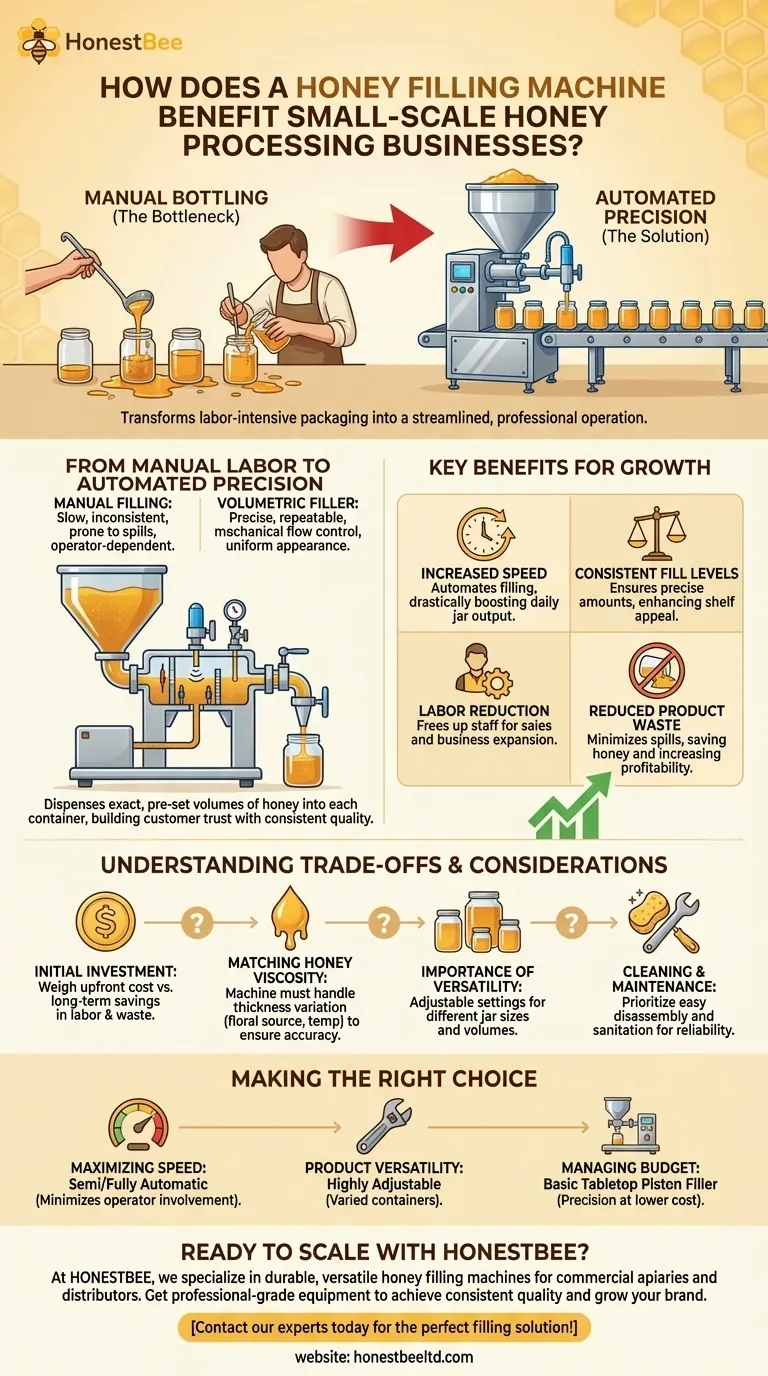

For the small-scale honey producer, a honey filling machine is a pivotal investment that transforms the packaging process from a labor-intensive bottleneck into a streamlined, professional operation. By automating the dispensing of honey into jars, these machines drastically increase production speed, ensure every jar has a consistent, accurate fill level, and significantly reduce the manual labor required.

The core issue for a growing honey business is not just making more honey, but packaging it efficiently and professionally. A filling machine addresses this directly, shifting your focus from the tedious task of bottling to the strategic goals of brand growth and market expansion.

From Manual Labor to Automated Precision

For many small producers, the final step of getting honey into the jar is the most time-consuming and inconsistent part of the entire process. This is the primary operational challenge that a filling machine is designed to solve.

The Bottleneck of Manual Filling

Manually filling jars is slow and prone to error. Spills create waste, inconsistent fill levels look unprofessional on a retail shelf, and the process requires a significant amount of an operator's time and attention.

