In essence, a honey filtering machine works by gently heating raw honey to reduce its viscosity and then passing it through a series of progressively finer mesh screens. This process systematically removes physical impurities such as wax particles, bee parts, and other debris, resulting in a clear, clean honey that is ready for bottling and sale.

The core function of a honey filtering machine is not just to clean honey, but to standardize its quality for the market. It's a tool for transforming raw, variable honey into a consistent, visually appealing product by controlling clarity and texture.

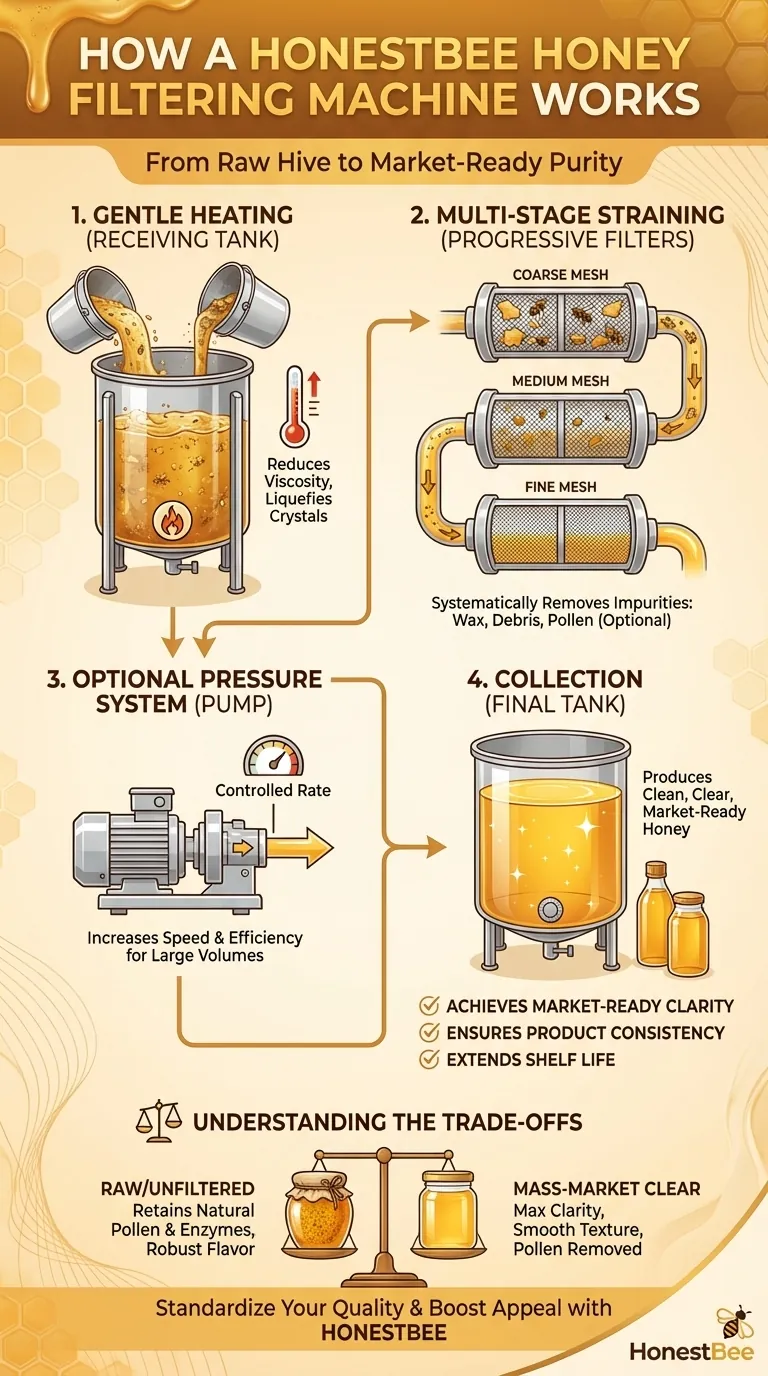

The Core Filtration Process: A Step-by-Step Breakdown

A honey filtering machine automates and refines what beekeepers have traditionally done by hand. The goal is to produce a pure, liquid honey free from the natural debris of the hive.

Step 1: Gentle Heating for Flow

The first step is to pour the harvested honey into a receiving tank. This tank often includes a gentle heating element.

This is not for cooking the honey, but to liquefy any sugar crystals that have formed and to slightly reduce the honey's natural thickness. This makes the honey flow much more easily through the filters.

Step 2: Multi-Stage Straining

Once warmed, the honey is moved through a series of filters or mesh screens.

These screens are arranged in a progressively finer sequence. The first screen might catch large pieces of wax, while subsequent, tighter screens trap smaller particles like pollen grains or other fine debris.

