At its core, a honey refractometer works by measuring the bending of light. As light passes through a honey sample, its path is altered based on the honey's density, which is directly determined by its sugar concentration. The device uses a prism and a calibrated scale to translate this change in light into a precise measurement of moisture content.

The real purpose of a honey refractometer is not just to measure light, but to provide a definitive answer to a critical question: "Is this honey stable and ready for harvest?" It turns an abstract scientific principle into a simple, actionable quality control metric.

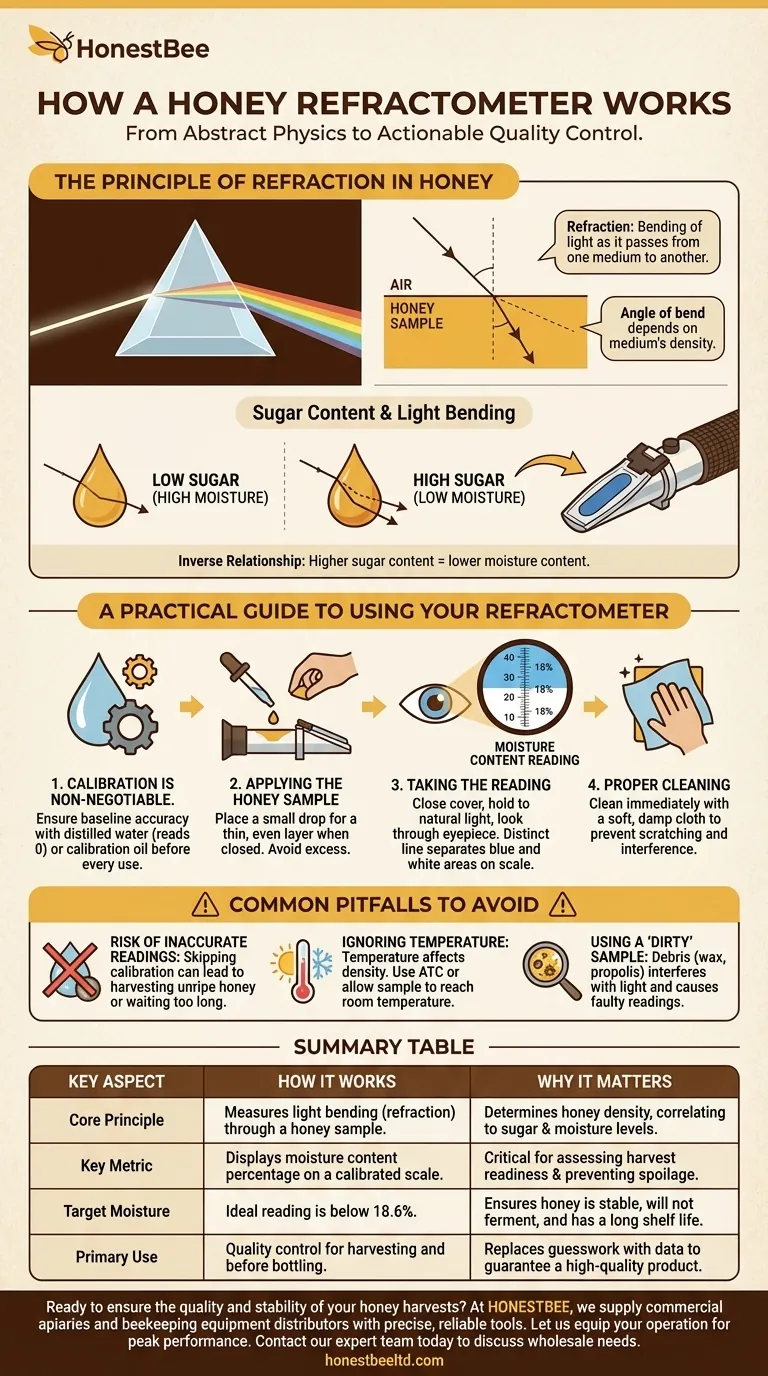

The Principle of Refraction in Honey

To understand how a honey refractometer provides its reading, we first need to grasp the underlying physics. The process is straightforward and relies on a predictable property of light.

What is Refraction?

Refraction is the bending of light as it passes from one medium to another, like from air into water. You see this phenomenon when a straw in a glass of water appears bent at the surface.

The angle of this bend depends on the density of the medium. The denser the medium, the more the light slows down and bends.

How Sugar Content Affects Light

Honey is essentially a supersaturated solution of sugars in water. A higher sugar content makes the honey denser.

When light passes through the refractometer's prism and into the honey sample, it bends more sharply in honey with high sugar concentration than it does in honey with a lower sugar concentration.

