For honey producers, selecting the right filling equipment is a pivotal decision that impacts both financial health and operational efficiency. Whether you're an artisan beekeeper or a large-scale processor, understanding the trade-offs between semi-automatic and fully automatic honey fillers ensures your investment aligns with production goals. This guide breaks down cost structures, scalability, and technological advancements to help you make an informed choice.

Semi-Automatic vs. Fully Automatic Honey Fillers: Key Comparisons

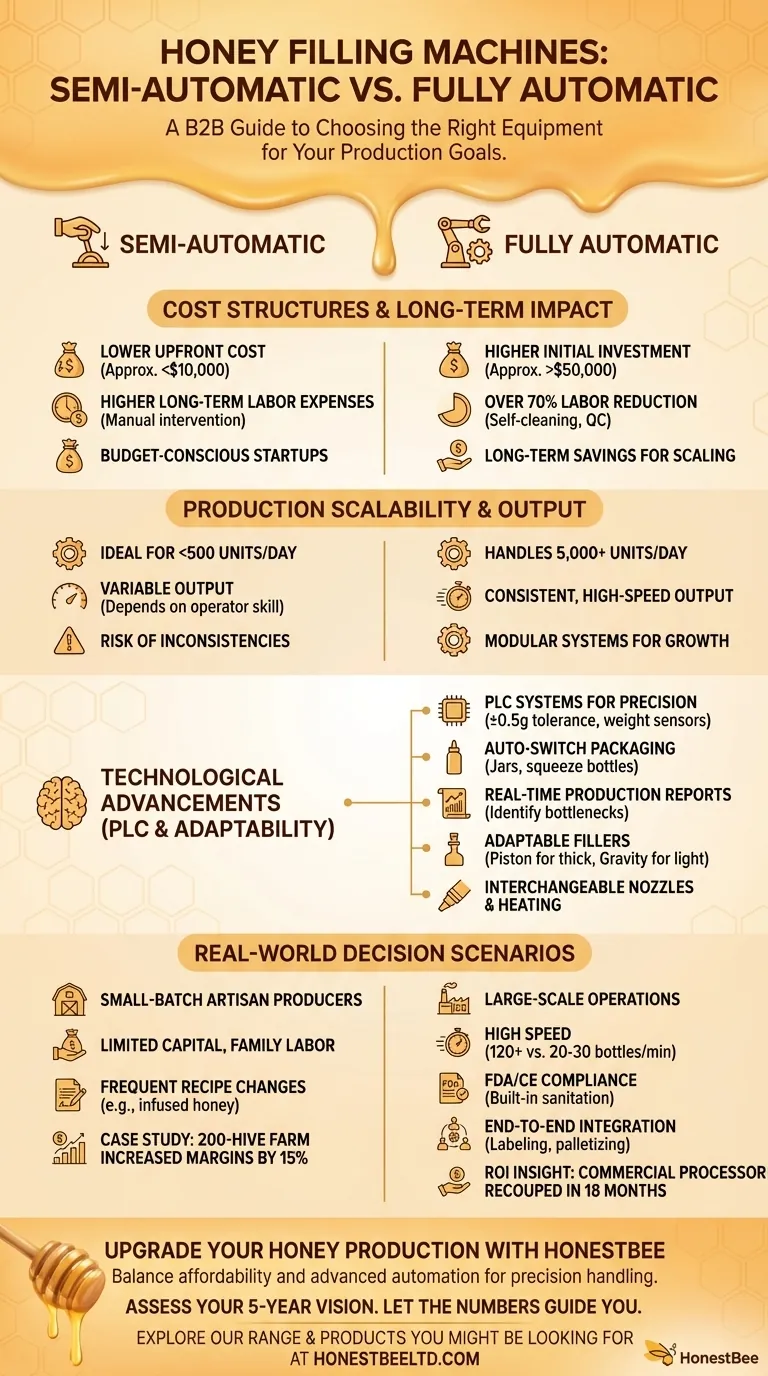

Cost Structures and Long-Term Financial Impact

Semi-automatic machines offer lower upfront costs (typically under $10,000), making them accessible for small producers. However, they require manual intervention for tasks like bottle placement and cap sealing, increasing labor expenses over time.

Fully automatic systems demand higher initial investment (often exceeding $50,000) but reduce labor needs by over 70%. Their self-cleaning mechanisms and integrated quality control also minimize product waste—critical for high-volume operations.

Key Takeaway: Semi-automatic fillers suit budget-conscious startups, while fully automatic models deliver long-term savings for scaling businesses.

Production Scalability and Output Consistency

- Semi-automatic: Ideal for batches under 500 units/day. Output varies with operator skill, risking inconsistencies in fill levels.

- Fully automatic: Handles 5,000+ units/day with

Decision Tip: If you plan to expand production within 2–3 years, investing in modular automatic systems avoids costly equipment replacements.

Technological Advancements in Automation

Role of PLC Systems in Precision and Labor Reduction

Modern fully automatic fillers use PLCs to:

- Monitor fill accuracy (±0.5g tolerance) via weight sensors.

- Auto-switch between packaging formats (jars, squeeze bottles).

- Generate real-time production reports to identify bottlenecks.

Example: A mid-sized apiary using PLC-driven fillers reduced downtime by 30% by predicting maintenance needs.

Adaptability to Different Honey Types and Packaging

Thicker honey (e.g., manuka) works best with piston fillers, while gravity fillers suit lighter varieties. Fully automatic machines often include interchangeable nozzles and heating elements to handle diverse textures without manual reconfiguration.

Real-World Applications and Decision Scenarios

Small-Batch Artisan Producers: When Semi-Automatic Makes Sense

- Budget: Limited capital for equipment.

- Labor: Family-run teams can manage manual steps.

- Flexibility: Frequent recipe changes (e.g., infused honeys) are easier with hands-on control.

Case Study: A 200-hive farm increased margins by 15% using a semi-automatic piston filler for small-batch seasonal products.

Large-Scale Operations: Maximizing ROI with Full Automation

- Speed: Filling 120+ bottles/minute vs. 20–30 on semi-automatic.

- Compliance: Built-in sanitation meets FDA/CE standards for export markets.

- Integration: Syncs with labeling and palletizing systems for end-to-end automation.

ROI Insight: A commercial processor recouped its automatic filler investment in 18 months through reduced wage costs and higher throughput.

Upgrade Your Honey Production with HONESTBEE

Whether you’re a beekeeping distributor supplying commercial apiaries or a growing honey brand, HONESTBEE’s filling solutions balance affordability and advanced automation. Explore our range to find equipment that scales with your business—because every drop of honey deserves precision handling.

Final Thought: Your ideal machine isn’t just about today’s output; it’s about fueling tomorrow’s growth. Assess your 5-year vision, then let the numbers guide you.

Products You Might Be Looking For:

View budget-friendly semi-automatic honey fillers

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Durable Efficient HONESTBEE Rotary Honey Filling Machine

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine