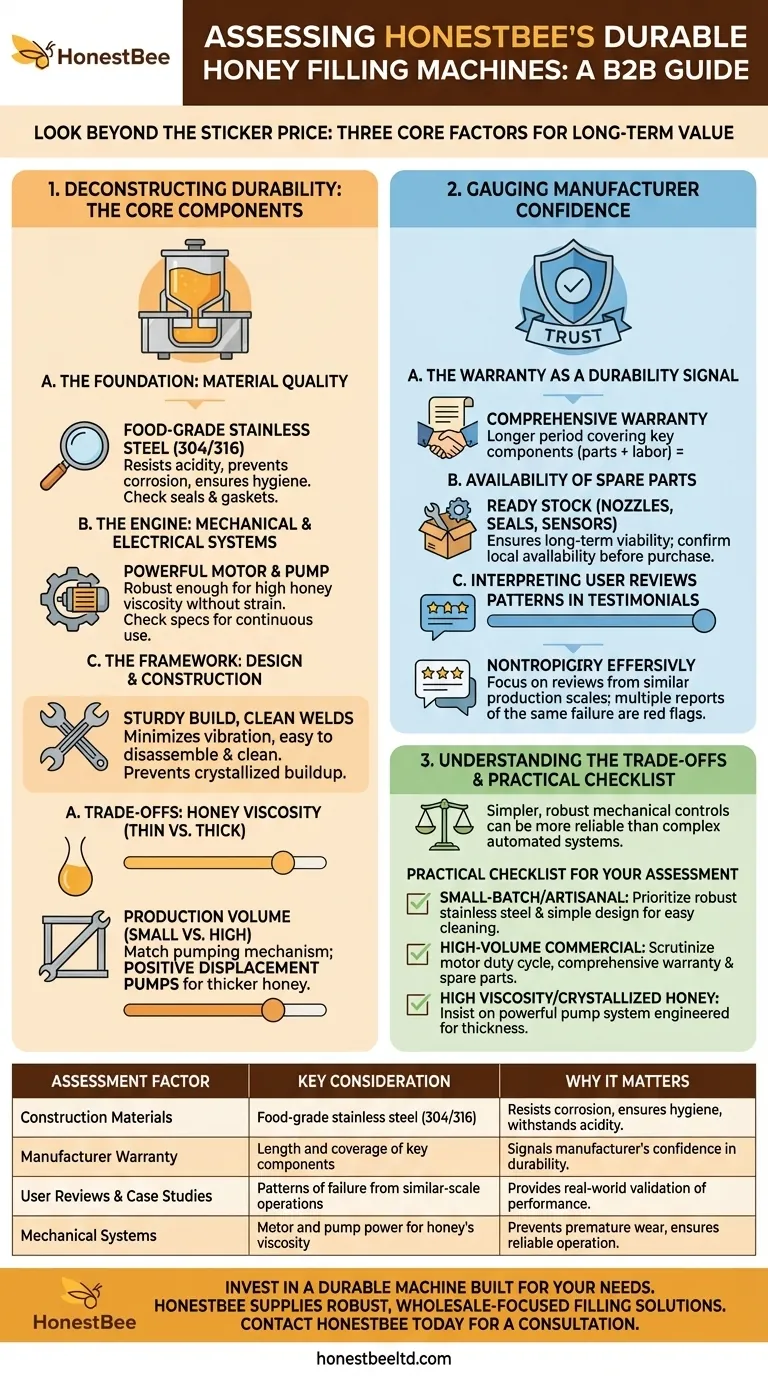

To assess the durability of a honey filling machine, you must look beyond the sticker price and evaluate three core factors. The assessment begins with the quality of the construction materials, extends to the manufacturer's confidence as reflected in their warranty, and is validated by the real-world experiences found in user reviews and case studies.

The true measure of a honey filling machine's durability isn't just how long it lasts, but how reliably it performs under the specific stress of your production needs. A truly durable machine is a combination of robust materials, strong manufacturer support, and a design that is well-suited to the viscosity of your honey and your operational volume.

Deconstructing Durability: The Core Components

A machine's lifespan is determined by the quality of its individual parts and the intelligence of its design. A weakness in any single area can compromise the entire system.

The Foundation: Material Quality

The primary material you should look for is food-grade stainless steel, typically grades 304 or 316. This is non-negotiable for any parts that come into contact with the honey.

This material resists the slight acidity of honey, prevents corrosion, and ensures hygienic operation. Also, inspect the quality of seals and gaskets, as these are common failure points.

The Engine: Mechanical and Electrical Systems

The durability of the internal components is just as critical as the external frame. The motor and pump system must be robust enough to handle the high viscosity of honey without strain.

Inquire about the specifications of these core components. A machine with an underpowered motor will experience premature wear and failure when used for continuous or high-volume production.