From Sugar to Moisture Content

The refractometer's scale cleverly uses an inverse relationship. High sugar content directly corresponds to low moisture content.

The device measures the degree of light bending (which indicates sugar level) but displays the result on a scale calibrated to show the percentage of water. This gives the beekeeper the exact metric they need to assess honey quality.

A Practical Guide to Using Your Refractometer

Correctly using the tool is essential for obtaining accurate, repeatable results. The process involves four simple but critical steps.

Step 1: Calibration is Non-Negotiable

Before every use, you must calibrate the device. This ensures your baseline is accurate. Most honey refractometers are calibrated with a drop of distilled water (which should read 0) or a special calibration oil.

Step 2: Applying the Honey Sample

Place a small drop of honey onto the clean prism surface. You only need enough to create a thin, even layer when the clear plate is closed.

Using too much honey can lead to an inaccurate reading and makes cleanup more difficult.

Step 3: Taking the Reading

Close the cover plate and hold the refractometer up to a natural light source. Look through the eyepiece.

You will see a scale, typically with a distinct line separating a blue area from a white area. The point where this line crosses the scale is your moisture content reading. If the line is blurry, twist the eyepiece to focus it.

Step 4: Proper Cleaning

Immediately after taking a reading, clean the prism and cover plate with a soft, damp cloth. Dried honey is difficult to remove and can scratch the prism, compromising future measurements.

Common Pitfalls to Avoid

While the tool is simple, a few common mistakes can undermine its accuracy. Being aware of these ensures you can trust your readings.

The Risk of Inaccurate Readings

Skipping calibration is the most common error. An uncalibrated refractometer can give a reading that is off by several percentage points, leading you to either harvest unripe honey that could spoil or wait too long to harvest.

Ignoring Temperature

Temperature can affect the density of honey and, therefore, the reading. Many modern refractometers have Automatic Temperature Compensation (ATC), but it's still best practice to allow the honey sample to reach room temperature before measuring for the most accurate result.

Using a "Dirty" Sample

Ensure your honey sample is free from wax, propolis, or other hive debris. Contaminants on the prism can interfere with the light, obscure the dividing line, and cause a faulty reading.

Making the Right Choice for Your Honey

Ultimately, using a refractometer is about replacing guesswork with data to ensure a high-quality, stable product.

- If your primary focus is harvesting readiness: Use the refractometer to test honey directly from the comb to confirm it has "cured" to a moisture level below 18.6% before you pull the supers.

- If your primary focus is quality control for selling: Regularly test your extracted and bottled honey to guarantee it meets industry standards and has a long shelf life, preventing fermentation and spoilage.

This simple tool empowers you to move from guessing to knowing, ensuring the quality and integrity of every jar.

Summary Table:

| Key Aspect | How It Works | Why It Matters |

|---|---|---|

| Core Principle | Measures light bending (refraction) through a honey sample. | Determines honey density, which correlates to sugar and moisture levels. |

| Key Metric | Displays moisture content percentage on a calibrated scale. | Critical for assessing harvest readiness and preventing spoilage. |

| Target Moisture | Ideal reading is below 18.6%. | Ensures honey is stable, will not ferment, and has a long shelf life. |

| Primary Use | Quality control for harvesting and before bottling. | Replaces guesswork with data to guarantee a high-quality product. |

Ready to ensure the quality and stability of your honey harvests?

At HONESTBEE, we supply commercial apiaries and beekeeping equipment distributors with the precise, reliable tools they need for success. A high-quality honey refractometer is essential for accurate moisture testing, protecting your product and your reputation.

Let us equip your operation for peak performance. Contact our expert team today to discuss your wholesale needs for refractometers and other essential beekeeping supplies.

Visual Guide

Related Products

- Precision Honey Refractometer Instrument for Quality Assessment

- Digital Honey Refractometer for Precision Measurement of Optimal Honey Quality

- HONESTBEE 3-Frame Manual Acrylic Honey Extractor

- electric honey extractor honey centrifuge 3 frame honey extractor stainless steel honey frame extractor

- Plastic Hand Crank 2 Frame Honey Extractor Low Price

People Also Ask

- How is a manual refractometer used to determine honey quality? Essential Moisture Control for Commercial Beekeeping

- Why is a high-precision refractometer considered essential for honey quality? Master Moisture Control for Stability

- What is the primary function of a desktop refractometer? Ensure Honey Quality and Prevent Fermentation

- What should be considered regarding the measurement range of a honey refractometer? Ensure Peak Honey Quality

- Why is a laboratory benchtop refractometer essential for honey? Secure Stability & Quality