To properly strain your honey, you must first separate it from the comb and then pass it through a filter, such as a nylon bag or cloth, into a clean, food-grade container. This process, often called the "crush and strain" method, relies on gravity to separate the pure honey from wax cappings and other debris. For best results, the honey should be warm, as cold honey is too thick to flow easily through a filter.

The core principle of straining honey is simple: separate liquid honey from solid wax. The key to doing this effectively, especially for small-scale beekeepers, is to ensure the honey is warm enough to flow freely through your chosen filter without overheating and damaging its natural qualities.

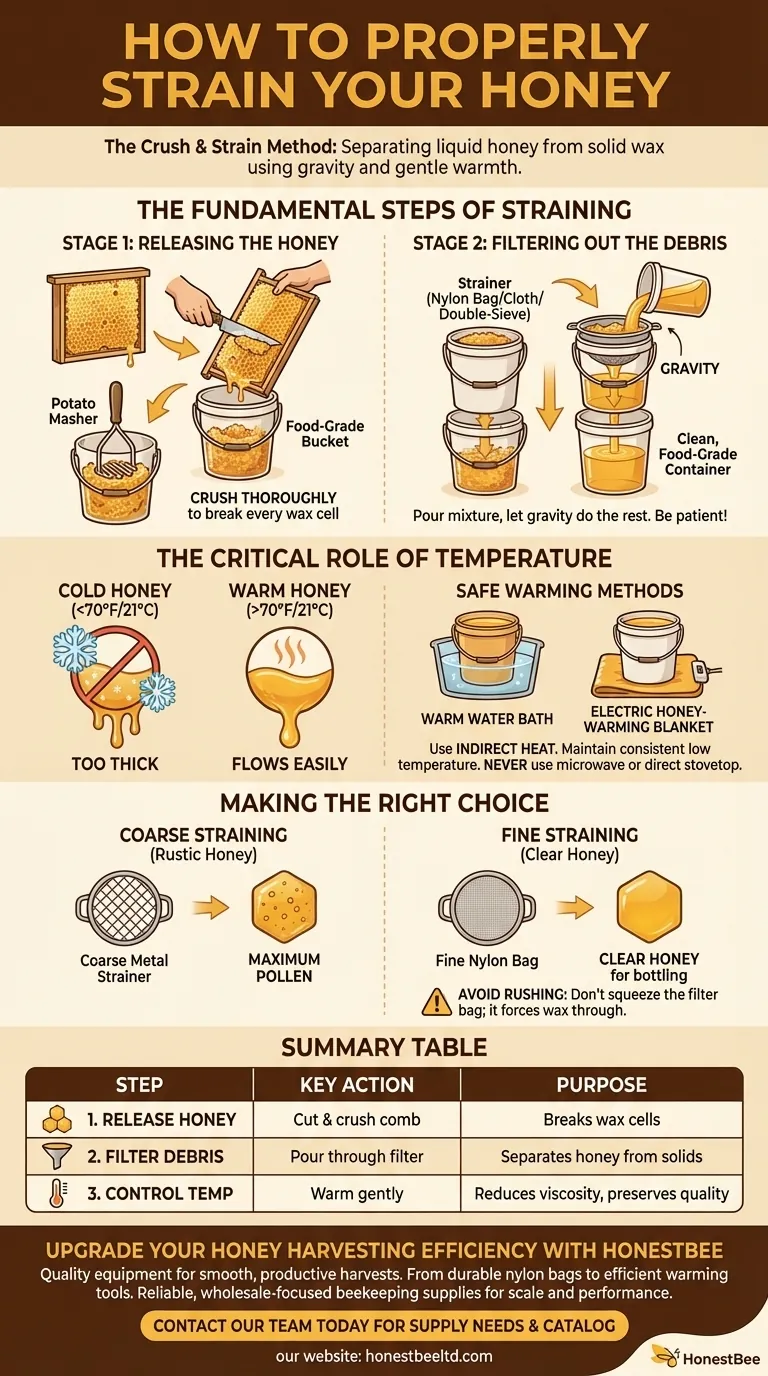

The Fundamental Steps of Straining Honey

The crush and strain method is straightforward and doesn't require expensive equipment, making it ideal for hobbyists. It involves two primary stages: releasing the honey from the comb and then filtering it.

Stage 1: Releasing the Honey

Before you can strain anything, you must get the honey out of the wax comb. First, cut the comb out of the wooden frames and place it into a large, food-grade bucket or container.