The Framework: Design and Construction

Examine the overall build quality. Look for clean, strong welds and a sturdy frame that minimizes vibration during operation.

A well-designed machine is also easy to disassemble and clean. This isn't just about hygiene; it prevents the long-term buildup of crystallized honey that can strain mechanical parts.

Beyond the Machine: Gauging Manufacturer Confidence

How a manufacturer supports its product is a powerful indicator of its expected durability and your long-term experience.

The Warranty as a Durability Signal

A comprehensive warranty is a direct statement of the manufacturer's confidence in their engineering. A longer warranty period, especially one that covers key mechanical components, suggests a more durable build.

Be sure to understand what is covered. A one-year warranty on parts is very different from a one-year warranty that also includes labor and service.

Availability of Spare Parts

Even the most durable machine will eventually need maintenance. The long-term viability of your investment depends on the ready availability of spare parts like nozzles, seals, and sensors.

Before purchasing, confirm that the manufacturer or a local distributor maintains a stock of common replacement parts. A machine can be rendered useless by a single, unavailable component.

Interpreting User Reviews

Look for patterns in online reviews and testimonials. A single negative review may be an outlier, but multiple reports of the same component failing (e.g., a pump motor or a control panel) are a significant red flag.

Focus on reviews from businesses with a production scale similar to your own to get the most relevant insights.

Understanding the Trade-offs

A machine isn't just durable or not durable in a vacuum; its longevity is directly tied to whether it's the right tool for the job.

The Impact of Honey Viscosity

Forcing a machine designed for thin liquids to handle thick, viscous, or crystallized honey is the fastest way to destroy its motor and pump.

You must match the machine's pumping mechanism to your product. Powerful positive displacement pumps are essential for thicker honey and will last far longer under that specific stress.

Production Volume and Duty Cycle

A machine built for small, intermittent batches will not withstand the demands of an eight-hour, continuous production day.

Be clear about your expected production volume. Choosing a machine with a duty cycle rated for your operational intensity is critical for ensuring its long-term durability.

The Cost of Simplicity

Sometimes, a less complex machine is a more durable one. Advanced automated systems with numerous sensors and delicate electronic controls can introduce more potential points of failure.

For smaller operations, a simpler, semi-automatic machine with robust mechanical controls may prove to be a more reliable long-term investment.

A Practical Checklist for Your Assessment

To make the right choice, align the machine's capabilities with your specific operational goals.

- If your primary focus is small-batch, artisanal production: Prioritize robust, food-grade stainless steel construction and simplicity of design for easy cleaning over high-speed automation.

- If your primary focus is high-volume commercial operation: Scrutinize the motor's duty cycle rating, the comprehensiveness of the warranty, and the manufacturer's spare parts program.

- If you work with highly viscous or crystallized honey: Insist on a machine with a powerful pump system specifically engineered for thick products to prevent premature burnout.

Choosing the right machine is an investment in your operational future, and a durable machine is the foundation of consistent, reliable production.

Summary Table:

| Assessment Factor | Key Consideration | Why It Matters |

|---|---|---|

| Construction Materials | Food-grade stainless steel (304/316) | Resists corrosion, ensures hygiene, and withstands acidic honey. |

| Manufacturer Warranty | Length and coverage of key components | Signals the manufacturer's confidence in the machine's durability. |

| User Reviews & Case Studies | Patterns of failure from similar-scale operations | Provides real-world validation of performance and longevity. |

| Mechanical Systems | Motor and pump power for honey's viscosity | Prevents premature wear and ensures reliable operation. |

Invest in a durable honey filling machine built for your specific needs.

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with robust, wholesale-focused filling solutions. Our machines are engineered with high-grade materials and powerful pumps to handle your production volume and honey viscosity, ensuring long-term reliability and maximizing your operational uptime.

Contact HONESTBEE today for a consultation to find the right, durable machine for your business.

Visual Guide

Related Products

- Semi Automatic Small Honey Bottle Filling Machine Honey Filler

- Double Nozzle Small Honey Filling Machine Honey Sachet Packing Packaging Equipment

- Manual Honey Filling Machine Bottling Machine for Honey

- Automatic Honey Filling and Filtering Machine for Beekeeping Bottle Filling

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

People Also Ask

- What contribution does automatic honey filling and processing machinery make to the honey industry's value enhancement?

- What is the importance of honey filling machines? Scale Your Production and Ensure Product Integrity

- How can Arrhenius model parameters improve honey filling? Optimize Precision in Industrial Honey Machinery

- How many types of filling machines are there? A Guide to Choosing the Right Equipment

- How does an automated honey filling machine provide technical assurance? Scale Your Commercial Honey Distribution

- What is a quantitative filling machine? Achieve Precise, Automated Filling for Your Products

- What are the benefits of using proper honey bottling equipment? Elevate Your Product Quality and Profitability

- What role does the nozzle design play in honey filling machines? Maximize Accuracy & Minimize Waste