As your business grows, manual filling quickly becomes the limiting factor that prevents you from meeting increased demand.

How a Volumetric Filler Works

A honey filling machine provides a precise, repeatable solution. Honey is held in a hopper and flows to a filling nozzle when the machine is activated.

Internal sensors and valves control the flow, dispensing an exact, pre-set volume of honey into each container. This mechanical precision eliminates the guesswork and variability of manual pouring.

The Impact on Product Consistency

When every jar contains the exact same amount of honey, it builds customer trust and reinforces brand quality. Consistent fill lines create a uniform, professional appearance on the shelf, which is critical for competing with larger brands.

This consistency also ensures you are not giving away product through over-filling or short-changing customers with under-filled jars.

Understanding the Trade-offs and Key Considerations

While the benefits are clear, investing in a filling machine requires careful thought. It's not just about buying a piece of equipment; it's about integrating a tool that fits your specific product and operational scale.

The Initial Investment

The most significant hurdle is the upfront cost. For a small business, this can be a substantial capital expenditure. You must weigh this cost against the long-term savings in labor, reduced product waste, and increased production capacity.

Matching the Machine to Your Honey

Honey's viscosity (its thickness and resistance to flow) varies greatly depending on its floral source, temperature, and moisture content. A machine must be able to handle the specific viscosity of your honey to ensure accuracy and prevent strain on the motor.

The Importance of Versatility

Small-scale producers often offer a variety of products, from small taster jars to large family-size containers. A valuable machine will have adjustable settings to easily accommodate different jar sizes and volumes. This adaptability ensures the machine can grow with your product line.

Cleaning and Maintenance

A machine that is difficult to disassemble and clean can create new bottlenecks. Look for designs that prioritize sanitation, with easy access to all parts that come into contact with the honey. Regular maintenance is also crucial for long-term reliability.

Making the Right Choice for Your Business

Choosing the right machine depends entirely on your specific operational goals and product offerings.

- If your primary focus is maximizing speed and efficiency: Prioritize a semi-automatic or fully automatic machine that minimizes operator involvement.

- If your primary focus is product versatility: Choose a machine with highly adjustable settings for both volume and container size.

- If your primary focus is managing a tight budget: Consider a more basic, tabletop piston filler that provides precision without the high cost of advanced automation.

Ultimately, the right honey filling machine transforms packaging from a daily chore into a strategic asset that enables your business to scale.

Summary Table:

| Benefit | Description |

|---|---|

| Increased Speed | Automates the filling process, drastically boosting daily jar output. |

| Consistent Fill Levels | Ensures every jar has the same precise amount, enhancing shelf appeal. |

| Labor Reduction | Frees up staff from manual pouring to focus on sales and business growth. |

| Reduced Product Waste | Minimizes spills and over-filling, saving honey and increasing profitability. |

Ready to scale your honey production with the right equipment?

At HONESTBEE, we specialize in supplying durable, versatile honey filling machines and other essential beekeeping supplies to commercial apiaries and distributors. Our wholesale-focused operations mean you get professional-grade equipment that fits your budget and operational needs, helping you achieve consistent quality and grow your brand.

Contact our experts today to find the perfect filling solution for your business!

Visual Guide

Related Products

- Economy Small Honey Filling Machine Honey Bottle Filler Packaging Machine

- Commercial Rotary Honey Filling Machine for Production

- Small Honey Filling Machine Sachet Packing Equipment Single Nozzle

- Precision Automated Packaging Turntable Honey Spoon Filling Sealing Packing Machine

- Double Wall Honey Heating Stirring Homogenizer Mixing Machine with Various Capacity

People Also Ask

- How does the piston filling principle work in honey filling machines? Achieve Precise, High-Viscosity Filling

- Why are industrial automated filling and packaging machines critical for bee pollen? Protect Potency and Scale Output

- How does the implementation of automated honey-filling machines address the challenge of rising production costs? Achieve Scalability and Precision

- What role do high-precision filtering and filling machines play in the post-harvest treatment of stingless bee honey?

- What is the purpose of the film roller in a honey stick machine? Prevent Spillage & Ensure Perfect Seals

- What core production challenges are addressed by industrial-grade honey-filling machines? Scaling Your Honey Brand.

- What are the advantages of using a honey stick machine? Boost Efficiency & Expand Your Confectionery Line

- Why is high-performance honey filling and packaging equipment essential? Boost Efficiency & Brand Value