Using a clean utensil like a large spoon or a potato masher, crush the comb thoroughly. Your goal is to break open every wax cell to allow the honey to flow out.

Stage 2: Filtering Out the Debris

Once the comb is crushed, you can set up your filtering system. This typically involves a second food-grade bucket with a strainer placed over the top.

Common filter materials include nylon straining bags, cheesecloth, or specially designed double-sieve honey strainers. Pour the entire mixture of crushed comb and honey into the filter. Gravity will do the rest, though it may take several hours for all the honey to drip through.

The Critical Role of Temperature

Attempting to strain cold, thick honey is an exercise in frustration. The honey's viscosity, or thickness, is highly dependent on its temperature.

Why Warming Honey is Necessary

Honey that is below 70°F (21°C) is often too thick to pass through a fine filter. Gently warming the honey lowers its viscosity, allowing it to flow smoothly and separate from the wax much more efficiently.

This step is especially crucial if you are harvesting in a cool climate or during colder months of the year.

Safe Methods for Gentle Warming

The goal is to warm the honey, not cook it. Overheating can destroy the beneficial enzymes and delicate flavors that make raw honey special.

Use indirect heat. You can place your bucket of crushed comb in a warm water bath or use an electric honey-warming blanket. Maintain a consistent, low temperature—just enough to make it fluid. Never use a microwave or direct stovetop heat.

Understanding the Trade-offs

The type of filter you choose directly impacts the final product. There is no single "best" way; it depends entirely on your goal.

Coarse vs. Fine Straining

A coarse filter, like a standard kitchen sieve, will remove large pieces of wax and debris but leave much of the natural pollen. This results in a more "rustic" honey that may crystallize faster.

A fine filter, such as a nylon bag or multiple layers of cheesecloth, will remove nearly all wax particles and most pollen, producing exceptionally clear, beautiful honey that stays liquid longer.

The Risk of Rushing the Process

Straining honey properly takes time. Be patient and let gravity do its work. Squeezing the filter bag can force small wax particles through the mesh, defeating the purpose of straining and resulting in a cloudy product.

Making the Right Choice for Your Goal

Your equipment and process should align with your desired outcome for the honey.

- If your primary focus is raw honey with maximum pollen: Use a single, coarse metal strainer to remove only the largest pieces of wax.

- If your primary focus is clear, liquid honey for bottling: Use a double-filter system, starting with a coarse sieve and finishing with a fine nylon strainer.

- If you are working in a cool environment: Pre-warming your honey isn't optional; it is the most important step for ensuring the honey flows properly.

Ultimately, the process of straining allows you to transform raw honeycomb into the pure, clean honey you intended to harvest.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| 1. Release Honey | Cut & crush comb in a food-grade bucket. | Breaks wax cells to free honey. |

| 2. Filter Debris | Pour mixture through a nylon bag or cloth strainer. | Separates pure honey from wax and solids. |

| 3. Control Temperature | Warm honey gently (e.g., warm water bath). | Reduces viscosity for easy straining; preserves quality. |

Upgrade Your Honey Harvesting Efficiency with HONESTBEE

As a commercial apiary or beekeeping equipment distributor, you understand that quality equipment is key to a smooth, productive harvest. The right straining tools—from durable nylon bags to efficient honey-warming blankets—can save time and ensure a superior final product.

HONESTBEE specializes in supplying reliable, wholesale-focused beekeeping supplies designed for scale and performance. Let us help you equip your operation for success.

Contact our team today to discuss your supply needs and explore our full product catalog.

Visual Guide

Related Products

- Conical Nylon Honey Strainer Filter Bag for Beekeeping and Honey Filtration

- Stainless Steel Double Layer Honey Strainer Sieve Filters

- Honey Concentrating and Filtering Dehumidifier Machine 2T Capacity for Honey

- 10L Stainless Steel Electric Honey Press Machine

- Electric Honey Press Machine for Squeezing Honey Comb Press Equipment

People Also Ask

- How do you strain honey at home? A Step-by-Step Guide to Pure, Raw Honey

- What size mesh for straining honey? Master the Two-Stage System for Clean, Raw Honey

- What are the selection criteria for propolis centrifugation and filtration consumables? Ensure Purity and Bioactivity

- What is the method for processing honey from top bar hives? A Guide to Simple Crush & Strain

- What cloth for straining honey? The Best Materials for Clean, High-Quality Honey