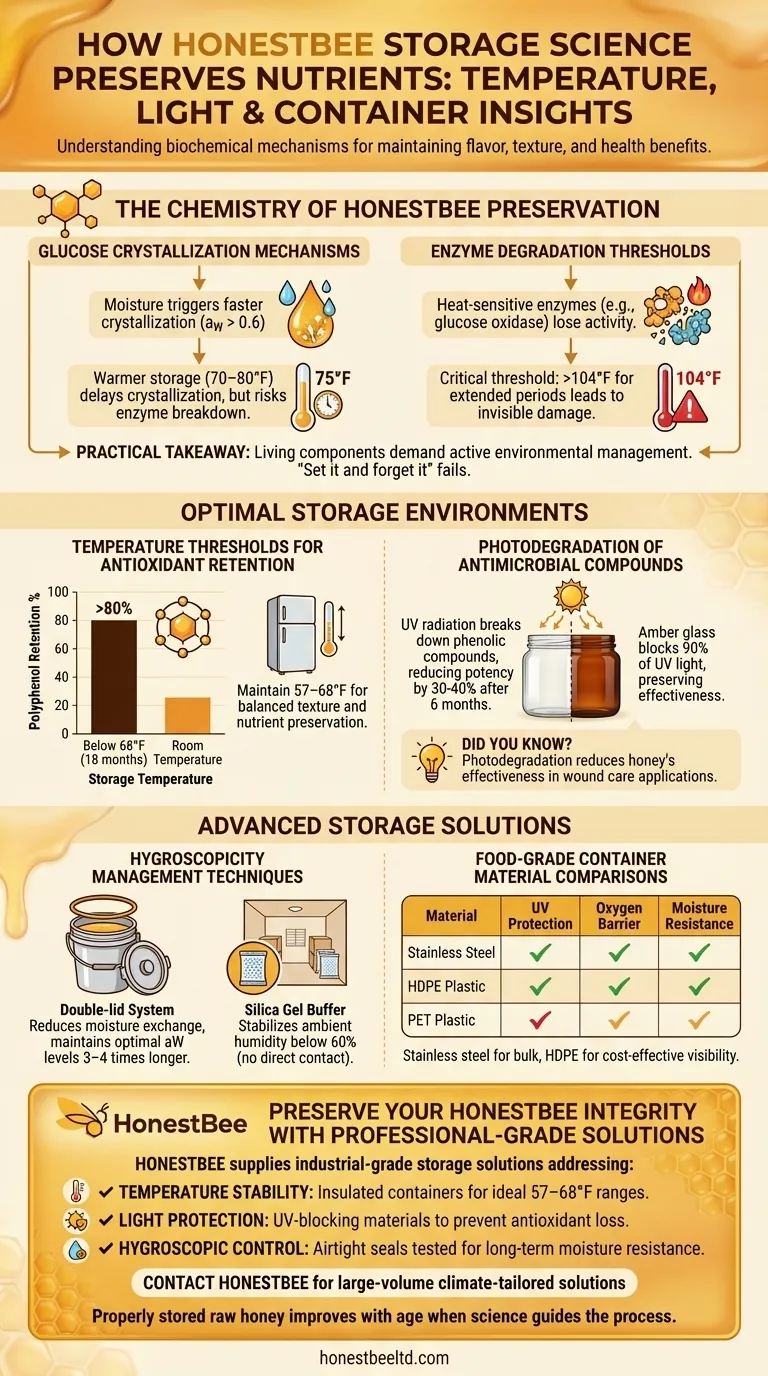

Honey's longevity stems from its unique biochemical composition, but two processes threaten quality over time: glucose crystallization and enzyme degradation.

Glucose Crystallization Mechanisms

All raw honey crystallizes eventually, but storage conditions dictate the speed and texture of this process:

- Moisture triggers faster crystallization: When water activity (aW) levels rise above 0.6, honey absorbs ambient humidity, creating ideal conditions for glucose molecules to form crystals. Beekeepers observe this when honey stored in humid environments develops grainy textures within months rather than years.

- Temperature's dual role: Cooler temperatures (50–60°F) slow microbial growth but accelerate crystallization. Warmer storage (70–80°F) delays crystallization but risks enzymatic breakdown.