Step 3: Optional Pressure Systems

To improve efficiency, some advanced machines use pressure systems.

A pump forces the honey through the filters at a controlled rate. This speeds up the entire process, which is especially valuable for larger commercial operations processing significant volumes of honey.

Step 4: Collection of Purified Honey

After passing through the final, finest filter, the honey emerges clean and clear. It flows into a final collection tank, now free of solid impurities and ready for bottling.

Why Filtration is a Critical Step

Filtering does more than just remove bee wings and wax. It fundamentally changes the product's characteristics to meet market expectations.

Achieving Market-Ready Clarity

The primary driver for filtration is aesthetics. Consumers associate clarity with purity.

Filtering removes suspended particles and microscopic sugar crystals that can cause honey to appear cloudy or grainy. A clear, sparkling honey has a higher perceived quality on the shelf.

Ensuring Product Consistency

Filtration helps create a uniform product. It removes random debris and air bubbles, ensuring every jar has the same smooth texture and appearance. This consistency is crucial for building a reliable brand.

Extending Shelf Life

By removing impurities and potential nucleation points for crystallization, filtration can help prolong the time honey remains in a liquid state. This contributes to a longer, more stable shelf life.

Understanding the Trade-offs: Clarity vs. "Raw" Honey

While filtration produces a beautiful product, it's essential to understand what can be lost in the process. The choice of how much to filter is a significant decision for any beekeeper.

The Cost of Purity: Pollen Removal

Very fine filters, often used in large-scale industrial processing, can remove beneficial pollen grains.

Many consumers specifically seek out "raw" or "unfiltered" honey because they value the presence of local pollen. Aggressive filtration removes this key differentiator.

The Power of Customization

Most honey filtering machines allow for customization. Beekeepers can swap out filter screens with different mesh sizes.

This allows them to precisely control the level of filtration, striking a balance between removing unwanted debris and retaining desirable elements like pollen.

The Impact on Flavor and Texture

Minimal straining (using a coarse filter) removes only the largest debris, leaving a product closer to its state in the hive. This honey may be cloudier and crystallize faster but is often considered to have a more robust and complex flavor profile.

Making the Right Choice for Your Honey

Your approach to filtration should be dictated by your end goal and your target customer. There is no single "best" method; there is only the right method for your specific product.

- If your primary focus is a crystal-clear product for mass-market appeal: Use a system with multiple, progressively finer filters to remove all visible particles.

- If your primary focus is selling "raw" or "unfiltered" honey: Use only a coarse strainer to remove the largest debris while retaining all-natural pollen and enzymes.

- If your primary focus is a balance of cleanliness and natural character: Use a medium-mesh filter that removes noticeable impurities but leaves much of the pollen intact.

Ultimately, understanding how a honey filtering machine works empowers you to produce a product that perfectly aligns with your goals.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Gentle Heating | Warms honey in a receiving tank. | Reduces viscosity, liquefies sugar crystals for easier flow. |

| 2. Multi-Stage Straining | Passes honey through progressively finer mesh screens. | Systematically removes wax, bee parts, and fine debris. |

| 3. Optional Pressure | Uses a pump to force honey through filters. | Increases processing speed and efficiency for large volumes. |

| 4. Collection | Gathers purified honey in a final tank. | Produces clear, clean honey ready for bottling and sale. |

Ready to standardize your honey quality and boost your brand's market appeal?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with robust, high-efficiency honey filtering machines designed for wholesale operations. Our equipment helps you achieve the perfect balance of clarity, purity, and natural character your customers demand.

Contact our experts today to find the ideal filtering solution for your production scale and brand goals.

Visual Guide

Related Products

- Professional Thermostatic Conical Honey Melter

- Pneumatic Double Nozzle Honey Filling Bottling Packaging Machine

- Honey Concentrating Vacuum Heating Thickening Machine Dehumidifier for Honey

- Electric 8 Frame Honey Spinner Extractor Equipment for Beekeeping

- 8-Frame Electric Self-Reversing Honey Extractor Spinner for Commercial Honey Extraction Equipment

People Also Ask

- What is the overall importance of using the right equipment in honey filtering? Boost Quality & Marketability

- What role does industrial honey filtration play? Enhance Market Value with Professional Processing Equipment

- What is the function of industrial high-mesh screens in stingless bee cerumen pretreatment? Maximize Purity and Yield

- How do professional filtration and centrifugation equipment contribute to honey quality for commercial markets?

- What advantages do industrial honey filtration and processing systems offer? Scale Your Quality and Output

- How do honey refining and filtering machines enhance value? Elevate Purity & Market Price in Post-Processing

- What is the function of high-precision Sieving Equipment in honey post-processing? Master Honey Purification

- What is the purpose of using a standard grading sieve before filling propolis powder? Optimize Capsule Quality