Styrofoam beehives primarily improve overwintering success by providing superior thermal insulation. This stable environment drastically reduces the energy a honeybee colony must expend to stay warm, directly lowering their food consumption and minimizing the lethal risks of internal moisture and condensation.

The core challenge for a honeybee colony in winter is not just the cold, but a battle of energy and moisture management. Styrofoam hives give the bees a significant advantage by creating a warm, dry interior that conserves their vital resources.

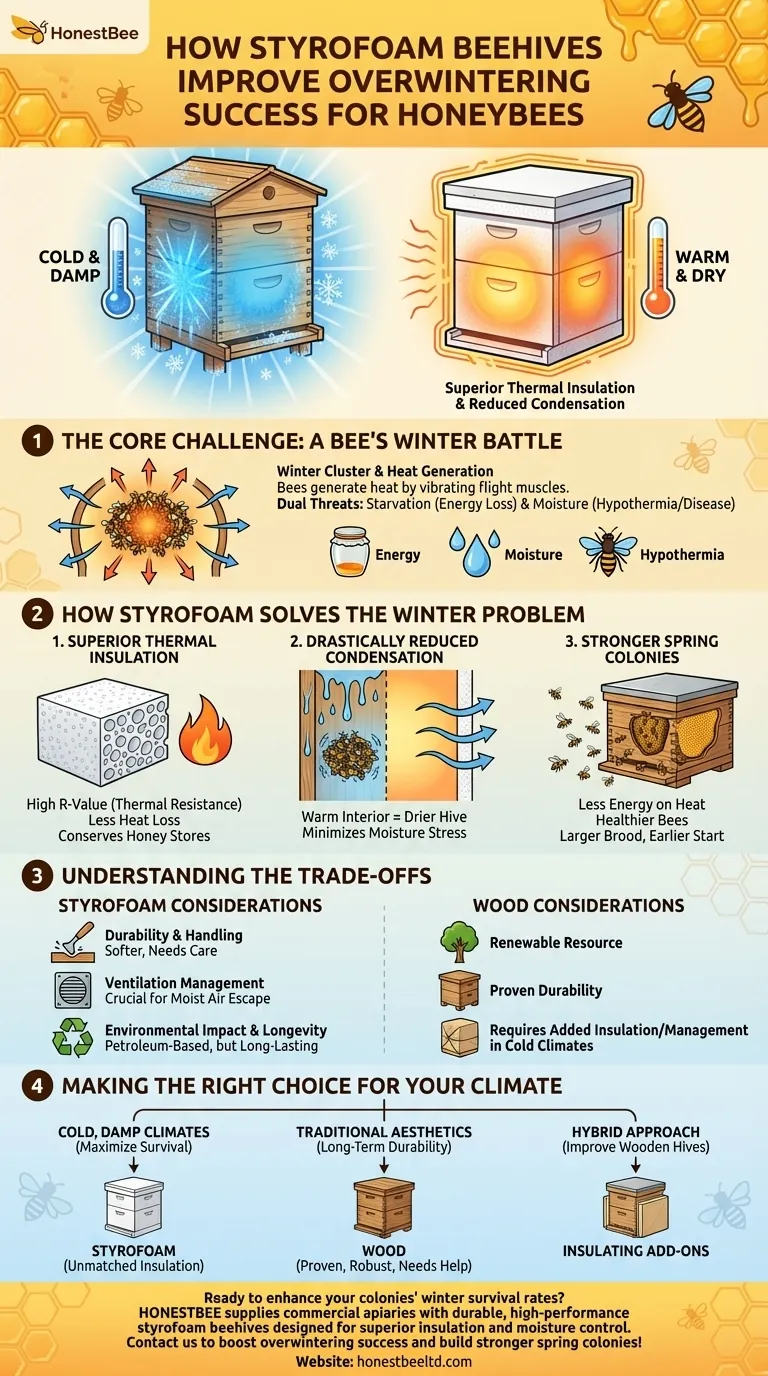

The Core Challenge: A Bee's Winter Battle

To understand why hive material matters, we must first understand how a colony survives the winter. Their strategy is a delicate balance of heat generation and resource conservation.

The Winter Cluster and Heat Generation

During cold months, honeybees form a tight winter cluster inside the hive. Bees on the outer layer insulate the group while bees in the center generate heat by vibrating their flight muscles.

The goal is to keep the center of the cluster, where the queen resides, at a stable temperature, especially after she begins laying eggs again in mid-winter.

The Dual Threats: Starvation and Moisture

This heat generation consumes immense energy, which comes from their stored honey stores. If the hive is poorly insulated, the bees must burn through their honey faster just to stay warm, increasing the risk of starvation before spring.