Enzyme Degradation Thresholds

The enzymes that give honey its antimicrobial properties—like glucose oxidase—are heat-sensitive:

- Critical threshold: Research shows enzyme activity drops significantly when honey exceeds 104°F for extended periods.

- Invisible damage: Unlike crystallization, enzyme loss doesn't change honey's appearance, making proper storage vital for maintaining therapeutic benefits.

Practical takeaway: The "set it and forget it" approach fails with honey. Its living components demand active environmental management.

Optimal Storage Environments

Commercial apiaries preserve honey quality by controlling two often-overlooked factors: temperature fluctuations and light exposure.

Temperature Thresholds for Antioxidant Retention

- Polyphenol protection: Studies indicate honey stored below 68°F retains over 80% of its antioxidants after 18 months, while samples kept at room temperature show notable declines.

- Freezing considerations: While freezing prevents crystallization, it can alter honey's viscosity. For bulk storage, maintaining 57–68°F balances texture and nutrient preservation.

Photodegradation of Antimicrobial Compounds

Honey's hydrogen peroxide content—key to its antibacterial properties—diminishes under light exposure:

- UV radiation effect: Transparent containers allow UV wavelengths to break down phenolic compounds. After six months in clear glass, honey may lose 30–40% of its antimicrobial potency compared to opaque storage.

- Amber glass advantage: Laboratory tests show amber glass blocks 90% of UV light, outperforming plastic and clear glass.

Did you know? The same photodegradation process that bleaches honey also reduces its effectiveness in wound care applications.

Advanced Storage Solutions

Large-scale honey preservation requires addressing hygroscopicity (moisture absorption) and material compatibility—challenges familiar to commercial operators.

Hygroscopicity Management Techniques

- Double-lid systems: Food-grade buckets with inner gaskets and outer locking lids reduce moisture exchange. In humidity-controlled trials, this setup maintained optimal aW levels 3–4 times longer than single-lid containers.

- Silica gel buffers: Some apiaries place desiccant packs in storage rooms (never direct contact with honey) to stabilize ambient humidity below 60%.

Food-Grade Container Material Comparisons

| Material | UV Protection | Oxygen Barrier | Moisture Resistance |

|---|---|---|---|

| Stainless Steel | Excellent | Excellent | Excellent |

| HDPE Plastic | Moderate | Good | Good |

| PET Plastic | Poor | Fair | Fair |

Stainless steel excels for bulk storage but limits visibility. HDPE offers a cost-effective balance for distributors needing to inspect honey without opening containers.

Preserve Your Honey's Integrity with Professional-Grade Solutions

Honey's complex biochemistry demands storage systems designed for its unique properties. HONESTBEE supplies commercial apiaries and distributors with industrial-grade storage solutions that address:

✔ Temperature stability – Insulated containers to maintain ideal 57–68°F ranges

✔ Light protection – UV-blocking materials to prevent antioxidant loss

✔ Hygroscopic control – Airtight seals tested for long-term moisture resistance

For beekeeping operations prioritizing honey quality from hive to shelf, explore our wholesale-focused storage systems engineered to preserve enzymatic activity and delay crystallization. Contact HONESTBEE to discuss large-volume solutions tailored to your climate.

Final thought: In an era of processed sweeteners, properly stored raw honey remains one of the few foods that improves with age—when science guides the preservation process.

Visual Guide

Related Products

- Hexagonal Glass Honey Jars with Metal Lug Caps Elegant Versatile Packaging

- Classic Drum Shaped Glass Honey Jar with Airtight Lid

- Inverted Squeezable Honey Jar with No Drip Flip Top Cap for Easy Pouring

- 10L Stainless Steel Electric Honey Press Machine

- Professional Cone-Shaped Honey Filter with Reinforced Steel Ring

Related Articles

- How to Safely Restore Crystallized Honey Without Losing Nutrients

- Raw Honey vs. Processed Honey: Evidence-Based Health Benefits Compared

- How to Prevent Honey Fermentation: The Science of Moisture Control for Beekeepers

- How to Preserve Honey's Nutrients Without Heat: Science-Backed Methods

- How Honey Bottle Designs Combine Convenience, Safety, and Sustainability