Simultaneously, the bees' respiration and the warm, moist air they create can condense on cold inner surfaces of the hive. This condensation can drip down onto the cluster, chilling them and leading to hypothermia, or it can foster an environment for diseases like Nosema.

How Styrofoam Solves the Winter Problem

A polystyrene (styrofoam) hive body directly counteracts the two primary threats to an overwintering colony. Its material properties create a much more forgiving internal environment compared to traditional wood.

Superior Thermal Insulation

The defining feature of styrofoam is its high R-value, or thermal resistance. It insulates significantly better than the solid wood used in traditional Langstroth hives.

This means far less heat generated by the cluster is lost to the outside air. The bees do not have to work as hard, allowing them to conserve their precious honey reserves for longer.

Drastically Reduced Condensation

Because the styrofoam is such a good insulator, the interior walls of the hive stay warmer. They are more likely to remain above the dew point, preventing the warm, moist air from the cluster from condensing into water droplets.

This creates a drier and healthier hive. A dry bee is a warm bee, and a dry hive mitigates the risk of moisture-related stress and disease.

Stronger Spring Colonies

Colonies that use less energy on heat production and face less moisture stress emerge from winter stronger and healthier. They often have more bees and a larger brood nest earlier in the season, giving them a critical head start for the spring nectar flow.

Understanding the Trade-offs

While highly effective for overwintering, styrofoam hives are not without their considerations. Objectivity requires acknowledging their potential downsides.

Durability and Handling

Styrofoam is softer and less durable than wood. It can be easily damaged by hive tools during inspections. It is also more susceptible to damage from pests like wax moths or even rodents if not properly protected.

Ventilation Management

The excellent insulation of styrofoam makes proper ventilation crucial. Without an avenue for moist air to escape, even a styrofoam hive can have moisture issues. Many beekeepers use screened bottom boards or upper entrances to ensure adequate air exchange.

Environmental Impact and Longevity

Wood is a renewable resource, whereas polystyrene is a petroleum-based plastic. However, high-density, well-maintained styrofoam hives can last for many years, and their impact must be weighed against the resources lost when a colony dies in a less-insulated hive.

Making the Right Choice for Your Climate

Your decision on hive material should be based on your specific goals, climate, and beekeeping philosophy.

- If your primary focus is maximizing winter survival in cold, damp climates: Styrofoam is arguably the superior choice due to its unmatched insulation and moisture control.

- If your primary focus is long-term durability and traditional aesthetics: Wood is a proven, robust material, but be prepared to assist your bees with insulation wraps or moisture-wicking quilt boxes in winter.

- If you want a hybrid approach to improve your wooden hives: Consider adding insulating foam boards under the outer cover or wrapping the hives to gain some of the thermal benefits without a full switch.

Ultimately, successful overwintering depends on understanding the principles of heat and moisture, allowing you to make the best decision for your bees.

Summary Table:

| Benefit of Styrofoam Beehives | Key Impact on Overwintering |

|---|---|

| Superior Thermal Insulation | Reduces energy expenditure, conserves honey stores, lowers starvation risk |

| Drastically Reduced Condensation | Creates a drier hive, minimizes hypothermia and disease (e.g., Nosema) |

| Stronger Spring Colonies | Healthier bees, larger brood nests, earlier start for spring nectar flow |

Ready to enhance your colonies' winter survival rates? HONESTBEE supplies commercial apiaries and beekeeping equipment distributors with durable, high-performance styrofoam beehives designed for superior insulation and moisture control. Let us help you boost overwintering success and build stronger spring colonies. Contact us today to discuss wholesale options and optimize your beekeeping operation!

Visual Guide

Related Products

- Professional Galvanized Hive Strap with Secure Locking Buckle for Beekeeping

- Premium Ventilated Goatskin Beekeeping Gloves with Full 3-Layer Mesh Sleeve

- HONESTBEE Professional Hive Top Bee Feeder Feeding Solution

- Wooden Bee Brush with Double-Row Horsehair Bristles

- Langstroth Screen Bottom Board for Beekeeping Wholesale

People Also Ask

- What are the types of Emlocks available? Choose the Right Strap for Hive Security

- How can a beehive be physically secured against harsh winter weather? Expert Winterizing Strategies for Your Apiary

- How should a cam buckle strap be installed for optimal performance? Master the Leverage for Maximum Tension

- What is the best length for straps used around beehives? Why 12 Feet is the Industry Standard

- What are hive straps and why are they used? Secure Your Hives Against Wind, Predators, and Transport